TPM

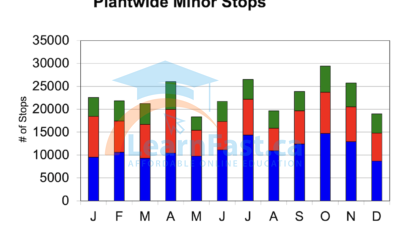

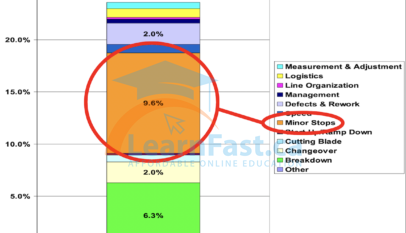

Focused Improvement – Strategies for Reducing Minor Stops

(1) Analyze phenomenon and workpiece behaviour Although the most important thing in reducing minor stops is to observe them actually happening, the opportunities for doing this are limited, making it difficult to devise precisely targeted remedial action. Phenomena should be videoed (using high-speed cameras for very fast minor stops) in…

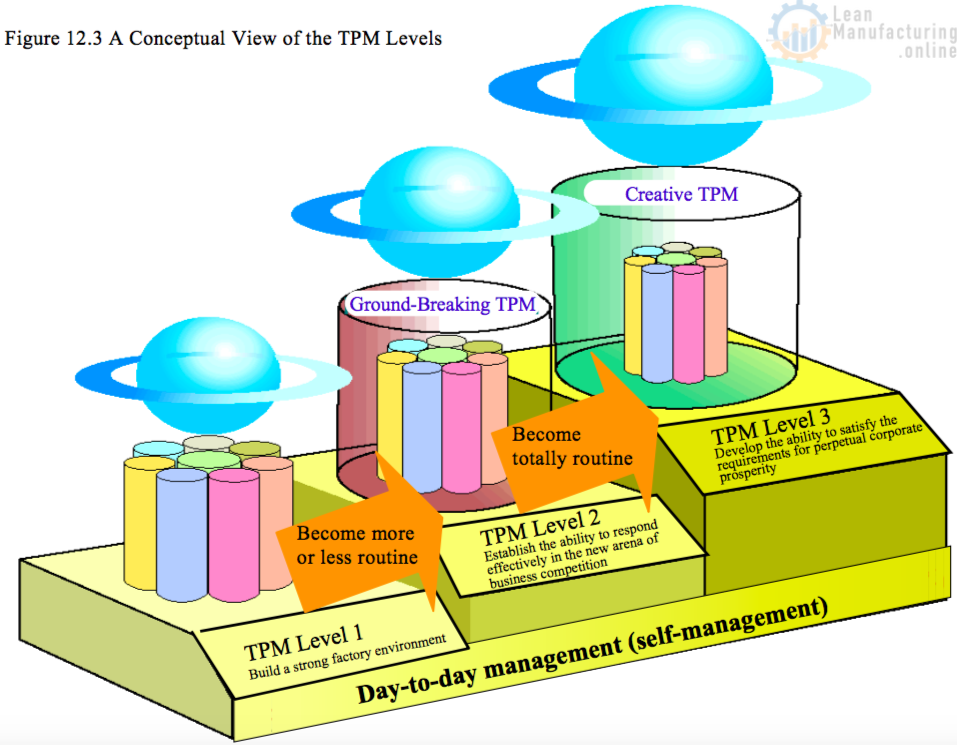

Read More »Chapter 12. Completing and Upgrading the TPM Programme (Levels 1, 2 and 3). Part 1

1 The New Concepts of TPM 1.1 The Basic Thinking behind the New Concepts of TPM When markets change, it means that social values themselves have changed, and this means manufacturing is required to: Cope with uncertainty in markets and demand, not certainty. Optimise business processes globally, not locally.Evaluate business…

Read More »Ensure that everyone is fully trained in TPM implementation and that the different departments are pulling together

Before embarking on the 7 Steps, everyone at every level, including managers from the top echelon right down to front-line supervisors, in all departments concerned, should be given comprehensive training in how the TPM program will be rolled out, and the activities involved. Departmental and area managers from the production…

Read More »Focused Improvement – Some Common Issues Associated with Minor Stops

(1) The losses remain hidden Minor stops may be simple and easily corrected, but the losses they generate are surprisingly large if their rate of occurrence is high or if it is a long time before they are noticed. They are often not treated as a serious problem because people…

Read More »