Instructor Training

Getting Ready for TPM

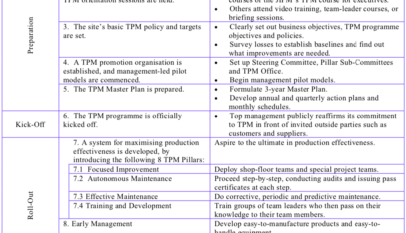

Introductory stage of TPM is vitally important - just as important, in fact, as the planning and design stages are to releasing a new product.

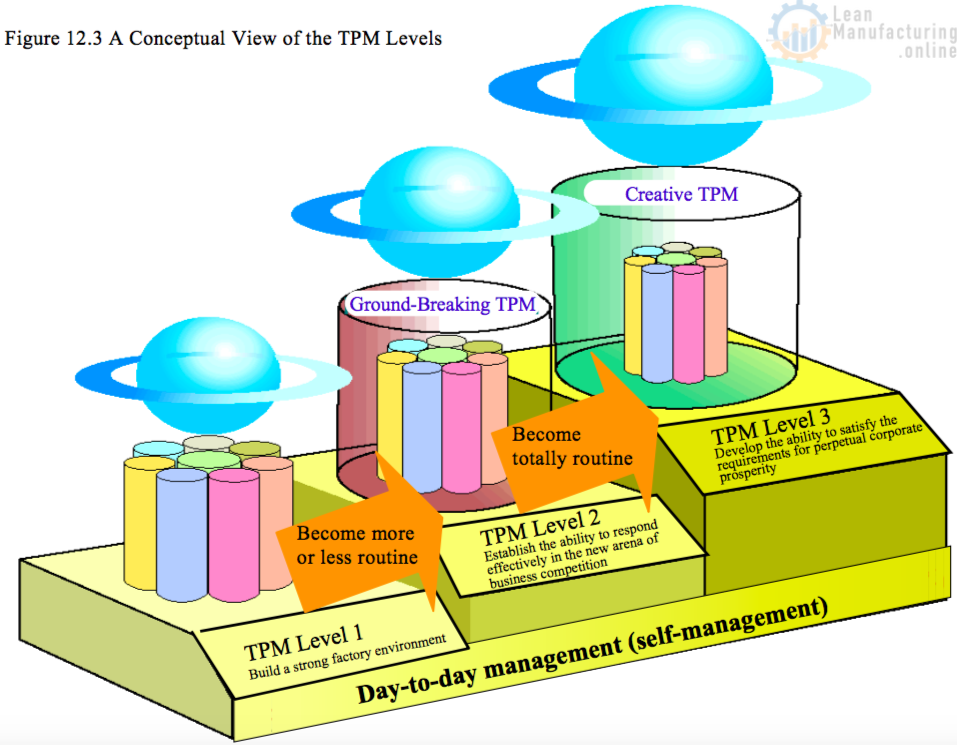

Read More »Chapter 12. Completing and Upgrading the TPM Programme (Levels 1, 2 and 3). Part 1

1 The New Concepts of TPM 1.1 The Basic Thinking behind the New Concepts of TPM When markets change, it means that social values themselves have changed, and this means manufacturing is required to: Cope with uncertainty in markets and demand, not certainty. Optimise business processes globally, not locally.Evaluate business…

Read More »TPM 3 Levels – path to World-Class Manufacturing

5S Autonomous Maintenance Blog Change Management Early Equipment Management Early Product Management Education and Training Focused Improvement Instructor Training Manufacturing Support Planned Maintenance Quality Safety, Health and Environment TPM TPM Introduction World Class Manufacturing

Getting to Level 3 of Total Productive Maintenance will require a LOT OF hard work, but it’s doable. Listed below is a 20-Step process on how to get there, steps 1-12 are part of Level 1 (Excellent Factory), steps 13-17 – Level 2 (Excellent Supply Chain) and finally, steps 18-20…

Read More »Chapter 6. Planned (Effective) Maintenance. Part 3

4.4 Standardization of Maintenance Activities 4.5 Creating and Managing Maintenance Budgets 4.6 Keeping and Using Maintenance Records 4.7 Main Activities in Building an Effective Maintenance System

Read More »