Planned Maintenance

Mastering Maintenance Planning: Steps to Boost Efficiency

Effective maintenance planning and scheduling are crucial for increasing productivity and ensuring smooth operations. This blog post delves into practical steps and best practices to optimize your maintenance processes, minimize downtime, and enhance overall efficiency.

Read More »Types of Maintenance Strategies for World-Class Operations

In the competitive landscape of today's manufacturing, strategic maintenance is more than just fixing what's broken. It's about aligning with World-Class Manufacturing principles to drive efficiency, reliability, and growth. From proactive measures like Preventive Maintenance to rapid actions in Emergency Maintenance, these strategies reflect a comprehensive understanding of both equipment…

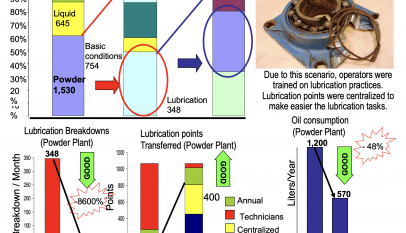

Read More »Planned Maintenance Case Study, Food Processing Plant

Discover how a food processing plant significantly improved its efficiency and reduced equipment breakdowns by implementing a planned maintenance approach. With a 40% reduction in breakdowns and a 20% increase in overall equipment effectiveness (OEE), this case study highlights the importance of a proactive and well-structured maintenance program for enhancing…

Read More »Preventive maintenance plan (PM program). Fundamental Phase Action Plan

There are seven very distinct elements or clusters to put in place in the Fundamental Phase. The elements are in a natural “make sense” order; some can be completed simultaneously with available resources. The last one, “Basic Maintenance Management,” can and should be inserted at the right time to aid…

Read More »