Early Product Management

Designing-in factory-friendliness at the product development stage

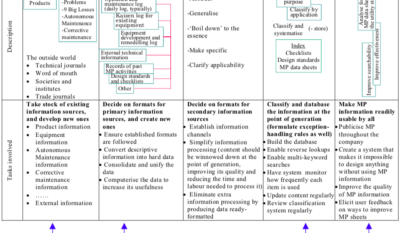

Before starting to design the product, identify any specific issues concerning the factory-friendliness of current products, and build the solutions to these issues into the design of the new product.

Read More »The anatomy of a Life-Cycle Costing system

The lower the sum of the cost of capital and the operating cost, the better. If the alternative proposal has a different output, the comparison is done using the cost per unit of output.

Read More »Setting up an MP information utilization system

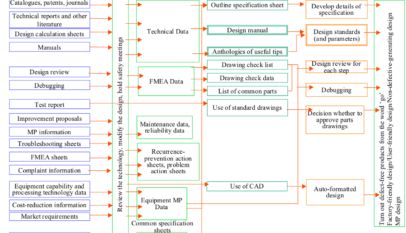

Identify sources of MP information Take stock of every potential source of MP information – old or new – and decide how useful it could be.For each information source, set up a system (e.g. MP data sheets) for gathering useful information in a usable format. Establish new information channels (primary…

Read More »Reviewing the overall Early Management process

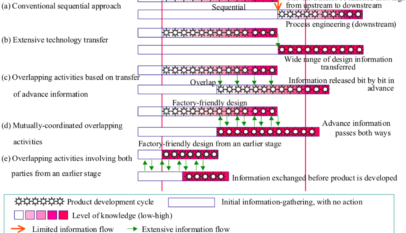

(1) Effect on LCC at each step It is said that 80% of the LCC of products and equipment is determined at the design stage (see Figure “Effect on Life Cycle Cost at Each Development Step”). Effect on LCC at Each Development Step (2) Using concurrent engineering to reduce the…

Read More »