OPL

One Point Lesson – OPL – Compressed Air Safety – Usage of restricted air guns for cleaning activities

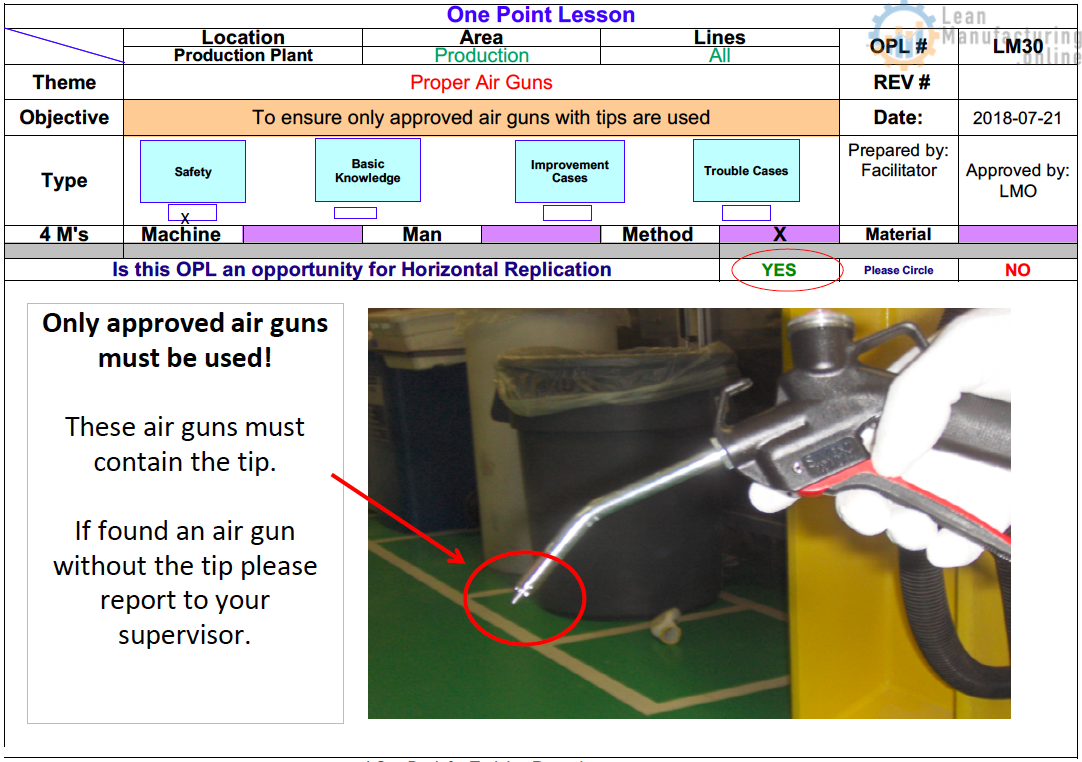

Usage of compressed air is very effective, however is very dangerous if not handled properly. Recommended to use air with restricting nozzle, reduces safety risk without loosing cleaning effectiveness. All approved air guns must have safety tip, if during pre-operational inspection found that air gun is missing nozzle, please report…

