Planned Maintenance

Boost Your Preventive Maintenance Performance with a Targeted Gap Analysis

Unleash the full potential of your preventive maintenance program by conducting a targeted gap analysis. This powerful tool evaluates your current maintenance approach, identifies areas of inefficiency, and helps prioritize improvements for maximum effectiveness. Discover the key steps to implementing a successful gap analysis, from defining the scope to developing…

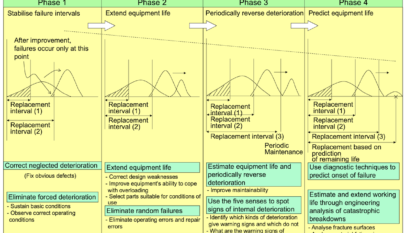

Read More »World-Class Maintenance. Switching from firefighting mode to planned system

World-class maintenance is a proactive approach to equipment maintenance that emphasizes prevention, planning, and continuous improvement. It requires a shift from a reactive, firefighting mode to a planned system that anticipates and addresses maintenance needs before they become critical. This shift in mindset and approach can help organizations reduce downtime…

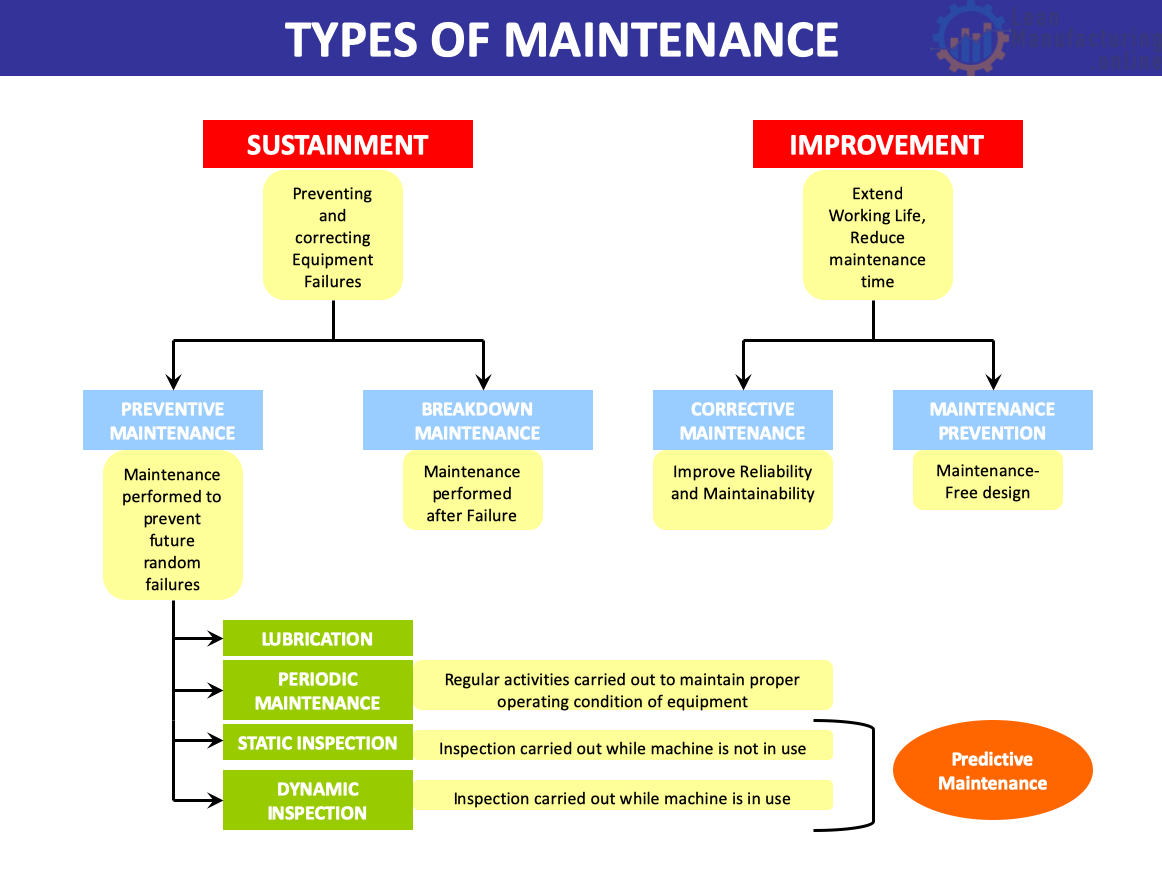

Read More »The Different Types of Maintenance

Manufacturing has four main types of maintenance: reactive, preventive, predictive, and corrective. Each has unique benefits and challenges.

Read More »TPM Pillar Self Assessment

5S Autonomous Maintenance Early Equipment Management Education and Training Focused Improvement Manufacturing Support Planned Maintenance Quality Safety, Health and Environment TPM World Class Manufacturing

The TPM Self Assessment’s purpose is to provide information to assist in running the factory. By showing the strengths and weaknesses of each TPM pillar using a structured approach.

Read More »