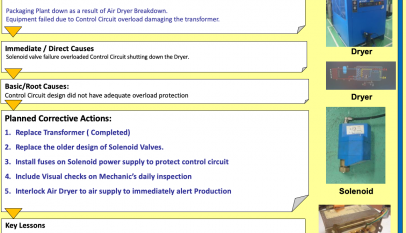

Let’s review an example of Breakdown Analysis of the failure that occurred in real life in the material handling department of a manufacturing factory:

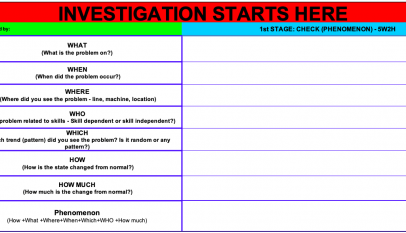

Step 1. 5W+1H and Phenomenon Summary

Start your Breakdown analysis by answering six simple questions: 5 whys and 1 how

5W+1H

Description

Example

What

What happened? What is the problem?

Mix is not being dispensed from feeder tank

Where

Where did you see the problem? (Production Line, Machine and Location)

Line X feeder tank

Which

Which trend (or pattern) did you see? (Recurring or Sporadic)

Recurring (3rd time in 1 year)

When

When did the problem occur? (Changeover, normal operation, PM or start-up)

Normal operation

Who

Is the problem related to skill? (Either skill dependent or skill independent)

Skill independent

How

How is state changed from normal?

Paddle is not turning

Phenomenon Summary

Use all answers from 5W+1H to construct a description of the issue

(HOW+WHAT+WHERE+WHEN+WHICH+WHO)

The paddle isn’t turning and the mix is not being dispensed from the feeder in the Line X feeder tank in downfeed during normal operation, it’s recurring (it has happened 3 times in 1 year) and was skill independent.

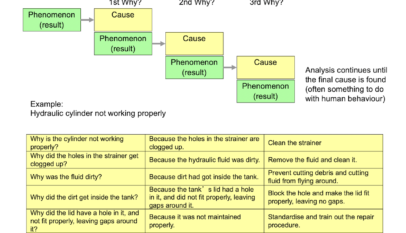

Step 2. Why-why analysis

Why

Answer

Why (The paddle isn’t turning and mix is not being dispensed from feeder in Line X feeder tank in downfeed during normal operation, it’s recurring (it has happened 3 times in 1 year) and was skill independent)

Gearbox was seized

Why (Gearbox was seized)?

Lubrication failure

Why (Lubrication failure)?

Mix had contaminated gearbox oil

Why (Mix had contaminated gearbox oil)?

Mix was spilling on top of the seal of gearbox

Why (Mix was spilling on top of the seal of gearbox)?

