TPM

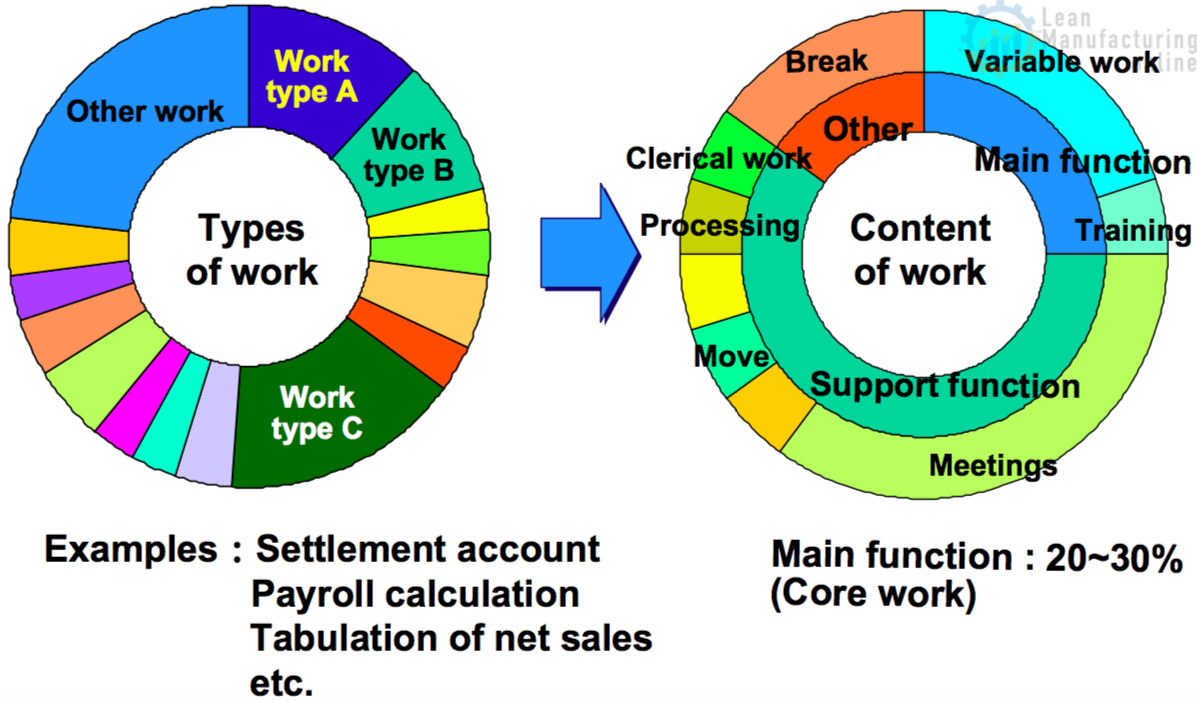

Strengthening of Administrative Division Functions through MAKIGAMI Analysis. Part 1

MAKIGAMI analysis achieves greater operating efficiency not merely by reducing the eight major losses in administrative work, but by contributing significantly and positively to management.

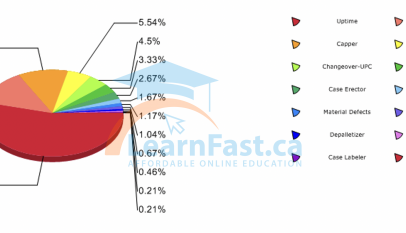

Read More »Focused Improvement Pillar OEE Losses Definition

Problems in the Current Process Too many people and systems manipulate the informationAll unaccounted downtime is charged to minor stopsDowntime Losses + OEE hardly close to 100%Open spreadsheet to calculate OEEConcepts are not well understood by those entering the informationAdjustments in the OEE Losses Tree are made at the end…

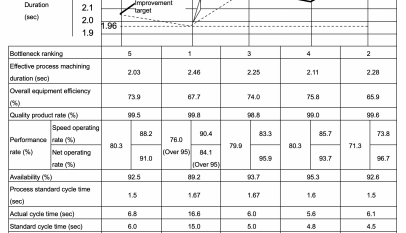

Read More »Overall Equipment Efficiency and Effective Process Duration Calculations Sheet

If, A: Actual working time of one shift = B: Scheduled down time of one shift = C: Loading time of one shift = A-B = D: Stoppage loss time of one shift = E: Operating time of one shift = C-D= G: Number of units processed in one shift…

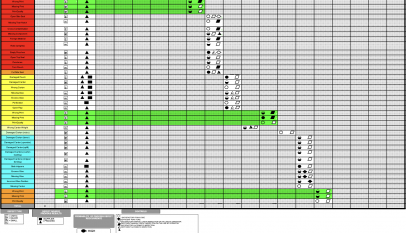

Read More »QA Matrix

Quality Assurance Matrix (QA Matrix) A QA matrix is a table that delineates how defects are being built into products under current conditions, in a process in which one wishes to assure quality. This matrix enables managers to see at a glance which processes are generating defects, which processes’ equipment…

Read More »