Read More »One Point Lesson – Flat Belts Inspection – Autonomous Maintenance

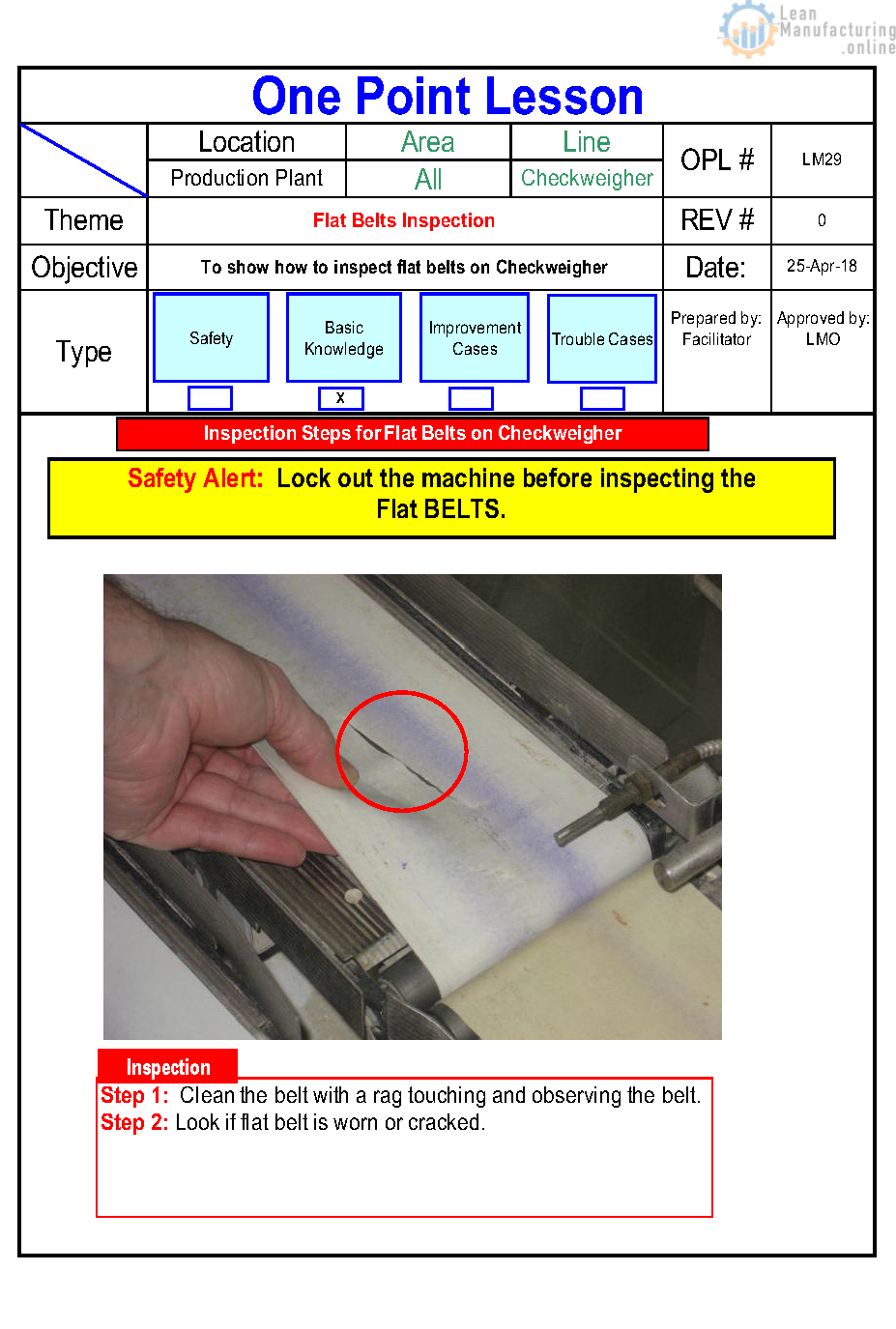

Step 1: Clean the belt with a rag touching and observing the belt. Step 2: Look if flat belt is worn or cracked.

Read More »Inspection Steps for Chains and Sprockets – Visual Standards Inspections

Step 1: Clean the sprocket with a rag touching and observing the sprocket. Step 2: Look for the following abnormalities: Worn teeth Misalignment Abnormality 1: Worn teeth teeth should not be rounded,teeth should not be chipped. Abnormality 2: Misalignment The sprocket must be aligned and perfectly perpendicular to the axis of…

Read More »Visual Controls: Autonomous Maintenance – OPL Chain – Inspection

Visual Controls are very useful tools for a quick inspection to determine the condition of assembly to avoid or reduce downtime. One Point Lesson below gives examples of accessible chain and timing belt drive inspections.

Read More »