Early Product Management

Conceptual Diagrams of Quality Function Deployment

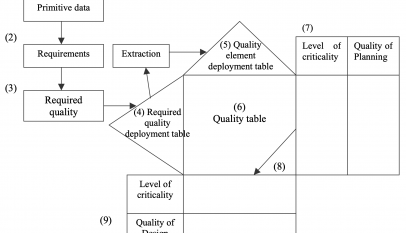

There are many different schemes for graphic representation of QFD, including triangular and rectangular layouts, which outside of Japan are sometimes called house block drawings. Diagrams in which a rectangular section is crowned with a triangular one are said to resemble a house and are sometimes referred to as a…

Read More »Primitive Data Transformation Sheet – QFD

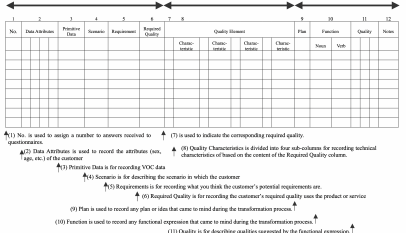

One convenient method for transforming VOC into required quality is to use a primitive data transformation sheet. A sample primitive data transformation sheet can be found at the end of the chapter entitled Quality Deployment Methods (1) and the content of that sheet is illustrated in Diagram “Primitive Data Transformation…

Read More »Establishing a Scenario – QFD

That is why the main answers you will have to provide to complete your scenario will be who, when, and where.

Read More »The Voice of the Customer

Listening to the “voice of the customer” (VOC) is an important part not just of customer satisfaction activities such as those initiated under the Malcolm Baldrige National Quality Award but also in any quality assurance program. Any requirement that comes from the customer can be analyzed as VOC data capable…

Read More »