TPM

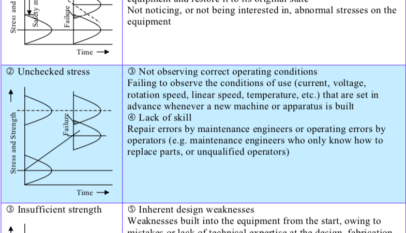

The Three Main Reasons Why Equipment Fails

Weaknesses built into the equipment from the start, owing to mistakes or lack of technical expertise at the design, fabrication or installation stages.

Read More »Planned Maintenance Indicators

(1) Failure Frequency “Failure frequency” denotes the incidence of failure as a percentage of loading time (the time during which the equipment is supposed to be operating). The “frequency” part of this term was borrowed from the discipline of safety management. The following formula expresses this index: (2) MTBF (Mean…

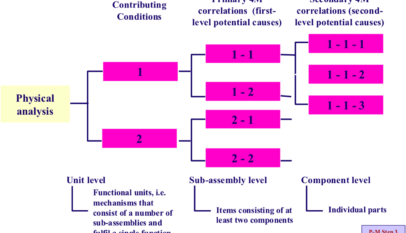

Read More »Focused Improvement – The Steps of P-M Analysis. Steps 5 – 8

Restoring something means getting it back into its original, correct condition.

Read More »Focused Improvement – The Steps of P-M Analysis. Steps 1 – 4

The broken surfaces should be examined under a magnifying glass or microscope to determine their condition and structure, and the part should be kept until the cause of the problem has been tracked down.

Read More »