Kaizen

12-Step Kaizen Toolkit

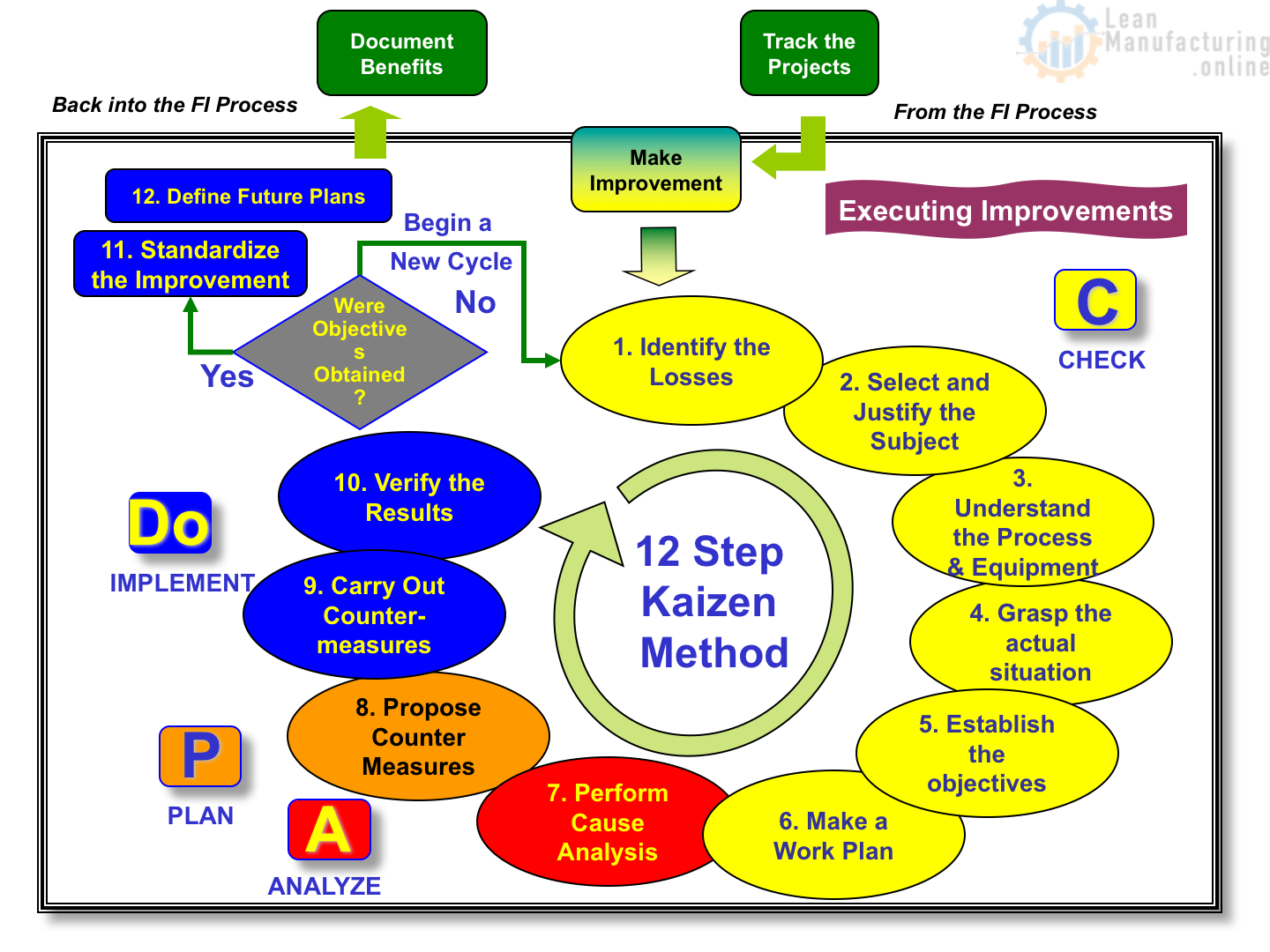

The full process described here: 12 Step Kaizen Story Step # Step Explanation Form Name 1 Identify The Situation 1) Charter Team 2) Collect the available Data 3) Classify The Losses Step 1 – Team Charter 2 Justify The Situation 1) Stratify The Losses 2) Select the Subject 3) Verify…

Read More »Deep KAIZEN for Quality Defects

Quality defect and rework losses are defined as: Material wasted by producing defective products that have to be scrapped; The time lost (less output) when reprocessing defective products that can be turned into good ones. Some typical examples of quality defects and rework Topping up containers outside the line when…

Read More »Deep Kaizen for Minor Stops – 7 Step Kaizen

How is a Minor Stop Defined? A machine stoppage is called a ‘minor stop’ when: the machine stops working for a short time; the machine can easily be restarted by removing or repositioning a workpiece; the machine can be restarted within a few seconds or minutes. The losses due to…

Read More »One slide Kaizen and Cap-Do (PDCA) cycle hybrid

Maximize the Overall Equipment Effectiveness, Process and Plants Through Uncompromising Elimination of Losses and Continuous Improvement of Performance. Step 1 – Identify The Situation Charter Team Collect available Data Classify Losses Step 2 – Justify The Situation Stratify Losses Select the Subject Verify Relevance to Site Master Plan Step 3 – Understand…

Read More »