Approximately 40% of machine elements are subject to rubbing and friction of some kind, and correct application of the right lubricants to these parts serves, among other things, to:

- Reduce friction (and hence reduce loss of power)

- Ensure smooth sliding movement

- Prevent wear

- Prevent overheating and seizure

- Provide a cooling effect

- Remove dirt and debris from rubbing surfaces

- Prevent corrosion and erosion

- Prevent noise and vibration

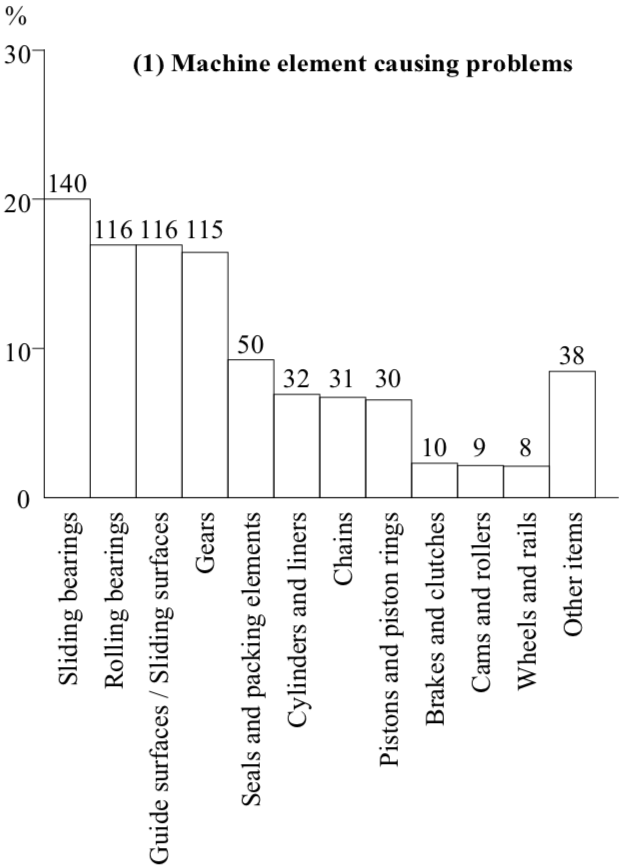

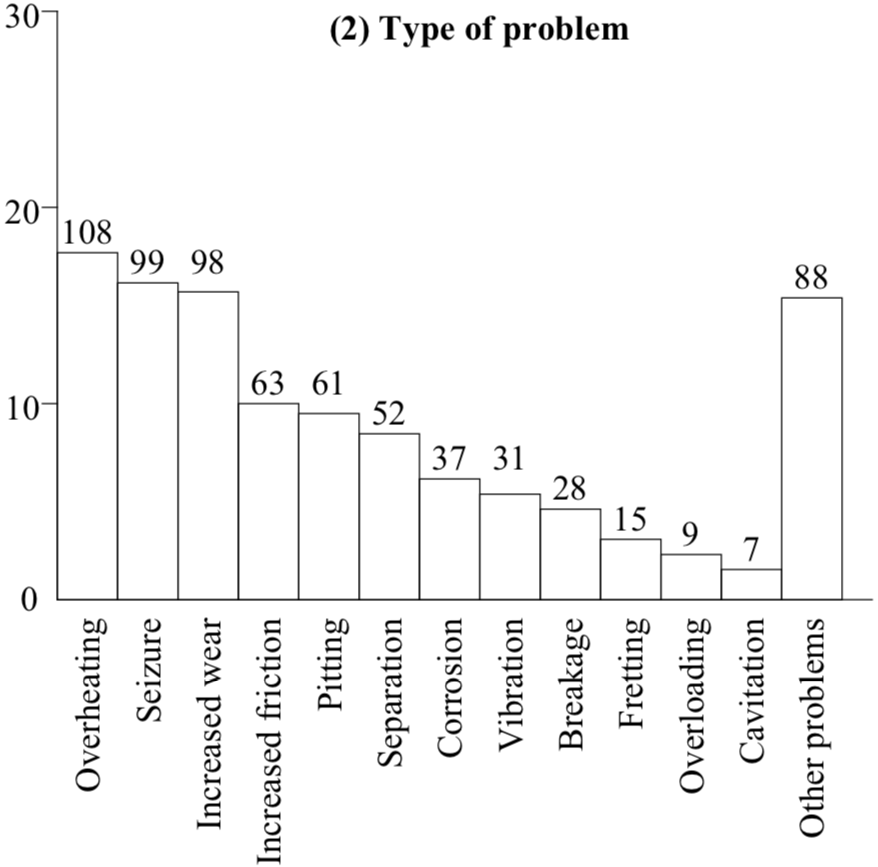

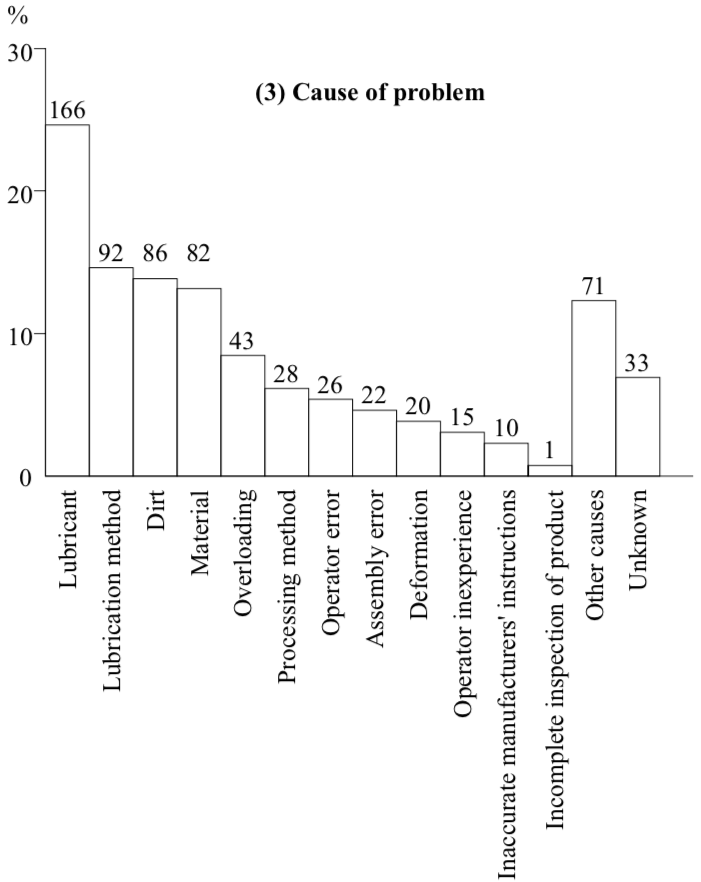

Proper lubrication can therefore help to prevent equipment underperformance or failure, as well as increase productivity and reduce operating and maintenance costs, thereby delivering tangible economic benefits. In practice, wear, deterioration, or failure of equipment can often be traced, directly or indirectly, to lubrication problems (see Figure “Equipment Failures (survey by Japan Society of Mechanical Engineers)”).

Managing lubrication means managing materials and technology. Lubrication materials management involves purchasing, receiving, and storing the required lubricants, paying for them, and disposing of them after use. Lubrication technology management, on the other hand, means observing the four basic rules of lubrication (using the correct lubricant, in the correct amount, by the correct method, and at the correct time) and is therefore applied on the shop floor. Some common problems relating to lubrication are discussed below, together with possible solutions.