1 The New Concepts of TPM

1.1 The Basic Thinking behind the New Concepts of TPM

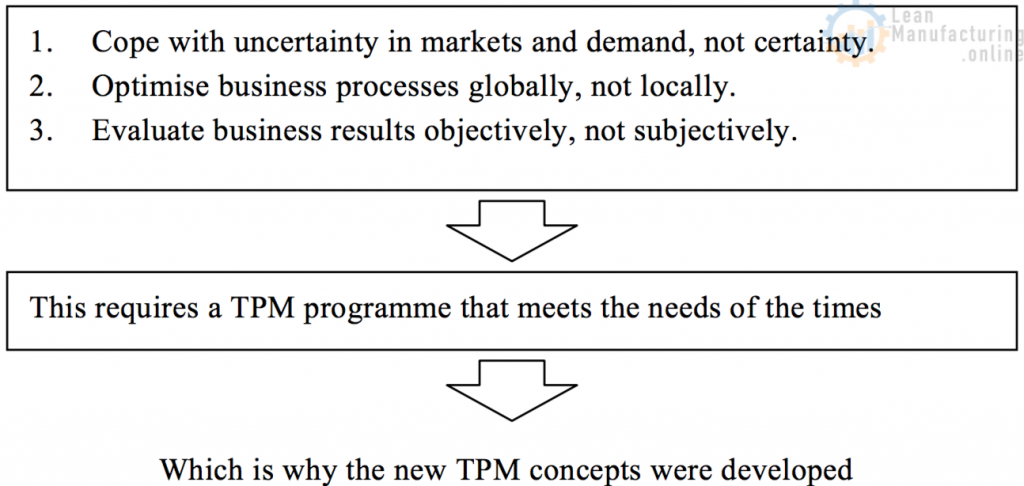

When markets change, it means that social values themselves have changed, and this means manufacturing is required to:

Cope with uncertainty in markets and demand, not certainty. Optimise business processes globally, not locally.

Evaluate business results objectively, not subjectively.

This chapter introduces the new concepts of TPM as a de-facto standard and profit-making tool, bearing these three requirements in mind.

A TPM programme is a means for companies to strengthen themselves and achieve their business objectives. Crudely put, it is a way of making more money. So, how exactly do we make more money? The answer is simple – by eliminating each and every factor that gets in the way of us making higher profits. In TPM, we call these factors ‘constraints’, and we believe that getting rid of them, or preventing them from arising in the first place, is the best way of making our businesses more profitable.

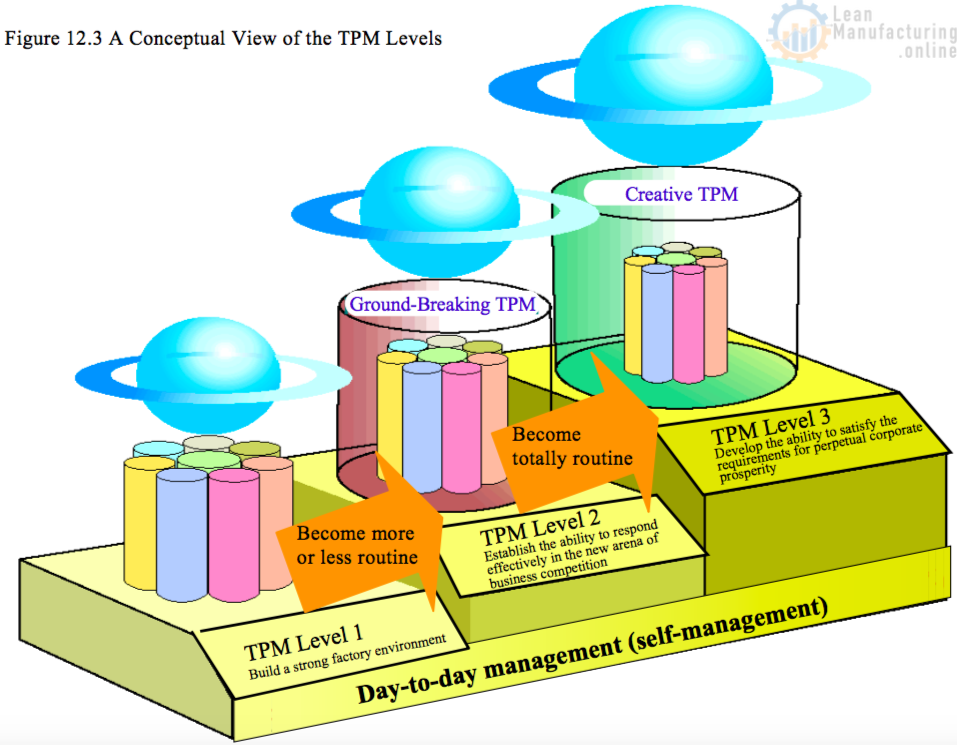

Having said that, it is impossible to do away with these constraints all at once. It is much more practical to proceed systematically, step by step, and the steps to be followed correspond exactly to the new concepts we are proposing at TPM Levels 1, 2 and 3. Figures 12.1 to 12.3 illustrate how the new concepts were developed.

