Background

It’s no exaggeration to say that an organization’s strength hinges on the caliber of its human resources. Enhancing the competencies of our team through various initiatives elevates the entire organization.

However, despite efforts to develop our talent, continuous improvement isn’t always reflected at the financial level. If people-centric management and its expertise aren’t integrated into the organization’s management system, generational transitions can lead to the loss of both key talent and critical know-how. As W. Edwards Deming famously said, “Management is responsible for 94% of organizational problems.”

The processes and expertise we rely on today are the result of past improvements and lessons learned. These must be continuously refined to adapt to changing business environments. However, the drive for improvement must come from individual managers’ full engagement. Forced improvement activities often lead to resistance and superficial compliance. Addressing this challenge is crucial for all managers, especially top leadership. This need inspired the development of Strategic KAIZEN methodologies, aiming for synchronized and profitable operations (the ideal state of operations).

In today’s business landscape, numerous management methods and techniques are available. Yet, even the most sophisticated tools won’t yield desired results unless the foundational elements are properly established.

Moment of Decision

”We feel we’ve reached maximum possible cost improvement and it’s still not enough”. Many leaders admit this privately. For example, a European manufacturer of auto components – we’ll call it Vaspare Corp.– began to lose its way regarding target profit. Years ago, Vaspare had launched an ambitious program to become a Lean enterprise hoping to achieve better quality, lower costs and on-time deliveries. After the first six months, senior executives noted that sales fell by 10.2% and operating profit margin decreased to 7.1% compared to a 10% target. Through their Kaizen activities, only 3.7% of the 5% cost saving target was achieved. In the next six months, the Vice President of Operations had quite good operational results but the operating profit margin fell again.

Vaspare’s challenge is common, with sometimes abrupt decisions: some corporations have experienced sharp drops of 24% in operating profits amid market pressure to cut prices (Tesla) and others have resorted to massive layoffs to contain costs (Ford). Like Vaspare, Tesla and Ford, the focus on maximizing flow and satisfying customer needs often leads to forgetting real purpose – to make profit for stakeholders. When the financial results show that they are not so profitable, it is already too late and they are forced to make painful decisions. They never examine how to modify or change their cost improvement system. External investors and board members start to question the skill and commitment of senior executives.

In our experience, the root cause of underperformance lies in the strategic productivity improvement approach, not in the managers’ skills or efforts. Vaspare Corp. embraced Strategic KAIZEN thinking and methodology to achieve both annual and long-term profitability goals through continuous strategic enhancement of all productivity factors.

10 Tormenting Questions: The Voice of Senior Managers at Vaspare

Despite their hard work to enhance production processes, there was often a gap between managerial vision and on-the-ground execution. This misalignment frequently led to improvements that didn’t meet business expectations. Even after years of departmental KAIZEN initiatives, profits were below target, and traditional KAIZEN activities had lost direction, failing to address the company’s real needs. There was an urgent need for systematic improvements in productivity, quality, and cost efficiency, but the current system wasn’t delivering the required profitability.

Several factors contributed to this issue: overall improvement goals were not well-aligned with those of field leaders, and improvement activities were often left to them without adequate support when needed. Additionally, middle managers struggled to leverage the successful experiences of field leaders. Senior managers recognized the need to reform middle management to develop human resources for systematic production improvement, but they were less aware that they, too, needed to reform their approach to continuous improvement and strategy formulation.

In Strategic KAIZEN thinking, continuous management reform is an organizational asset. The ability to implement management reforms – responding to changes in the business environment by collaborating between management and the front line, and formulating and executing strategies aimed at growth, development, and profit improvement by strategically increasing productivity or continuously reducing non-productive costs – is not something that can be acquired overnight. It is considered an organizational asset that takes time to develop.

The key to manufacturing reform lies in establishing a management system that embodies the vision of top management, enhances the strategic and systematic improvement capabilities of middle managers and leaders, and consistently delivers business results. This is what the Strategic KAIZEN methodology offers.

