Autonomous Maintenance

TPM Autonomous Maintenance Step 4 Lubrication Module. Part 2

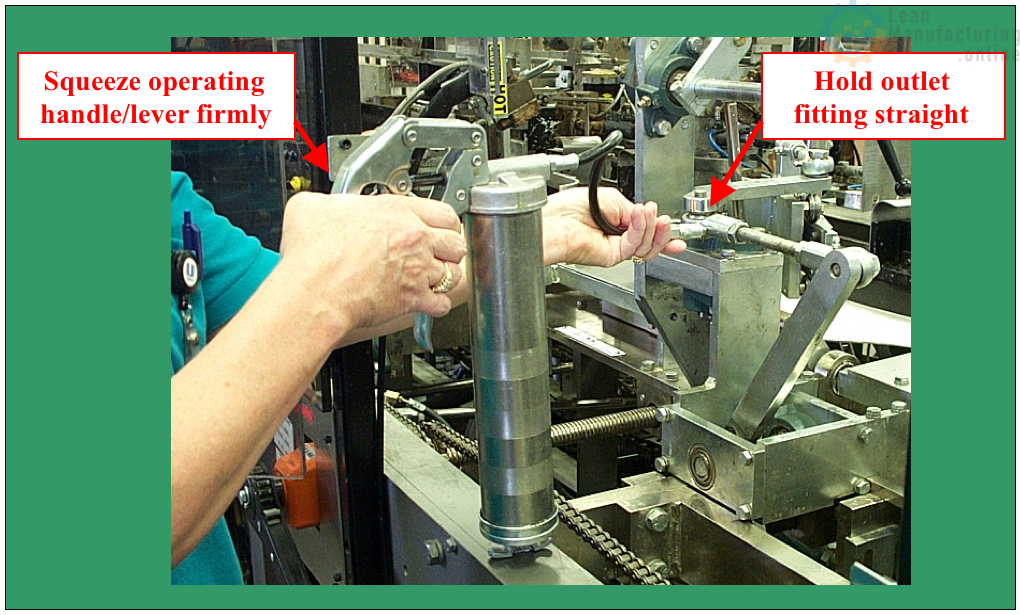

In-Line Air Lubricators These lubricators lubricate the air supply to air operated equipment. Do you work on any air operated equipment? Drip rates can be adjusted using the adjustment knob on top of the lubricator. Components Identified Air lubricators cannot be filled while pressurized. Pressure must be removed by activating…

Read More »TPM Autonomous Maintenance Step 4 Lubrication Module. Part 1

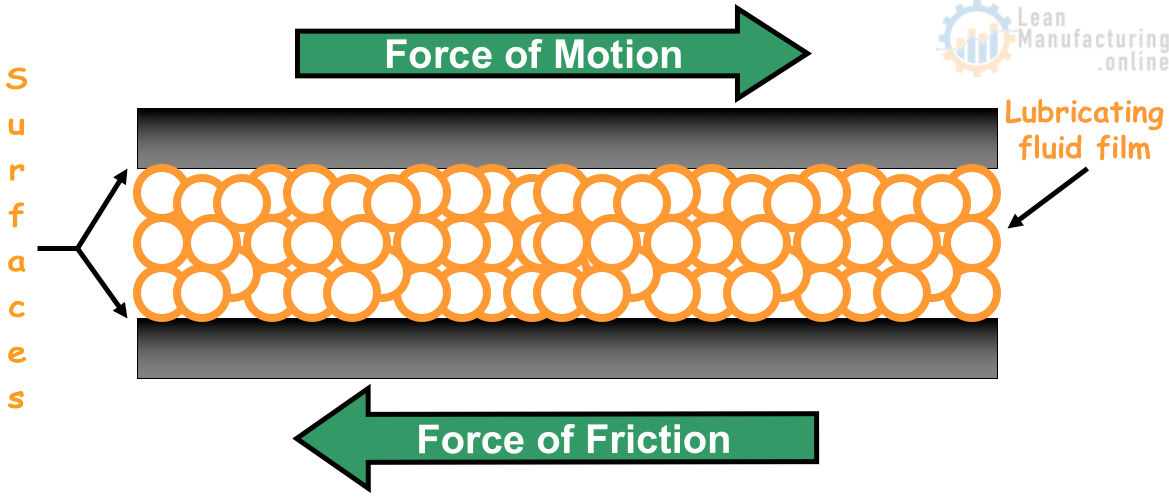

Purpose of Lubrication As shown in the figure, the lubricating fluid film between the two surfaces keeps the surfaces from making direct contact. The very small particles of the lubricating fluid in the film move over each other reducing the friction between the surfaces. Training Objectives Describe the purpose of…

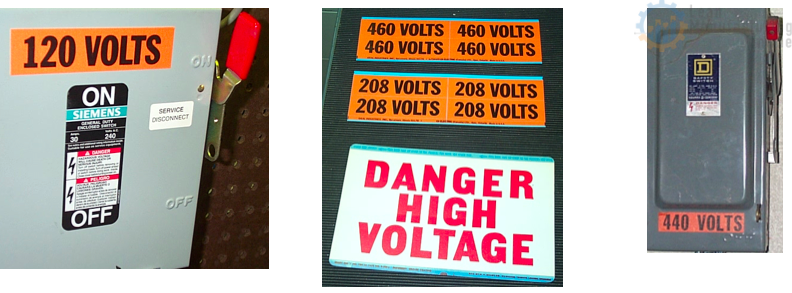

Read More »Electrical and Sensor Module – AM TPM training – World Class Manufacturing

Electrical and Sensor Module Objectives This module provides a basic electrical safety awareness and NOT technical electricity training. The module will provide the tools and ideas on what to do in case of electrical fire, what to visually inspect, and the abnormalities you may encounter in the plant. Operators will…

Read More »Inspection Standard Training for Conveyors

When it comes to the movement of materials, no piece of equipment is more commonly used than a Conveyor System. You will see that the packing lines and palletizers in our plant are highly dependant upon Conveyor Systems. In discussing Conveyors we will look at: What They Do and What…

Read More »