1. OPLs

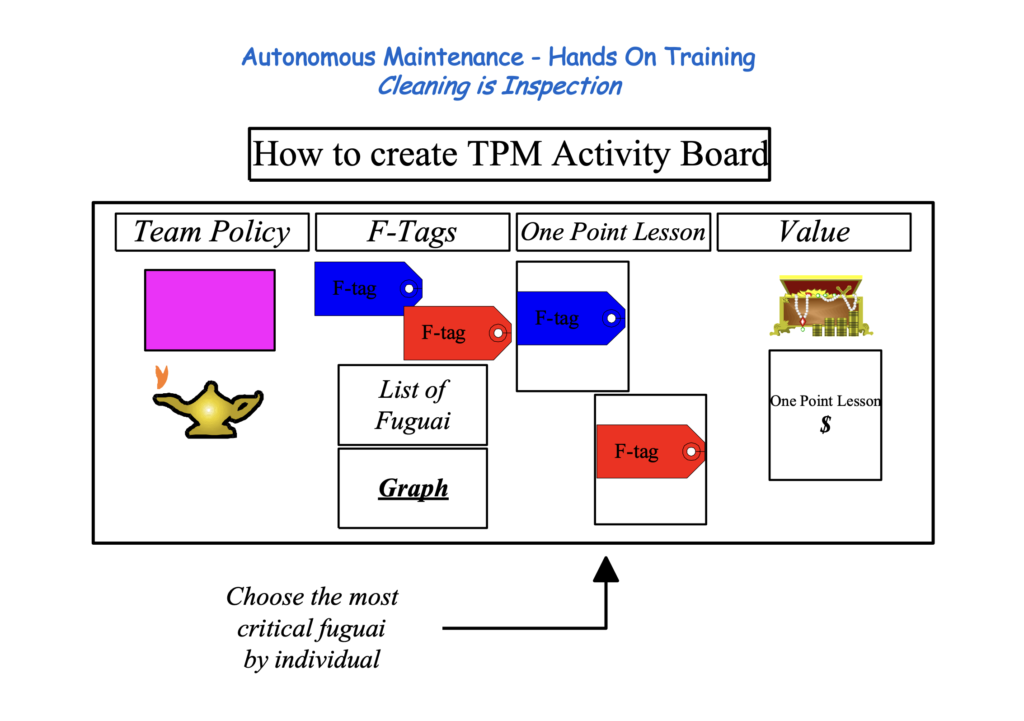

2. Activity Boards

3. F-Tags

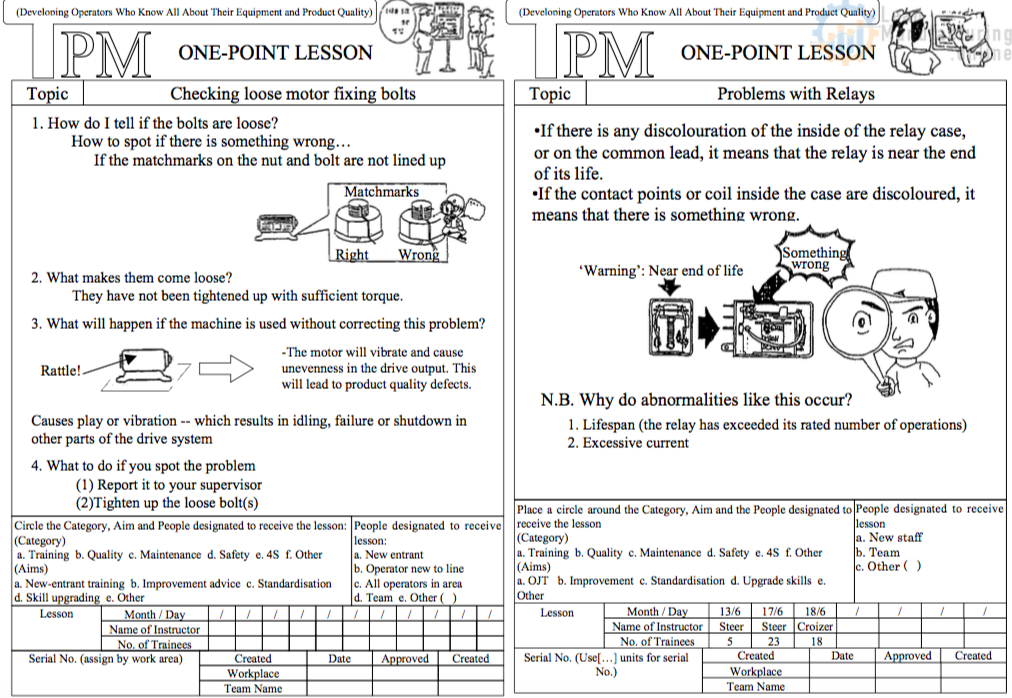

One Point Lesson (OPL)

What is an OPL?

- a tool to convey information

- designed to enhance knowledge and skills in a short time, at the right time, whenever needed

- to upgrade levels of expertise by having individuals study, learn and then train others in the knowledge or skill

Who creates OPL?

- Everyone!

- Operators, Mechanics, Managers, Supervisors, Engineers, Office staff, etc.

- We are all responsible for upgrading the knowledge and skills of each other

When Do You Create A OPL?

- Anytime it makes sense to convey some knowledge or skill to others

- Safety, Health or Environmental issues

- Quality requirements/improvements

- Productivity requirements/improvements

- To reinforce existing procedures

- To explain new procedures or equipment

- Anything from how to wash hands to how to handle a changeover on a specific line