Figure 12.1 The Key Things Manufacturing Must Now Do

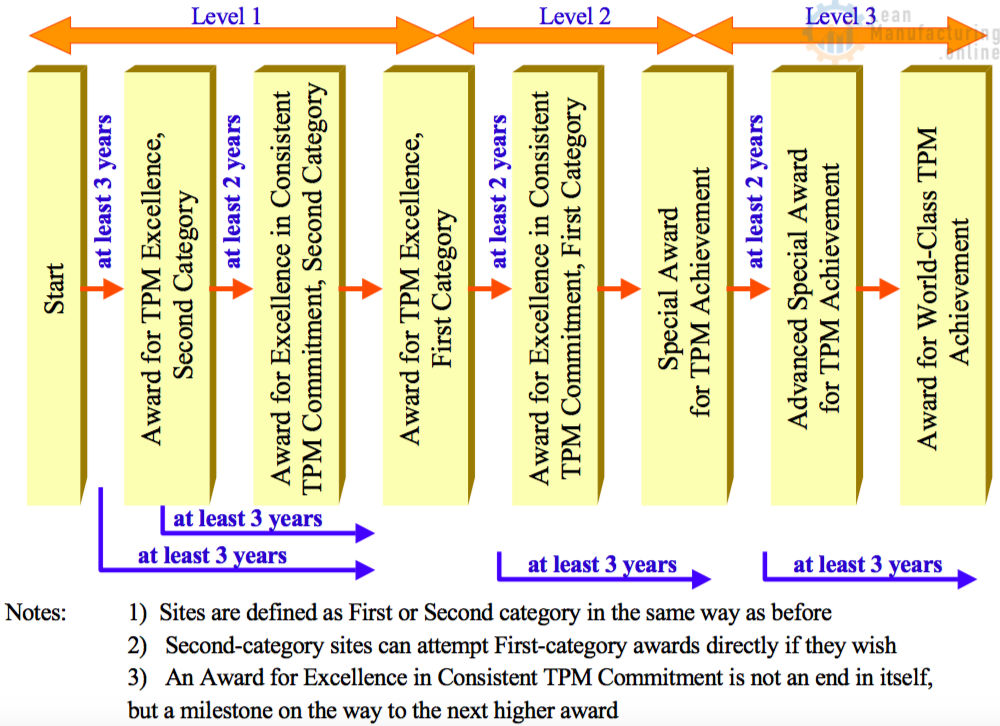

To begin with, the relationship between the three TPM levels and the various TPM awards was clarified:

As outlined in TPM Award by JIPM:

Plants/factories that have introduced TPM (Total Productive Maintenance – PM with participation by all members) and have shown significant achievement are eligible to apply. Please confirm that your plant meets the requirement before applying.

Eligibility for each category is as defined below.

1) Award for TPM Excellence, Category B

- Must have a minimum of 2 years or more of achievement activity after the introduction of TPM

- Must have deployed activity based on five pillars of TPM focusing on the production site (individual improvement; autonomous maintenance; planned maintenance; education and development; safety, sanitation and environment control).

- Must have completed Step 4 for autonomous maintenance activity.

- Must have completed infrastructure development for TPM activity with both tangible and intangible achievements obtained

2) Award for TPM Excellence, Category A

- Must have a minimum of 3 years or more of achievement activity after the introduction of TPM

- Must have deployed activity based on eight pillars of TPM by all staff members of the plants/factories (individual improvement; autonomous maintenance; planned maintenance; initial management; quality maintenance; administrative and supervisory department; education and development; safety, sanitation and environment control).

- Must have completed Step 4 for autonomous maintenance activity.

- Must have completed infrastructure development for TPM activity with tangible and intangible achievements obtained

3) Award for Excellence in Consistent TPM Commitment

- Must have received the Award for TPM Excellence (Category A or B)

- Must have approximately two years of achievement activity after receiving the Award for TPM Excellence

- Must have deployed activity based on eight pillars of TPM by all staff members of the plants/factories (individual improvement; autonomous maintenance; planned maintenance; initial management; quality maintenance; administrative and supervisory department; education and development; safety, sanitation and environment control).

- Must have maintained and enhanced the results achieved when the Award for TPM Excellence was received and have established measures for their maintenance and continuation.

4) Special Award for TPM Achievement

- Must have received the Award for Excellence in Consistent TPM Commitment

- Must have a minimum of 2 years or more of achievement activity after receiving the Award for Excellence in Consistent TPM Commitment

- Must have deployed activity based on eight pillars of TPM by all staff members of the plants/factories (individual improvement; autonomous maintenance; planned maintenance; initial management; quality maintenance; administrative and supervisory department; education and development; safety, sanitation and environment control).

- Must have maintained and enhanced the results achieved when the Award for Excellence in Consistent TPM Commitment was received and engaged in distinctive and revolutionary activities.

- An award for Excellence in Consistent TPM Commitment is required for the applicants who wish to apply for Special Award for TPM Achievement.

