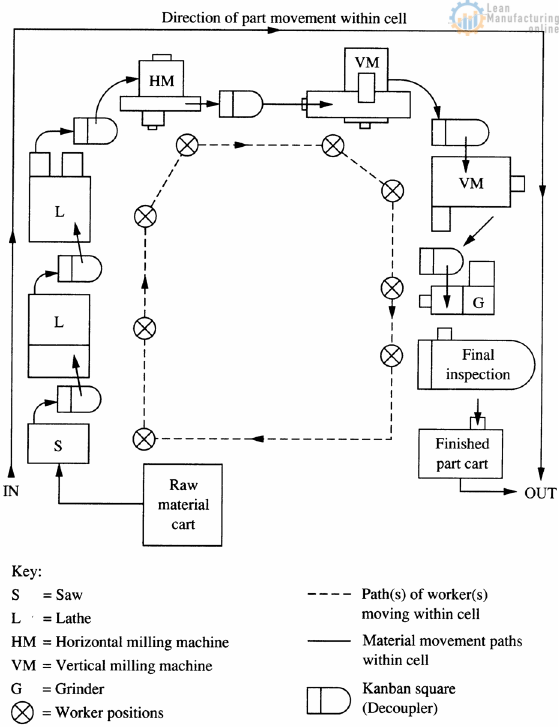

One-piece flow is a manufacturing process in which a single product or unit is produced simultaneously rather than multiple units in a batch. This approach, also known as single-piece flow or continuous flow, is a key principle of lean manufacturing, a methodology that seeks to minimize waste and optimize production efficiency.

One-piece flow allows for a more efficient and streamlined production process by eliminating the need for batching, which can lead to delays and inefficiencies due to the need to set up and changeover equipment for different batches. Instead, with one piece flow, each product moves through the production process at its own pace, allowing for a more flexible and responsive production process.

One-piece flow also allows for greater flexibility in the production process, allowing easy adaptation to changes in demand or product design. Additionally, it allows for greater quality control, as each product is produced and inspected individually rather than as part of a batch.

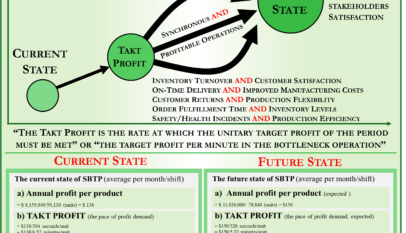

One-piece flow also reduces inventory and storage costs, as there is no need to keep large amounts of inventory on hand to account for batch production and delays. This, in turn, helps to reduce overall costs and improve profitability.

Implementing a one-piece flow can be challenging, as it requires a significant change in how production processes are designed and managed. It requires a shift in mindset and culture, focusing on continuous improvement and flexibility.

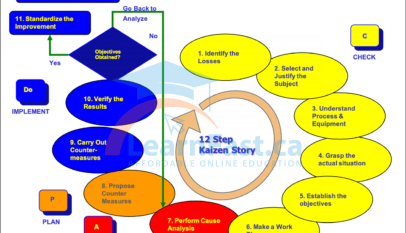

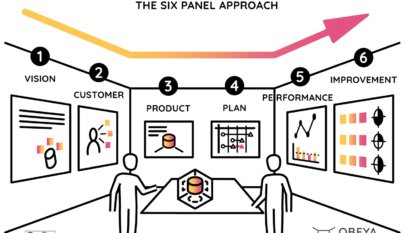

To implement one piece flow, companies must first identify bottlenecks and areas of inefficiency in their production process. They must then work to eliminate these bottlenecks and optimize their production process to allow for a smooth flow of products. This may involve redesigning production lines, implementing new technology, or training employees on new skills.

Overall, one-piece flow is a powerful manufacturing process that can significantly improve efficiency, flexibility, and profitability. While it can be challenging to implement, companies that can successfully adopt a one-piece flow can reap significant benefits in the long run.