Process For Creating an OPL

- Encounter a situation requiring knowledge/skill transfer

- Obtain a blank OPL form

- Write up OPL

- Submit into OPL Database (provide copy to TPM admin or Process Excellence)

- Train relevant employees and have them sign the OPL

- Post OPL in Department for 30 days

- After 30 days place OPL in Department binder

Guidelines for writing an OPL

- Make it clear

- “A picture is worth a thousand words”

- (80% visual, 20% words)

- Know who your audience is

- If possible show correct vs. incorrect process / method / etc. (see next slide)

- Keep it simple

- Hand drawn where possible

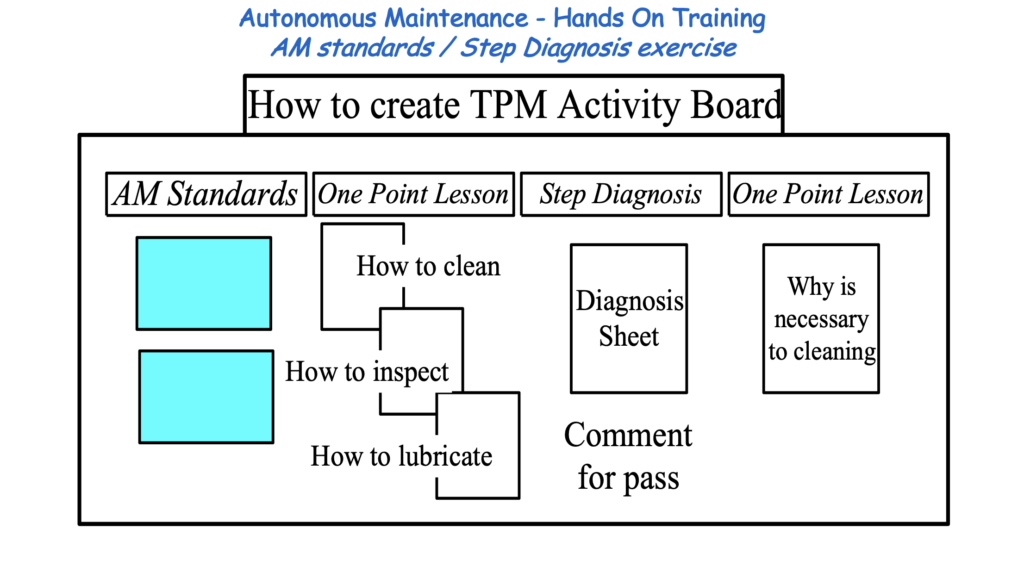

Activity Boards

Activity Board Objectives

- Visual representation of our goals, activities and results

- Consistent method of communication

- Through construction of an Activity Board, Teams’ understanding of content is reinforced