5) Advanced Special Award for TPM Achievement

- Must have received the Special Award for TPM Achievement

- Must have a minimum of 2 years or more of deployment activity based on eight pillars of TPM after receiving the Special Award for TPM Achievement and show significant improvement in results.

- Must be deploying TPM activities after establishing essential items and be showing results, e.g.:

- Management (production maintenance, quality maintenance, environment maintenance, cost reduction, etc.), SCM, Development (new products, new facilities, etc.), and other contents are independently determined in line with the business category of the eligible site.

6) Award for World-class TPM Achievement

- Must have a minimum of 2 years or more of deployment activity based on eight pillars of TPM after receiving the Special Award for TPM Achievement or the Advanced Special Award for TPM Achievement.

- Must have deployed distinctive and creative TPM activities and be showing results.

2 TPM Level 1

2.1 The Concept of TPM Level 1 – Reducing Production Cost

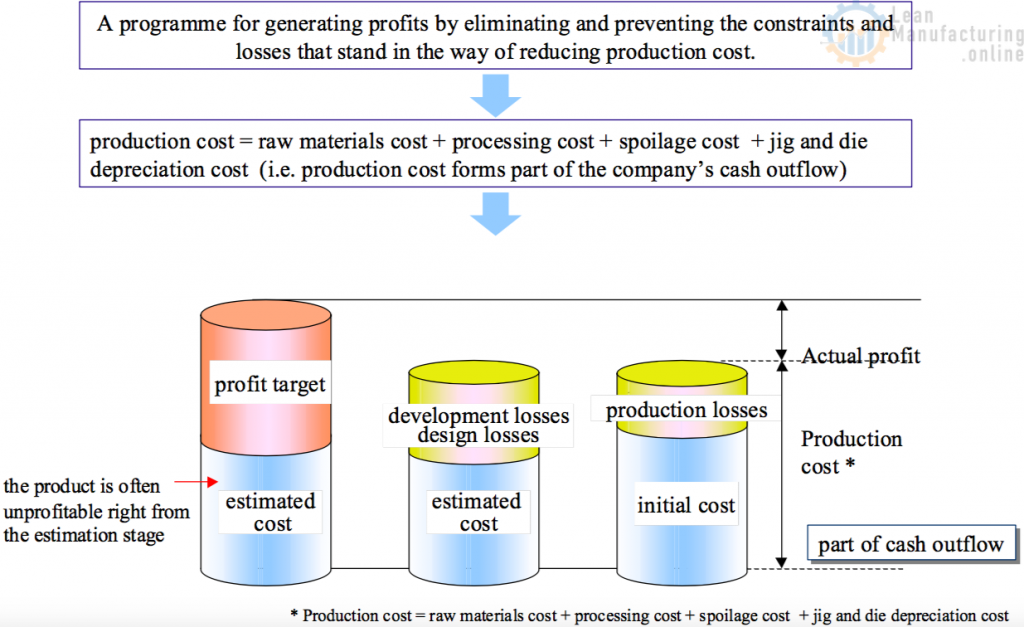

TPM has until now helped manufacturing sites around the world by focusing consistently on eliminating and preventing shop-floor losses. There is no change to this basic concept, which is applicable to any type of business environment. The issue is not the concept itself, but what it is applied to. In TPM Level 1, we concentrate on reducing production cost. We build highly profitable manufacturing facilities by strengthening the production floor and eliminating and preventing any factors standing in the way of reducing production cost, as defined by the following formula:

production cost =raw materials cost + processing cost + spoilage cost + jig and die depreciation cost

The factors standing in the way of reducing production cost, also known as ‘constraints’, exist in large numbers on any production floor and comprise losses such as the following:

- Losses reducing equipment performance

- Losses hampering the efficient utilisation of resources

- Organisational losses due to ineffective allocation of labour

- Losses due to high levels of work in progress

These are the losses we try to reduce in TPM Level 1. By working with the actual equipment and materials on the shop floor, we also try to build systems that will allow the equipment to perform to the levels we expect of it – and one of the principal aims of TPM Level 1 is to develop the abilities of operators, maintenance personnel, engineers, supervisors and managers through this process. Figure 12.4 lists the four key points of the activity at this level.

Figure 12.4 The 4 Key Points of TPM Level 1

The target — reduce production cost

- Equip the production floor with the basic capabilities it needs to make a positive contribution to business results.

- Strengthen the production floor’s QCD performance.

- Improve the company’s ability to manage the development of new products and equipment.

- Create safe, pleasant working environments.

