Focused Improvement

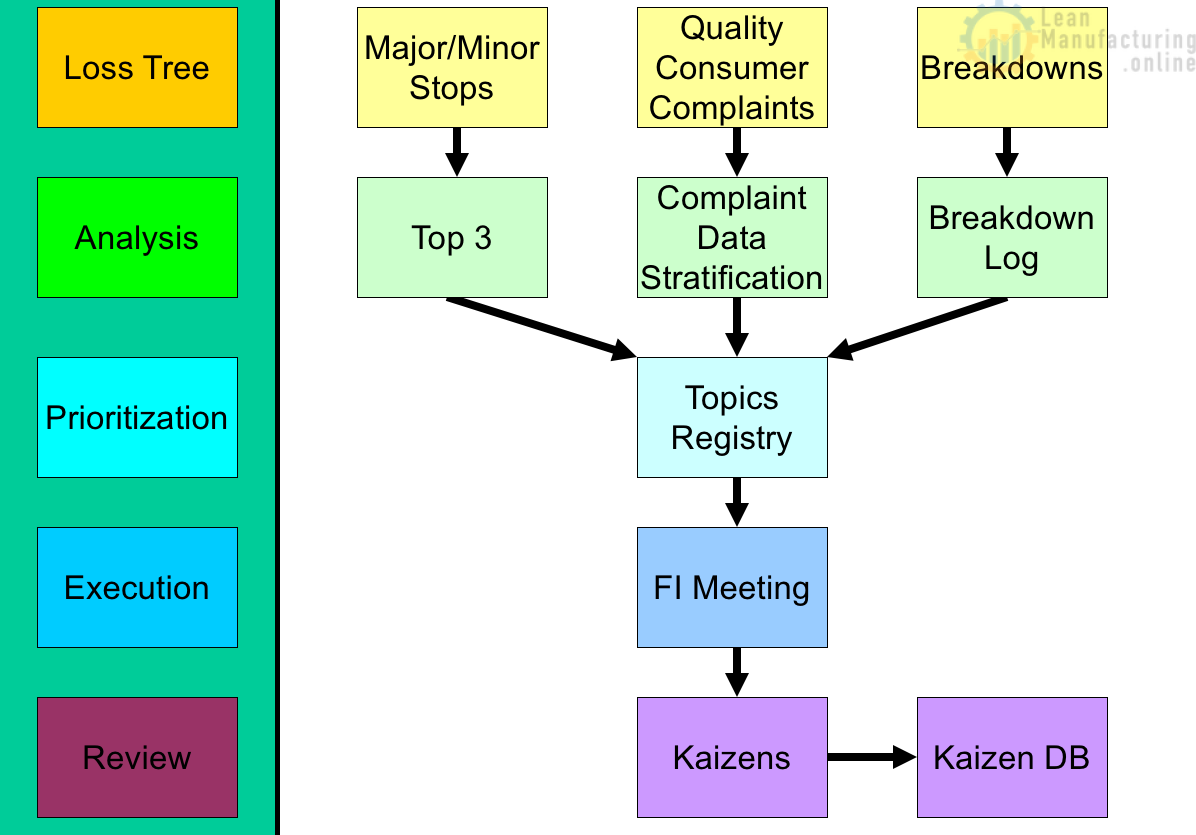

Focused Improvement Process

Focused Improvement Vision To eliminate all possible losses to improve safety and productivity, and reduce defects and production costs. To create a Continuous Improvement culture utilizing the Focused Improvement (Kaizen) technique to achieve maximum productivity of people, machinery, and material utilization, resulting in ZERO Accidents, ZERO Waste, ZERO Defects, ZERO…

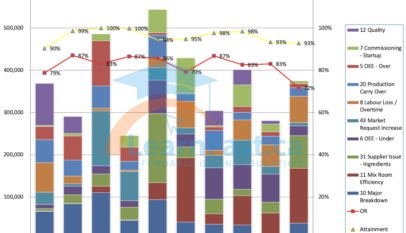

Read More »How Effectively Are Losses being Tackled? A 4-Level Assessment

A condition-based monitoring system has been established

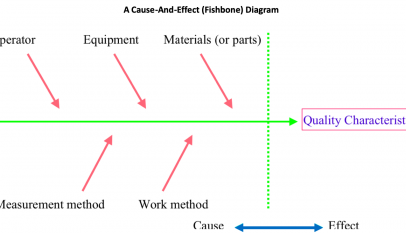

Read More »The 7 QC Tools

Exploring the 7 QC tools in lean manufacturing reveals a comprehensive set of strategies that enhance efficiency and minimize variability in production processes. The tools range from Cause-and-Effect diagrams, which focus on controlling processes, to Checksheets that streamline data collection, and Histograms that graphically represent data patterns. Pareto Diagrams prioritize…

Read More »Focused Improvement Project Selection Matrix

In the Selection Phase, potential projects are identified. Nominations can come from various sources, including associates and customers. To avoid sub-optimization, potential projects have to be evaluated in order to select the one(s) that is of significant importance to the organization and its performance. The organization’s Strategic Plan can provide…

Read More »