TPM

Boost Your Preventive Maintenance Performance with a Targeted Gap Analysis

Unleash the full potential of your preventive maintenance program by conducting a targeted gap analysis. This powerful tool evaluates your current maintenance approach, identifies areas of inefficiency, and helps prioritize improvements for maximum effectiveness. Discover the key steps to implementing a successful gap analysis, from defining the scope to developing…

Read More »Quality. Project-by-project improvement

Project-by-project improvement is a highly effective way to achieve quality improvement because it allows teams to focus on specific areas of improvement, and then apply the appropriate resources and strategies to achieve measurable results. By focusing on individual projects, teams can quickly identify and implement improvements, and then use those…

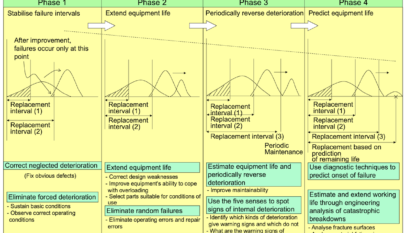

Read More »World-Class Maintenance. Switching from firefighting mode to planned system

World-class maintenance is a proactive approach to equipment maintenance that emphasizes prevention, planning, and continuous improvement. It requires a shift from a reactive, firefighting mode to a planned system that anticipates and addresses maintenance needs before they become critical. This shift in mindset and approach can help organizations reduce downtime…

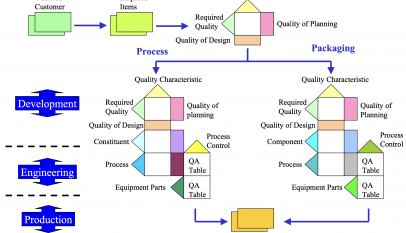

Read More »Supplier Quality Management

Improve your supply chain and increase your operational efficiency with effective Supplier Quality Management. Learn how to assess and select the right suppliers, establish quality requirements, perform audits and inspections, manage nonconformances, and measure performance. With these strategies, you can reduce costs, improve delivery times, enhance customer satisfaction, and boost…

Read More »