2.2 The Scope of TPM Level 1

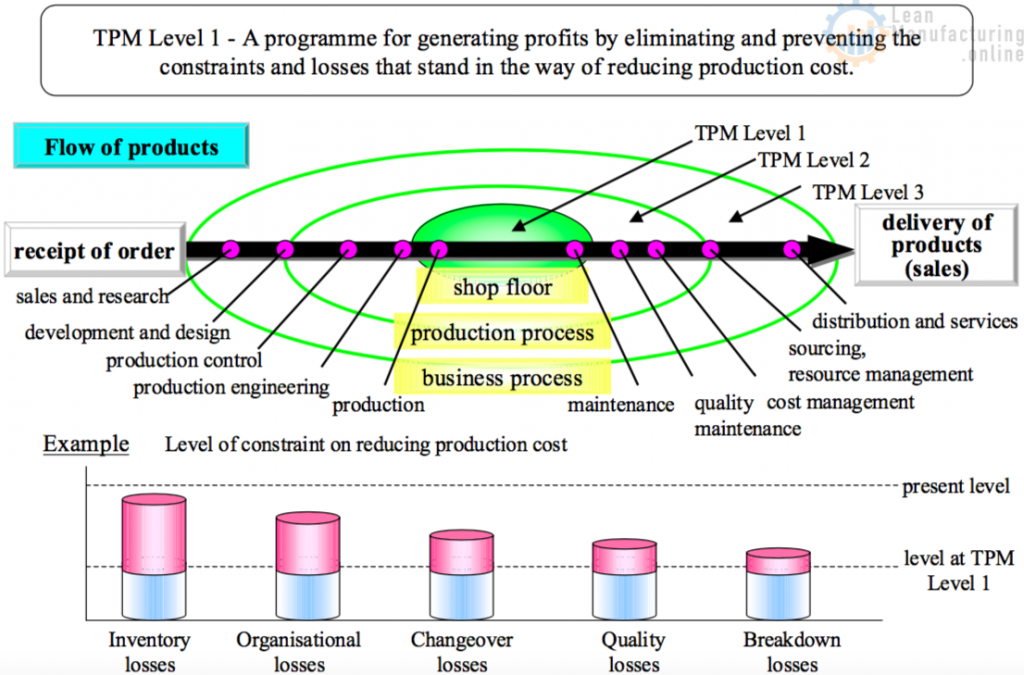

As Figure 12.5 shows, the production floor itself is the main focus of the TPM programme at Level 1.

2.2.1 The concept and aims of TPM Level 1

Concept: A programme for generating profits by eliminating and preventing the constraints and losses that stand in the way of reducing production cost.

In TPM Level 1, we aim to create a strong production floor that can generate a high level of profits by reducing production cost (see Figure 12.5). TPM Level 1 is positioned as a programme for generating profits by eliminating and preventing the constraints and losses that stand in the way of reducing production cost.

Any production operation conceals large numbers of losses, such as equipment breakdown losses (preventing equipment from performing as well as it should), changeover losses, quality and yield losses that hamper the efficient utilisation of raw materials, work organisation losses due to poor allocation of labour resources, and losses due to work-in-progress inventories created because of unbalanced process capabilities, poor synchronisation, and so forth. In TPM Level 1, the idea is to focus on these losses and reduce production cost by eliminating and preventing them, thereby generating more profits.