ACTIVITY BOARDS ARE THE TRAINING MATERIAL

Components

- Show Team Vision, Methodology, Pictures, Names, Roles, Goals, Results, Safety Message, Team Learnings

- Board must have a logical flow, be easy to read and understand

- Digital pictures and computer generated information is OK. However, preferred method Hand drawn.

- All Team Members should participate in presenting the board

Activity Board Guidelines

- Colours & Patterns grab attention (see next slide)

- Easy to update helps keep board “alive”

- Prominent location is desirable

- Title or purpose for board should be bold and very clear

- Visual information is preferred instead of writing (80% visual / 20% words)

- Focus on the Learnings

The Use of Colour

- PRETTY vs. PROFESSIONAL

- Colour is a Tool used for improved communication

- Do not use colour for the sake of colour

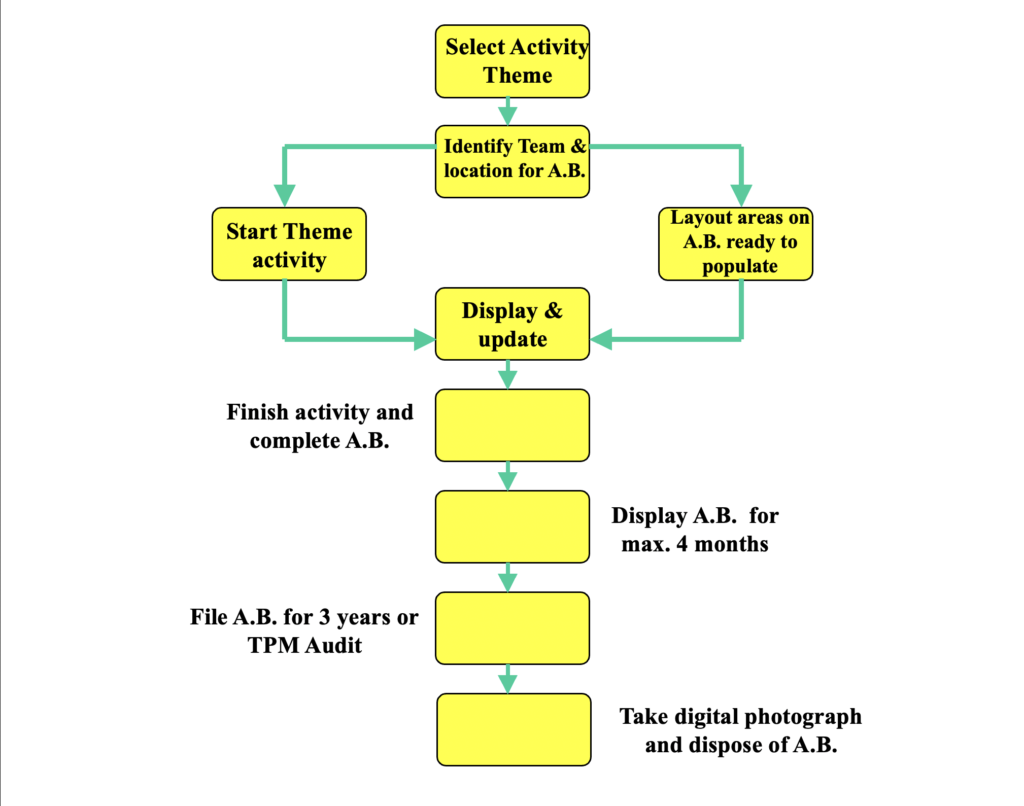

Activity Board Lifecycle

Top 10 Reasons for Failure:

- Boards not updated – discipline breakdown, lack of pride, low priority for TPM activities

- Boards are used as Display Boards – misunderstanding of the Activity Board purpose

