Tools

Kaizen Event Planning in 7 Simple Steps

Kaizen events are a powerful tool for organizations looking to improve their processes and achieve continuous improvement. When planning and executing a successful kaizen event, it is essential to follow a systematic approach that involves defining the problem and goal, identifying the team, developing an agenda, preparing the team, conducting…

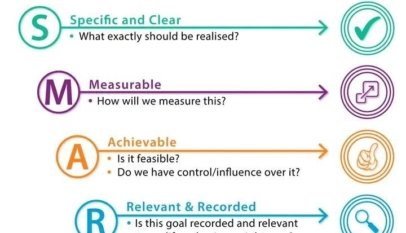

Read More »Mastering SMART Goals: A Guide to Effective Goal-Setting in Business

This indispensable guide breaks down the five key components of SMART goals - Specific, Measurable, Achievable, Relevant, and Time-bound - and provides practical examples, real-life case studies, and actionable strategies to help businesses transform their vision into reality. With its step-by-step approach, this book is your go-to resource for mastering…

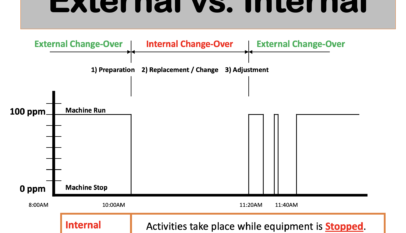

Read More »External activity vs. Internal activity – Knowing this can make a world of difference in the efficiency of your changeovers

Changeovers are required to ensure that we can satisfy the different needs of a customer. Reducing the time to do a changeover holds the key to how quickly we can respond to a customer’s needs. Also, quick changeover means less downtime, which translates to more efficiency, productivity, and parts! How…

Read More »Types of material replenishment systems

Material replenishment is a critical component of effective supply chain management. There are several types of material replenishment systems available, each with its own strengths and weaknesses. In this post, we will explore the different types of material replenishment systems including the Kanban System, Just-In-Time (JIT) System, Material Requirements Planning…

Read More »