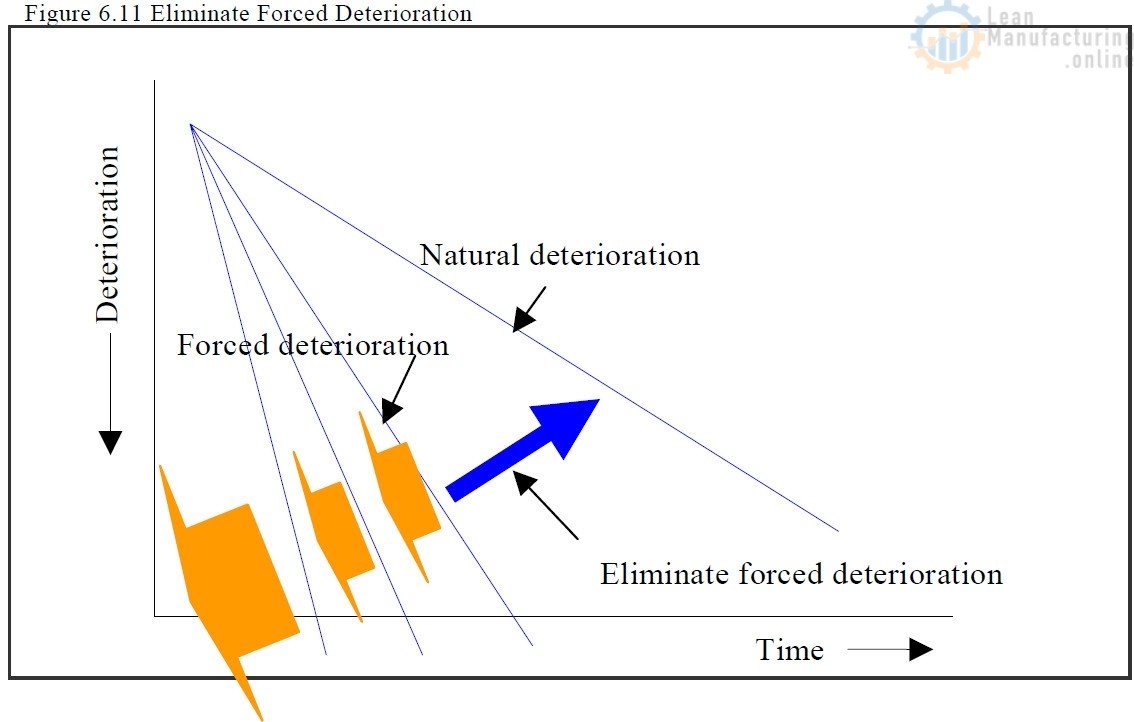

However, TPM Level 1 does not focus exclusively on reducing production cost. Another important aim of the programme is to concentrate on the equipment, using the hands-on approach to make it perform as well as we would like it to. Product output and quality depend entirely on the state of the equipment. When all is said and done, the production equipment is where the rubber hits the road as far as manufacturing is concerned. The degree to which equipment deterioration is left unchecked reflects the quality of the work done by the people responsible for managing and maintaining the machines. Controlling equipment deterioration (i.e. controlling the causes of breakdowns and quality failures), enables us to build a system that will allow the equipment to work as effectively as we would like it to. We are actually trying to build a system of health management for our equipment – and a further aim of TPM Level 1 is to develop the abilities of operators, maintenance personnel, engineers, managers and supervisors through the process of building such a system.

2.3 The Challenges of TPM Level 1

Figure 12.6 The Challenges of TPM Level 1

A summary of TPM Level 1

As already stated, the concept of TPM Level 1, the stage at which companies strive

to achieve the Award for TPM Excellence, is to ‘generate profits by eliminating and preventing the constraints and losses that stand in the way of reducing production cost’, as defined by the following formula:

production cost =

raw materials cost + processing cost + spoilage cost + jig and die depreciation cost

In other words, production cost constitutes part of the company’s cash outflow (sometimes called ‘production outflow’). The challenge set by the Award for TPM Excellence is to generate profits by eliminating and preventing constraints on reducing the various elements that make up the production cost (see Figure 12.6). To achieve this, the company’s production departments, technical departments and administrative departments must all work together as a team.

3 TPM Level 2

3.1 The Concept of TPM Level 2 – Reducing Total Product Cost

The principal aim of TPM Level 2 is to reduce total product cost. By doing this, we try to create a highly-profitable production and business operation and give ourselves a competitive edge over rival companies in our industry. Total product cost includes all forms of cash outflow (money leaving the business) and is equal to the production cost mentioned before, plus energy cost, distribution cost, development cost, sales cost, general administrative expenses and so on. In TPM Level 2, as well as continuing the activities we started during TPM Level 1, we strive to eliminate all other kinds of losses inherent in the management of our production operation, e.g.:

Lost opportunities and finished-product inventory losses due to poor coordination between sales and production.

Losses due to failure to achieve new-product target costs, emanating from the design and development departments.

Losses due to over-buying or failure to achieve target purchasing costs by the purchasing department.

We also do focused improvements during the development of improved models of existing products with the aim of preventing quality and yield losses and obviating the need for extra process installation work. And, in addition to eliminating existing losses and preventing new ones, we try to increase the added value of our products by upgrading their functionality, applicability and quality. In this way, we bolster our company’s competitiveness by including in our TPM programme focused-improvement activities designed to increase added value.

Manufacturing companies no longer have the luxury of being able to sell whatever they make. Now, they must make only what they can sell. To deal effectively with a paradigm shift like this, all of a company’s business processes must be organically interlinked. Naturally, this requires the active participation not just of the production floor but of all relevant departments including sales, development, distribution and administration. A company can only build a fast-acting manufacturing business structure that stands out from those of its competitors by developing globally-optimised, globally- integrated business processes that allow it to develop and make exactly the right products at exactly the right times in exactly the right quantities. While continuing to maximise the productivity of their production operations, companies now also need to maximise the productivity of their total business operations. This means that they are likely to develop highly-individual programmes designed to suit the particular business environments in which they and their manufacturing sites operate. Nevertheless, whatever the nature of a particular programme, the four key points remain constant:

The 4 Key Points of TPM Level 2

The target — reduce total product cost

- Establish systems for further strengthening and enhancing the basic capabilities of the production floor.

- Establish QCD in development, production and marketing.

- Carry out focused improvements designed to increase added value.

- Implement environmental conservation programmes.

A further important aim of TPM at Level 2 is to acquire, through the process of reducing total product cost, an all-round ability to respond to changes in the business environment.