Mix feeder design allows mix to leak onto gearbox – design flaw

Step 3. Major code

Major Code

Description

Mech

Mechanical

Elec

Electrical

Oper

Operational

Compound

Compound, Mechanical, Electrical or other

Hydr

Hydraulic

Pneum

Pneumatic

Fasten

Fasteners

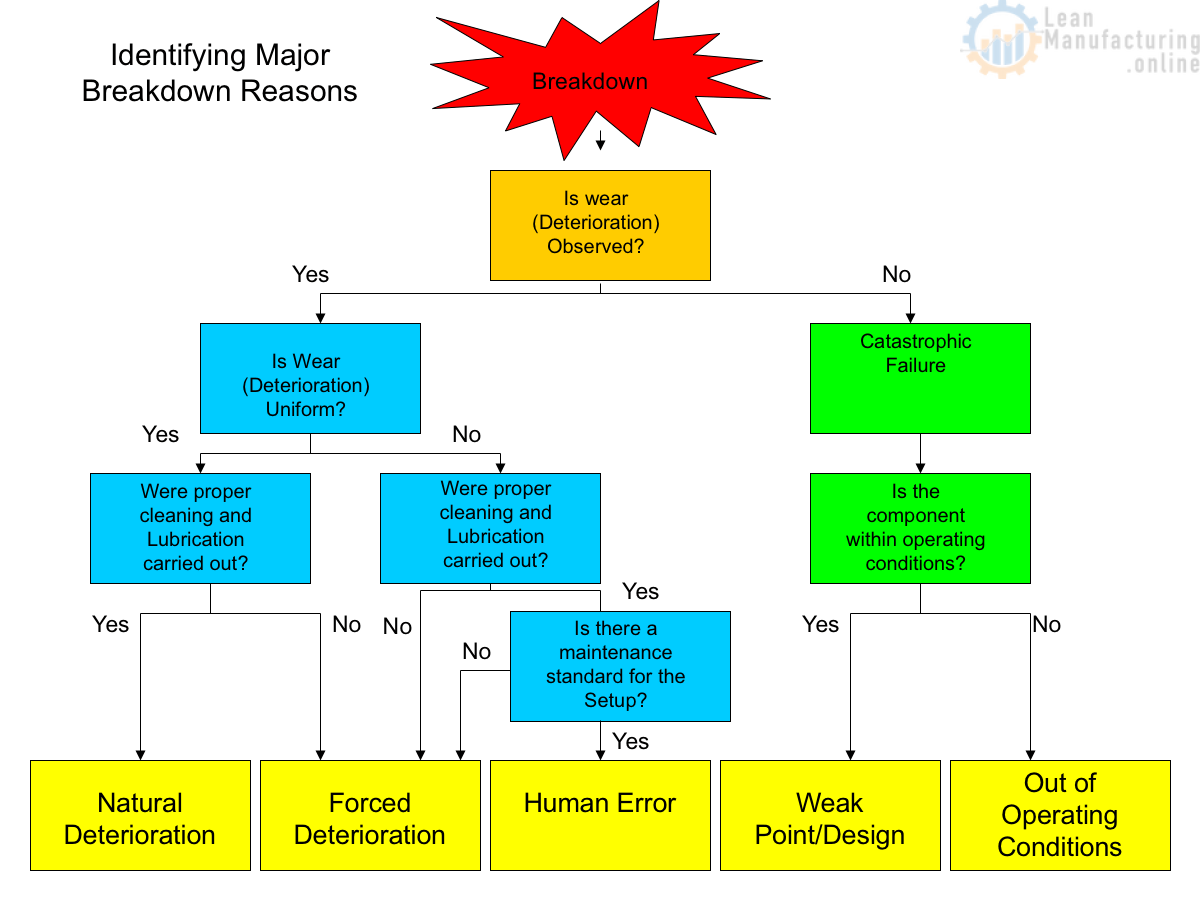

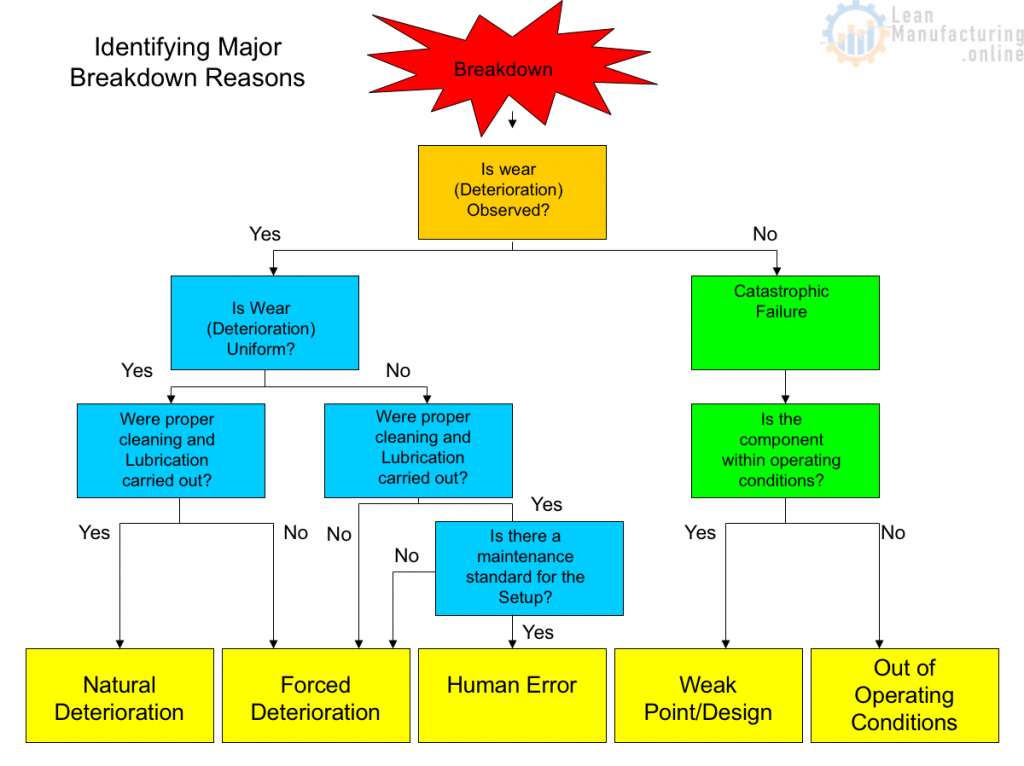

Step 4. Breakdown Reason

Breakdown Causes described here

Immediate Actions Taken

Description

Example

What did you do immediately to put it back to operating condition

Cleared mix spillage and replaced gearbox

Step 5. Countermeasures

Countermeasure

Description

Example

Immediate

What can you do right now to prevent recurrence of the breakdown

Replace with “sealed” gearbox to prevent future mix contamination

Intermediate

Is there a better solution to reduce loss?

Replace gearbox oil every 60 days

Long term

What is solution to eliminate future re-occurrences?

Design and install new seal in all tanks

Visual indicator

Can we use visual indicator to detect issue? Anything we can actively do to show the abnormality before it happens?

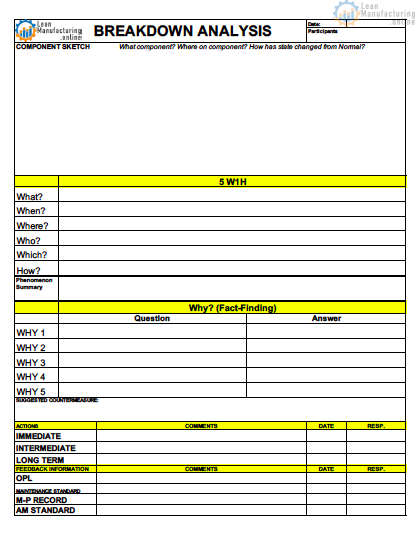

Breakdown Analysis Template

To download breakdown analysis template, follow this link