- Board is located in a remote, inaccessible area – no opportunity to show progress

- Boards are located in dirty, wet areas – bad advert for TPM

- Boards have no clear purpose or vision – lack of discipline and training up front

- Boards are locked away – difficult to access leads to apathy

- Boards are too intricate – huge effort to maintain leads to no maintenance

- Boards have no owners – leads to out of date info, lack of maintenance etc

- Boards are very individual – no overall guidance, perception that TPM is not organized

- Boards are seen as a gimmick – lack of training, education and Management participation

Activity Board Examples

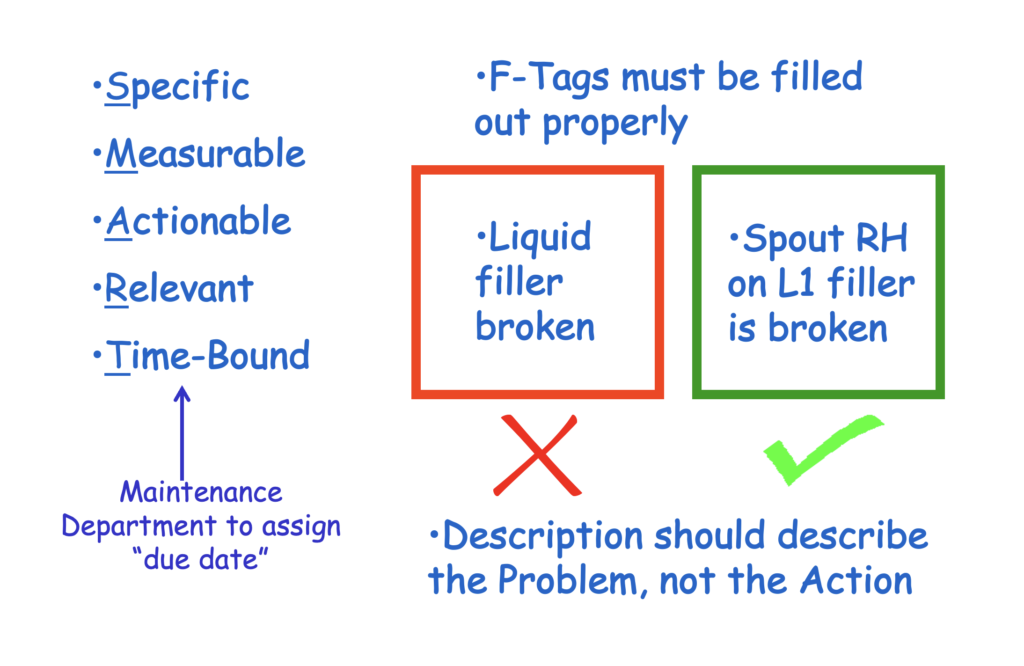

F-tags

Fuguai = Deviation

F-Tags are used to highlight Fuguais or Faults or Abnormalities:

- Functional Defects

- Pollution

- Difficult to Access/Observe

- Hard to Load/Operate

- Unsafe SHEQ “unfriendly”

- Undesirable Tasks

2 Major Types of F-Tags

- Operator

- Operator F-Tags are Blue

- Operator means anyone non-maintenance (ie. Operators, Utilities personnel, Supervisors, Cleaners, Sanitation, etc.)

- Maintenance

- Maintenance F-Tags are Red

- These F-Tags require Electricians, Mechanics, etc. to perform the task

The Colour of the Tag is for the person who will PERFORM the activity

Cleaning is Inspection

- Use your 5 senses:

- see –> use your eyes to observe

- hear –> listen and try to hear unusual noises

- smell –> try to discover strange smells

- touch and feel –> try to feel the heat, vibrations

- taste –> normally not suggested, but can be done from time to time

- Use your experience: think before you make a judgement

Where are Abnormalities Found?