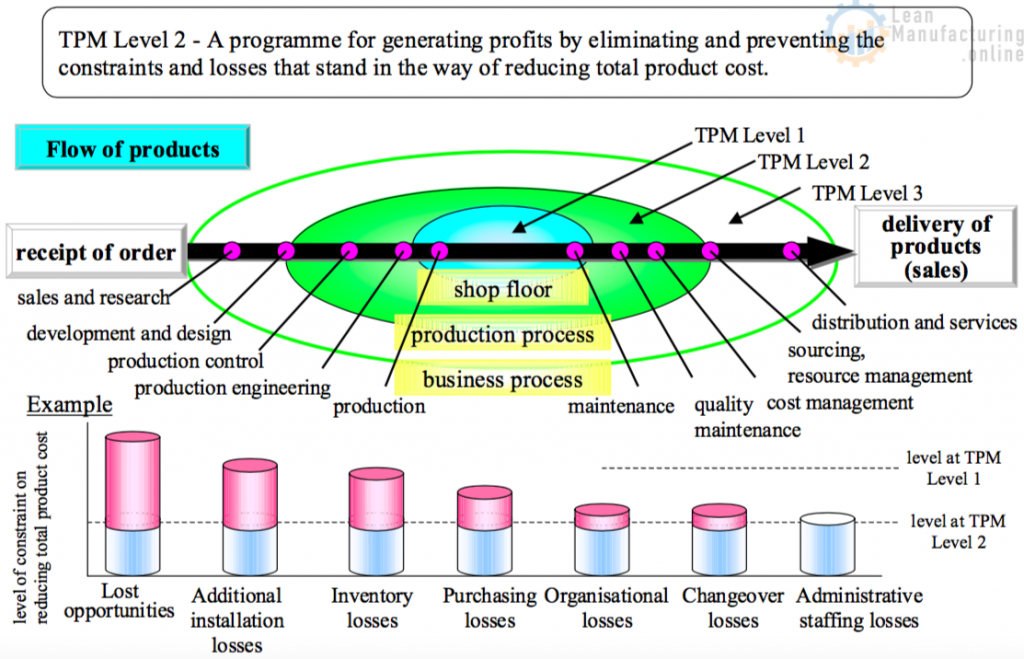

3.2 The Scope of TPM Level 2

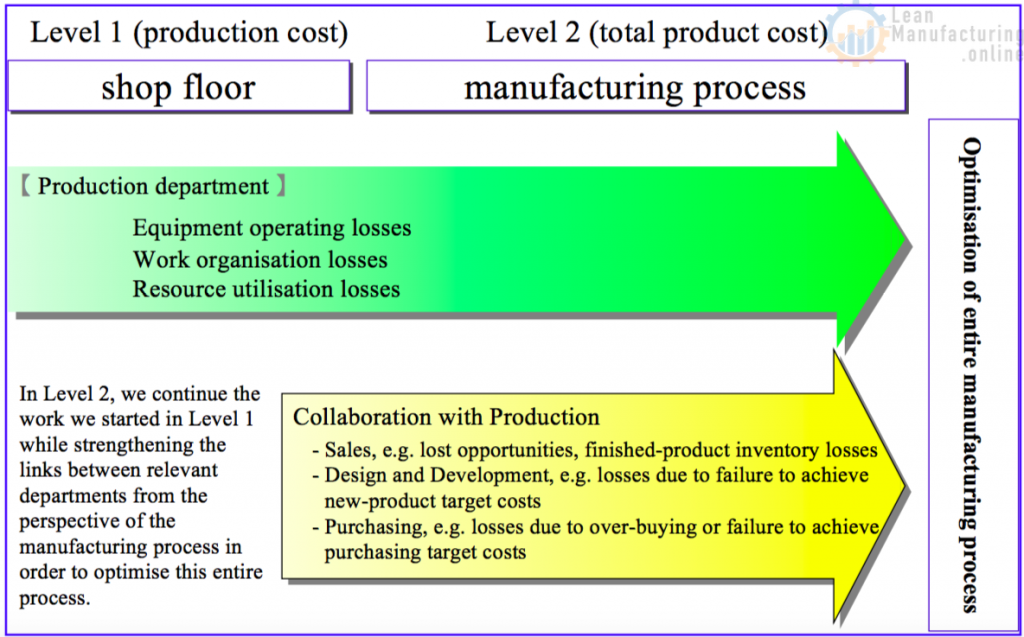

As Figure 12.7 shows, the scope of application of TPM at Level 2 is expanded from the production floor to include all relevant manufacturing processes.

Figure 12.7 The Scope of TPM Level 2

The concept and aims of TPM Level 2

Concept: A programme for generating profits by creating competitive products, developing the ability to respond to change, and eliminating and preventing the constraints and losses that stand in the way of reducing total product cost.

At TPM Level 2, companies should continue the work on eliminating equipment operation losses, work organisation losses and resource utilisation losses they started in Level 1. At the same time, they should extend their activities to target other losses, particularly lost business opportunities and finished-product inventory losses due to poor coordination between sales and production, losses due to failure to achieve new-product target costs emanating from the development and design departments (e.g. extra installation work or the introduction of additional production processes), and losses due to over-buying or failure to achieve purchasing target costs by the purchasing department.

Total product cost can be lowered, competitive products can be developed, and systems capable of responding to change can be constructed if all the relevant

departments within the production management process (from design and development through sales and purchasing to production) help to eliminate and prevent the types of losses listed above. This is the thinking behind TPM Level 2, as illustrated in Figure 12.7.

The activity of reducing total product cost should not be restricted to existing products; it should also be applied to improved models of existing products, the development of which should be handled as focused improvements for increasing added value. Preventing quality and yield losses and obviating the need for extra process installation work, while increasing the added value of products by upgrading their functionality, applicability and quality at the development stage, is exactly what must be done in order to establish the ability to respond effectively in the new arena of business competition.

