Focused Improvement

Focused Improvement – Strategies for Improving Changeover

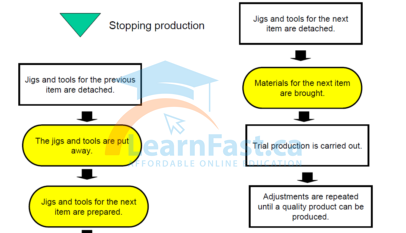

Although the time wasted on each occasion might be as short as one or two minutes, it is essential to eliminate these delays, because the total time lost can be very great.

Read More »Focused Improvement – Some Common Issues Associated with Changeover

This is why changeover times vary so widely and why, depending on the operator, problems may be experienced when production is started up, making it necessary to reset the machines

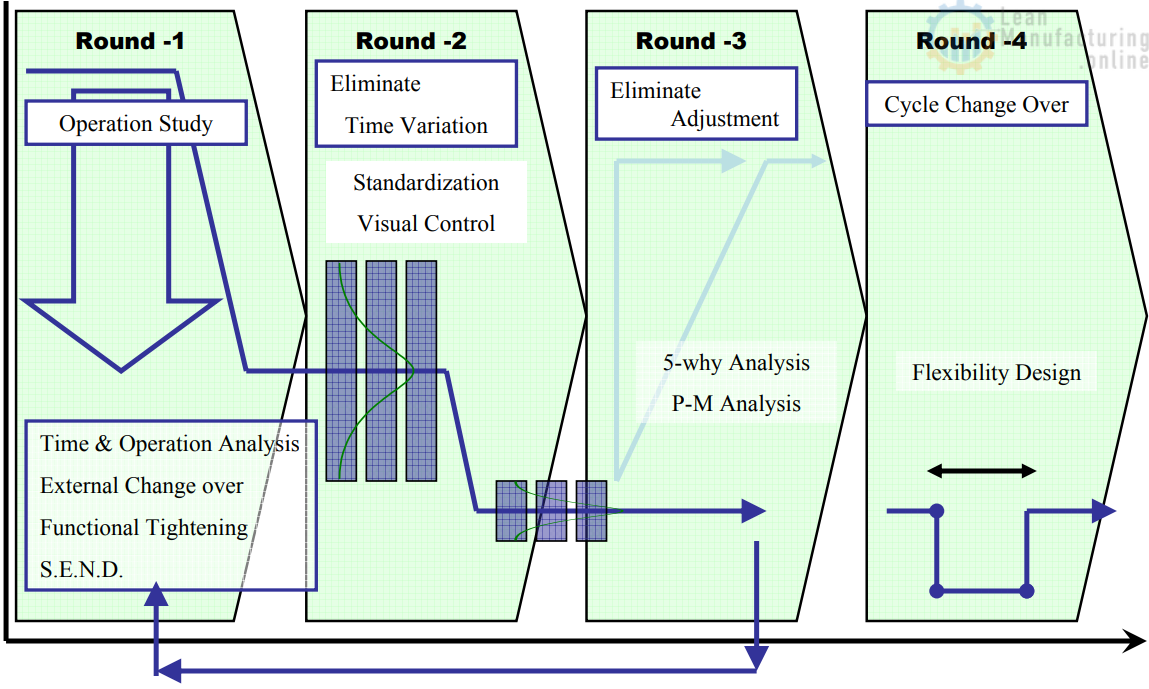

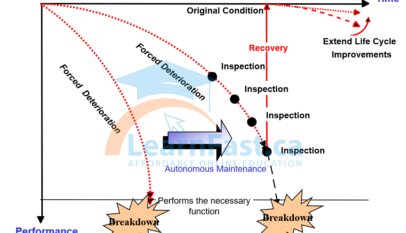

Read More »Focused Improvement – The 4 Phases to Zero Breakdowns

The 5 Zero-Breakdown Countermeasures will not work well if they are introduced in a rush or if more than one is implemented at a time. The best approach is to introduce them progressively in four phases. The main thrusts of the four phases, outlined in Table “The 4 Phases to…

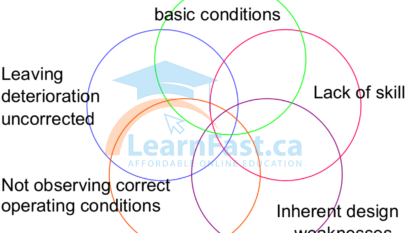

Read More »Focused Improvement – The 5 Main Factors that Cause Equipment to Fail, and the Priority Issues

The fastest way to achieve zero breakdowns is to implement all five countermeasures in order to identify and deal with every latent problem.

Read More »