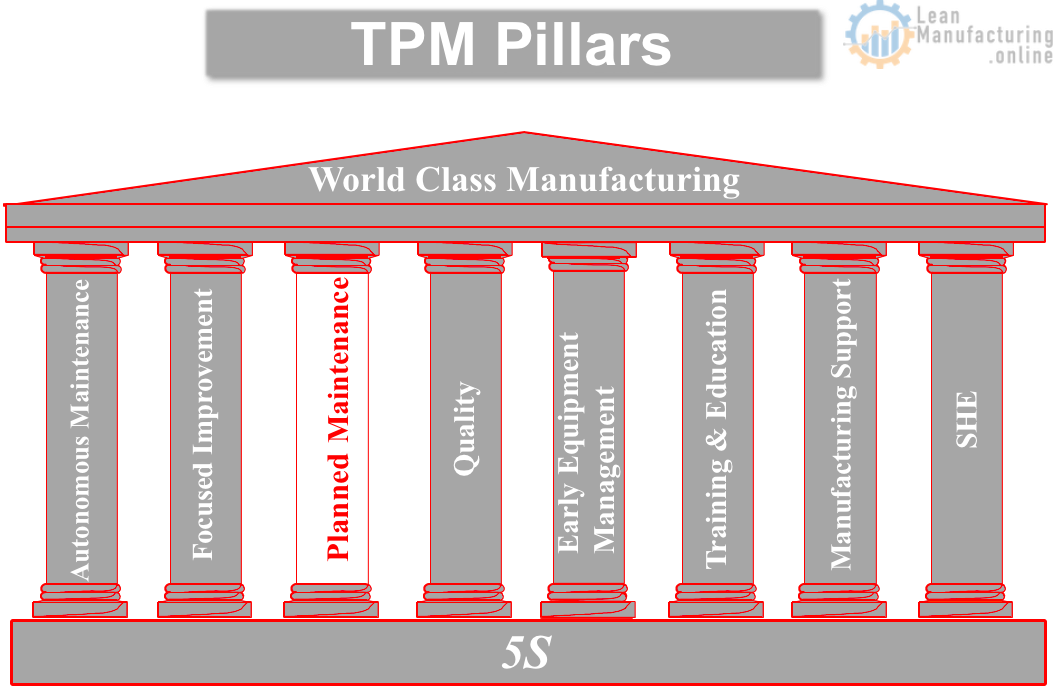

Planned Maintenance

Key Recommendations for PM improvements – Case Study

The most important skill required of an operator is the ability to identify abnormalities and notice immediately when something is not quite right with the output quality or the equipment.

Read More »Breakdown analysis. Case Study

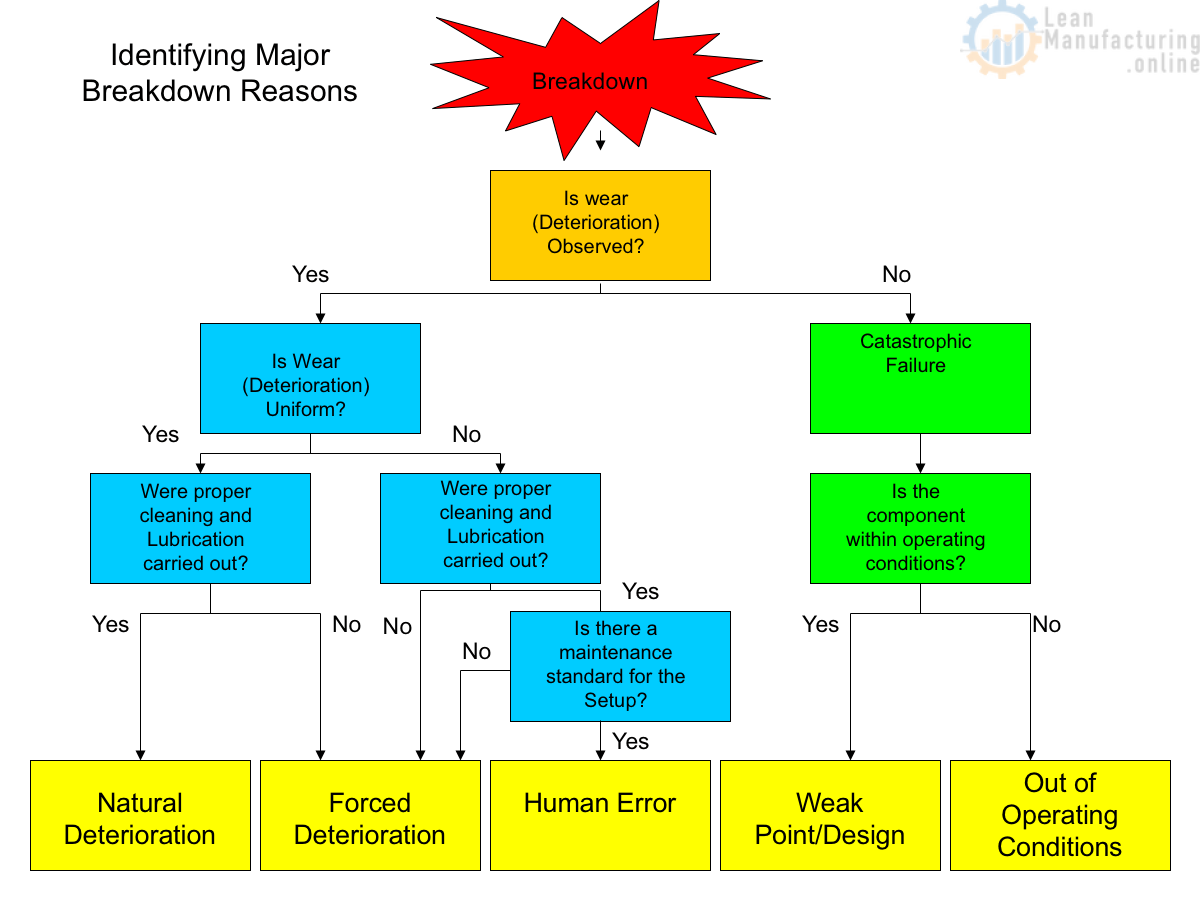

Let’s review an example of Breakdown Analysis of the failure that occurred in real life in the material handling department of a manufacturing factory: Step 1. 5W+1H and Phenomenon Summary Start your Breakdown analysis by answering six simple questions: 5 whys and 1 how Phenomenon Summary Use all answers from…

Read More »What is a Breakdown?

The word “Breakdown” seems to be self-explanatory. Webster’s definition of a breakdown is:“ A failure to function, a function loss, failure to progress or have an effect”. When we apply it to equipment or assets, then anytime the equipment or asset fails to perform when required at design capacity and…

Read More »Working on or near live electrical equipment parts

This Guidance Document describes rules and procedures for safe working with high voltage electrical equipment. It details operating procedures, Permit to Work and other safety documents, provisions for entry into High Voltage enclosures, safety precautions prior to working on conductors and tests required on equipment. SCOPE It is recommended that…

Read More »