Autonomous Maintenance

Autonomous Maintenance Step 1

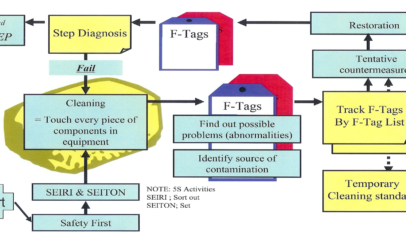

AM Step 1 Objectives Machine Reliability: Prevent Forced Deterioration Restore Latent Defects in Equipment Identify Source of Contaminants Skill Up: Understand machine Structures & Function Activity – Go to the Genba (Actual Place!): 1. Deep Cleaning 2. Discover Potential Problems Fuguai 3. Tagging 4. Tentative Action for SOC 5. Routine…

Read More »Autonomous Maintenance Step 2

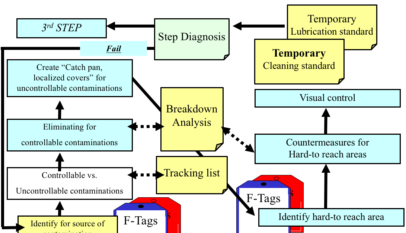

AM Step 2: Countermeasures for SOCs & HTAs Objective: Countermeasures for SOCs and HTAs Stated in other words: Prevent causes of dust, dirt, and leakageImprove places that are difficult to clean, inspect, and lubricateReduce the time required for cleaning, inspection, and lubrication AM Step 2 Sub-sections Step 2 Activities: Countermeasures…

Read More »6 Major Equipment Losses

SIX MAJOR EQUIPMENT LOSSES Major Stops Minor Stops Change-Over Loss Start-Up / Shut-Down Loss Speed Loss Quality Loss Definitions MAJOR STOPS Any stoppage that is greater than 10 minutes Note: is sometimes broken into Equipment Breakdown (Breakdown) and Procedural loss (Major Stops) Measures: Number of Occurrences and Duration (mins) MINOR…

Read More »What is a Breakdown?

The word “Breakdown” seems to be self-explanatory. Webster’s definition of a breakdown is:“ A failure to function, a function loss, failure to progress or have an effect”. When we apply it to equipment or assets, then anytime the equipment or asset fails to perform when required at design capacity and…

Read More »