- Main equipment:

- main parts

- operating system

- moving and turning parts

- transport systems

- hydraulic system

- compressed air system

- lubrication system

- cooling/heating system

- instrumentation

- Smaller parts

- nuts and bolts, screws

- chains, links

- pulleys

- springs

- cylinders

- piping and related parts

- valves, controls, filters

- couplings, bearings

- shaft, brakes

- Gaskets/seals

- switches, sensors

- cabling and related parts

- indicators, monitors, screens

- guards, doors, windows

- emergency switches, safety devices

Typical F-Tags

- Broken Parts Wear, Play, Rattling

- Dust, Dirt, Corrosion

- Cracks, Drip marks

- Deformation, Surface Damage

- Noisy, Hot, Cold, Odour, etc.

Use the SMART Principle

Use of Equipment Maps

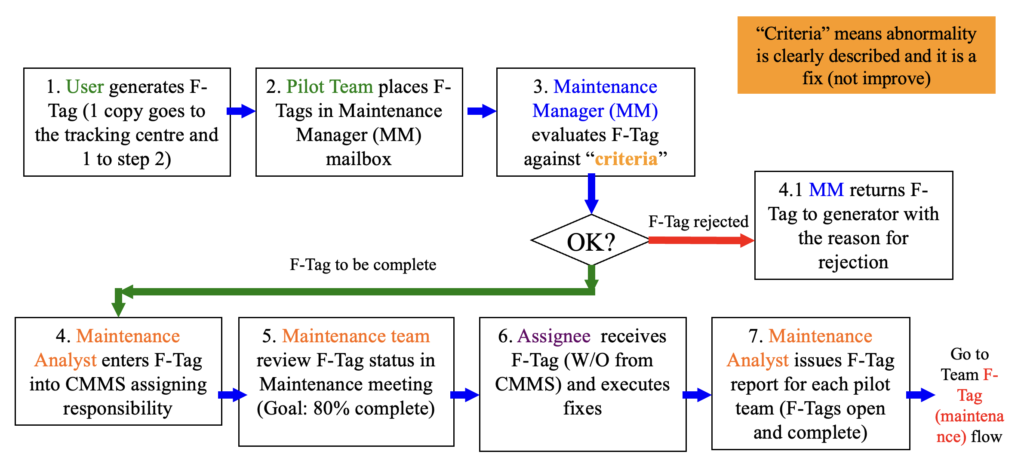

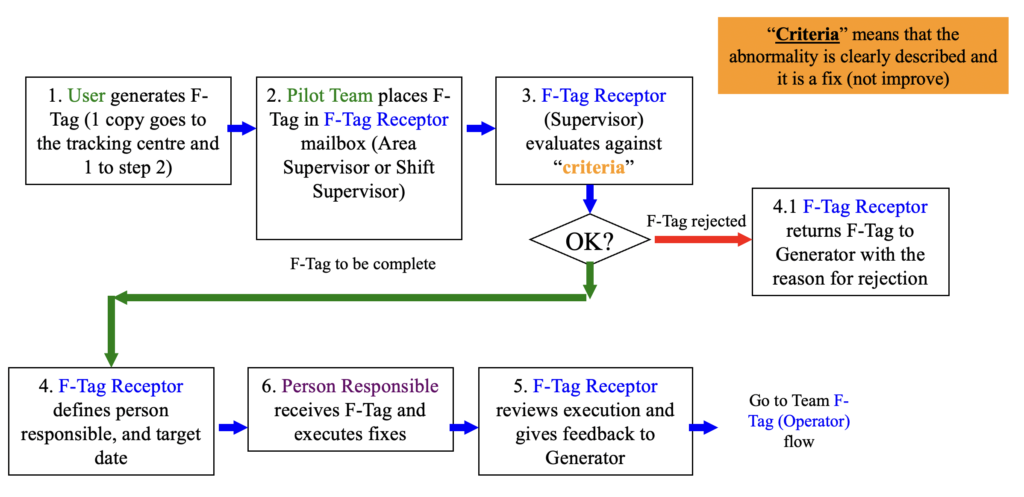

How to handle the flow of F-Tags

F-Tag (Operator) Flow

F-Tag (Maintenance) Flow