Planned Maintenance

Skills

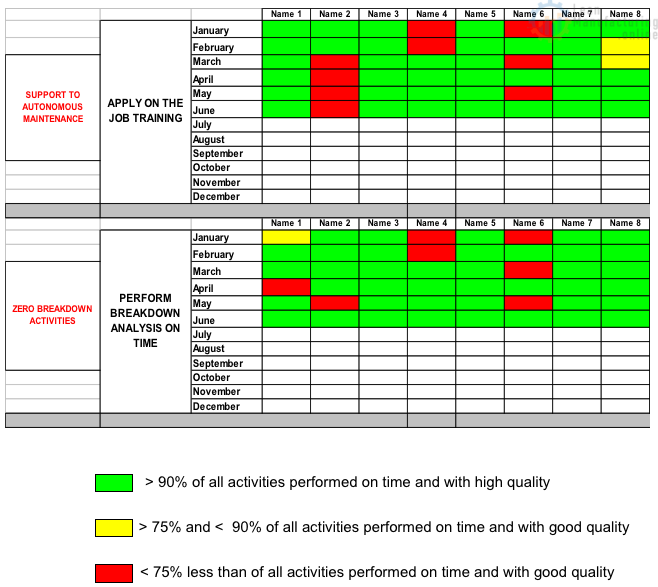

PM Element 8. Abilities Matrix During the progress of TPM, improving the tradesmen’s skills will be necessary. The first step is to identify which skills are required for the tradesmen. This information makes it possible to develop the abilities matrix and the training plan. Some questions about their skills to…

Read More »Spare Parts Administration

PM Element 7. Indicators The Importance of Spare Parts Administration Spare parts administration is crucial for organizations that rely on equipment to operate. If a breakdown or failure occurs, having spare parts on hand can reduce downtime, minimize production losses, and improve customer satisfaction. Additionally, a well-managed spare parts program can…

Read More »Reduce Maintenance Expenses

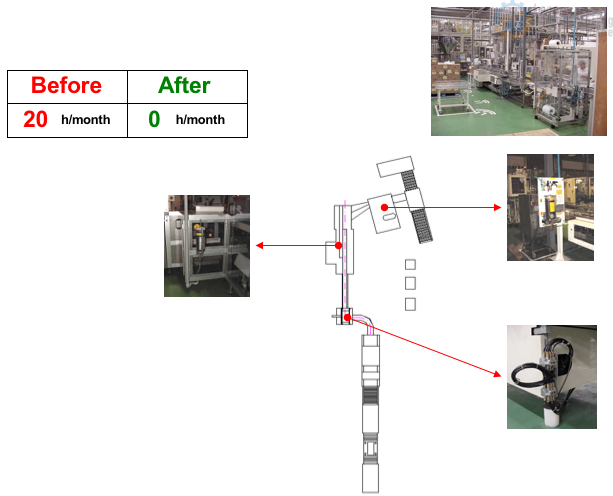

PM Element 6. Planned Activities The target is not to reduce the number of tradesmen in the factory. The main objective is to change from a reactive approach (firefighters) to a proactive approach (preventing breakdowns). The factory needs to develop a system of planned activities to use the maintenance resources…

Read More »Lubrication

PM Element 5. LUBRICATION PLAN Step 1 Identify the component that needs to be lubricated. Step 2 Determine the right type of lubricant. Step 3 Determine the right method and tools to perform lubrication. Step 4 Determine the right frequency. Daily, weekly, monthly, quarterly. Step 5 Identify if downtime is necessary…

Read More »