A further point worth underlining is that the aim of TPM Level 2 is not just to reduce total product cost in order to improve profitability, but also to develop the capacity to respond to changes in the business environment in cost-competitive markets through the process of reducing those costs. There is a limit to what the shop floor can do in terms of responding to market change. Total reliance on the shop floor may have worked in the days when companies could sell whatever they made, but we must move with the times; now, we must make only what we can sell. We will be unable to deal adequately with change in the midst of a paradigm shift like this unless our business processes are interlinked organically and responsively. We can only build a fast-acting manufacturing business structure that stands out from those of our competitors in the midst of today’s rapid changes in market competition by developing globally-optimised, globally- integrated business processes that coordinate the activities of all of departments including sales, development, production and administration. This is one of the major aims of TPM

3.3 What Should be Achieved during TPM Level 2 (1)

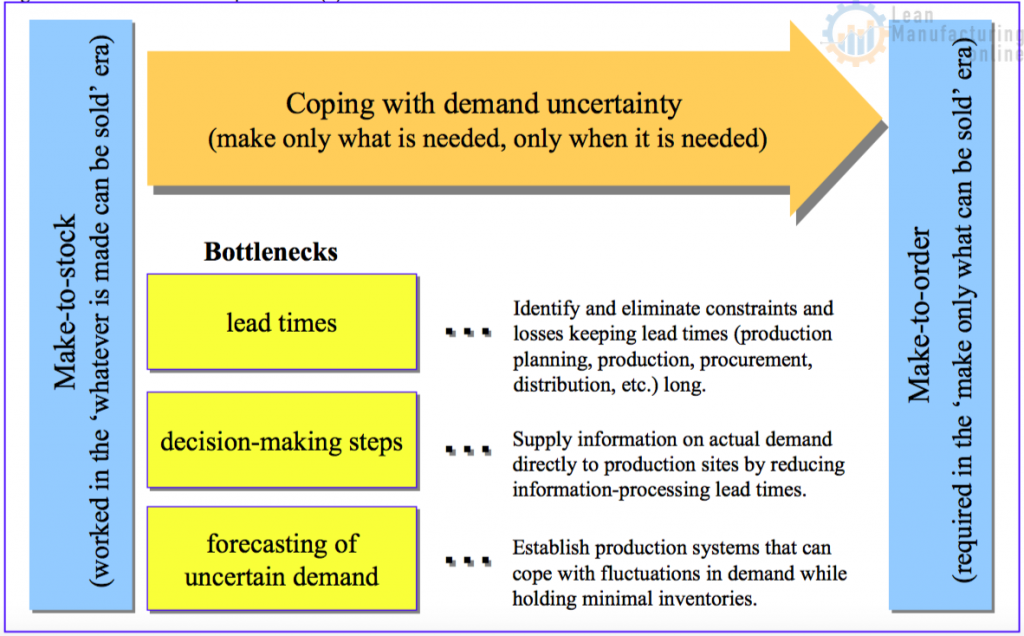

Figure 12.8 illustrates some of the things a company must achieve as it moves up from TPM Level 1 to TPM Level 2.

Figure 12.8 TPM Level 2 requirements (1)

3.4 What Should be Achieved during TPM Level 2 (2)

Figure 12.9 illustrates some other things a company must achieve as it moves up from TPM Level 1 to TPM Level 2.

3.5 The Challenges of TPM Level 2

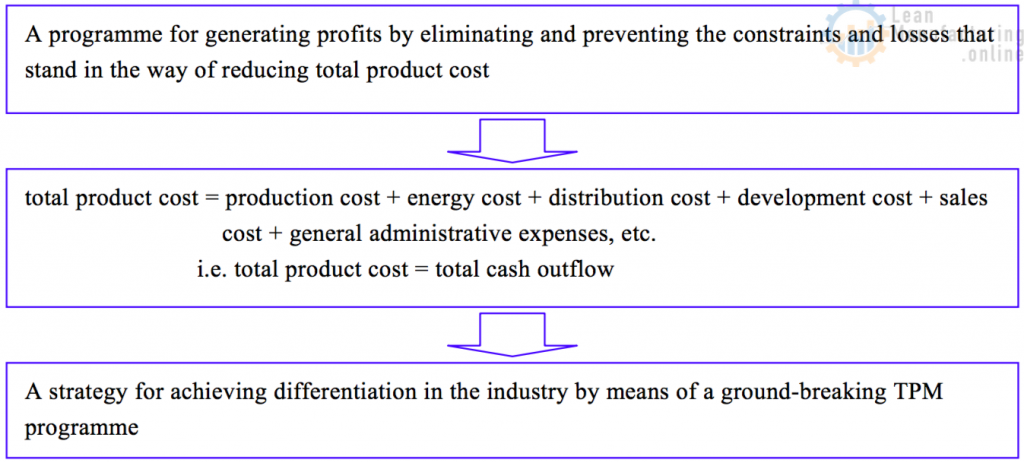

3.5.1 A summary of TPM Level 2

As already stated, the concept of TPM Level 2, the stage at which companies strive to achieve the Special Award for TPM Achievement, is to ‘generate profits by eliminating and preventing the constraints and losses that stand in the way of reducing total product cost’, where total product cost is defined by the following formula and is equal to the total amount of cash leaving the business:

Total product cost = production cost + energy cost + distribution cost + development cost + sales cost + general administrative expenses, etc.

Eliminating and preventing constraints on reducing the losses within the various elements that make up the production cost naturally requires the active participation not just of the production, production engineering and maintenance departments but of all other relevant departments including sales, development, distribution and administration.

Another component of the Special Award for TPM Achievement challenge is the need for companies to ‘establish the ability to respond effectively in the new arena of business competition’, which means responding to the paradigm shift mentioned earlier (the transition from ‘whatever is made can be sold’ to ‘make only what can be sold’). The ‘new arena of business competition’ is the time in which we now live, when we must make no more nor less than what we can sell, and this requires programmes that will allow our companies to remain profitable by establishing the ability to respond effectively in the current business environment. Although the essence of TPM has not changed, and it still has production equipment at its core, we now require TPM programmes capable of adapting to changes in the market environment. We must expand the scope of our TPM programmes and secure the active participation of every department involved with the production system in any way, including sales, development, purchasing, production, distribution and administration – which is how it becomes possible to make only what is needed only when it is needed and to construct a production system that does not develop or produce anything that cannot be sold. As a result, the productivity of the entire business operation, not just the production part of it, rises (see Figures 12.8 and 12.9), and the company becomes able to differentiate itself from its competitors and gain an advantage in its industry.

The shift from the productivity of production to the productivity of the entire business operation is a shift from measuring productivity from the perspective of ‘making’ to measuring productivity from the perspective of ‘responding’. To increase the productivity of the business, we must eliminate and prevent losses and constraints standing in the way of reducing total product cost. We must also build development and production systems designed to produce only what is needed when it is needed in order to differentiate ourselves from our competitors and survive and prosper in our industry.

This is TPM Level 2’s biggest challenge.

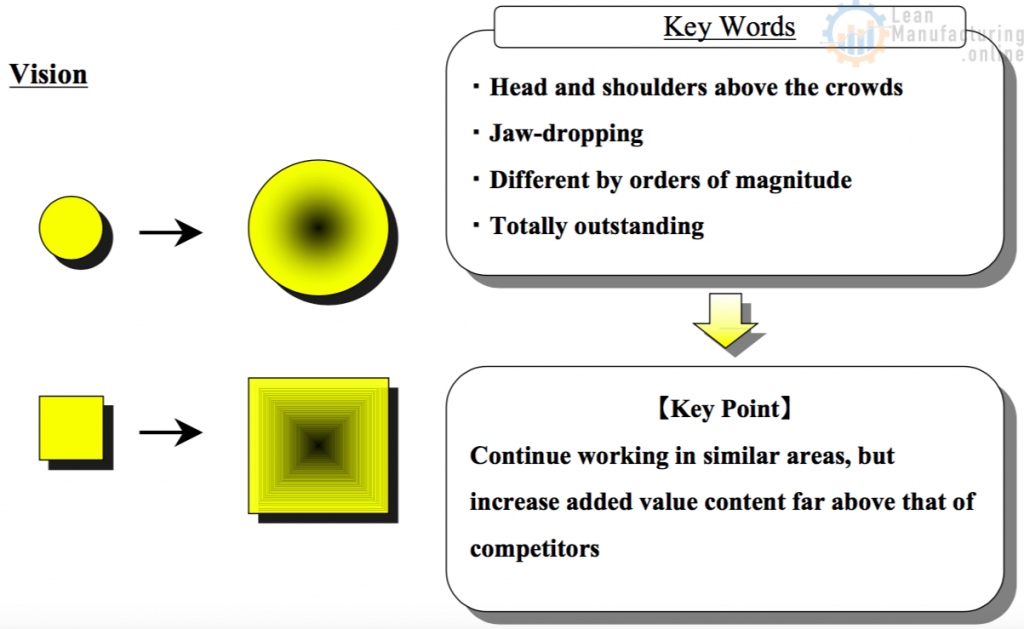

This means that, from TPM Level 2 onwards, companies and production sites should be pursuing TPM programmes with a high level of originality – programmes whose essence is encapsulated in the phrase ‘Ground-Breaking TPM’ (see Figure 12.11).

Figure 12.11 Ground-Breaking TPM

What is meant by ‘Ground-Breaking TPM’?

Figure 12.12 From Productivity of Production to Productivity of Business

Productivity of production = (amount produced / amount input) x 100

Productivity of business = (amount sold / amount input) x 100

To keep on winning instead of merely surviving, companies need to establish something ‘head and shoulders above the crowd’ or ‘different by orders of magnitude’ within their production systems, as compared with the competition. This is what ‘ground-breaking’ means; in business terms, it has the characteristic of a strategy of differentiation; for example, it might mean making a product ten times cheaper than any rival product, or with eye-poppingly high quality or performance, or with delivery lead times an order of magnitude shorter. Ground-breaking features like this should be indispensable parts of a company’s or factory’s strategy for differentiating itself within its industry and annihilating the competition.