But let’s revisit the 10 pressing questions from senior management at Vaspare, often heard in meetings, hallways, and sometimes in the production departments. They went something like this:

- How can we ensure our policies and ideas are fully understood and implemented by all employees?

- Are we truly at the peak of our improvement capabilities, or is there untapped potential in our current productivity?

- What steps can we take to break down silos and achieve holistic optimization of our operations?

- Why aren’t the significant cost reductions from operational improvements reflected in our financial statements?

- How can we enhance the accuracy and reliability of our cost calculations by including non-productivity costs?

- What new methods can we employ to link continuous improvement results to overall business performance?

- How can we better plan, allocate, and especially reduce indirect costs to boost efficiency?

- What specific behaviors do we need to adopt as managers and employees to achieve our business goals through strategic and daily improvements?

- How can we ensure that our improvement activities consistently lead to tangible gains in expected business performance?

- Is our Just-In-Time (JIT) production truly effective?

These questions highlight the ongoing need for strategic and systematic improvements to meet business goals. Let’s drive our future success by turning these questions into actionable strategies with the Strategic KAIZEN methodology!

10 Key Challenges: From Senior Manager Insights to Strategic KAIZEN Expertise

Over time, senior managers’ questions evolved into 10 Critical Issues identified by Strategic KAIZEN consultants as pivotal for adopting the Strategic KAIZEN methodology:

1) Inconsistent Targets and Activities: While senior management’s objectives were broken down for each division, individual activity goals lacked coherence and alignment with the expected financial outcomes.

2) Limited Optimization: Divisions address improvement topics in isolation, failing to achieve holistic optimization and not breaking down inter-divisional barriers.

3) Uncertainty About Improvement Potential: Despite assertions that no further improvements were possible, there was no evidence to support these claims.

4) Disconnect Between Improvements and Results: There is a gap between the calculated outcomes of improvement activities and the actual business results, leading to mistrust in the improvement metrics.

5) Traditional Cost Calculations: The total non-productivity costs were not calculated, leading to inappropriate prioritization of improvements, poor profit calculations, and incorrect pricing.

6) Lack of Communication: Top management’s directions, goals, and strategies were not fully understood at the operational level.

7) Unclear Employee Behavior: The plan for achieving business goals was unclear, and the required employee behaviors for improvements were not specified.

8) Ineffective Improvement Activities: Despite promoting various improvement activities, they did not enhance business performance, either operationally or financially.

9) Increasing Managers’ Motivation for Strategic Improvements: Top management’s involvement in improvements was low. To meet competition and enhance performance, it is crucial to activate motivation at all levels of Vaspare.

10) Continuous Overcoming of Constraints: There is a need for continuous identification and overcoming of constraints for further reforms without additional investment.

Senior managers at Vaspare recognized that Strategic KAIZEN fosters an organizational force, guiding both short-term and long-term improvements with a self-sustaining mechanism for enhancing productivity. Let’s break down barriers, align our goals, and drive our business to new heights with Strategic KAIZEN.

The Strategic KAIZEN Concept

The Just-In-Time (JIT) or “synchronization” concept is crucial, but achieving full and profitable synchronization is challenging for many manufacturing companies. For end manufacturers, like automobile companies that assemble and deliver finished products, JIT is efficient and often profitable enough. For suppliers providing parts and materials, JIT can be inadequate and profitability remains a significant challenge.

Both assembly companies and suppliers need a systematic, strategic productivity improvement system that integrates “synchronization” and “profitability.” Strategic KAIZEN is an ideal production management system for both, aiming to achieve synchronous and profitable operations through systematic strategic improvement of all productivity factors.

To successfully execute Strategic Productivity Improvements, follow these two basic rules: (1) adhere to the Strategic KAIZEN methodology, linking the company’s strategy for reducing non-productive costs to operations, and (2) apply Strategic KAIZEN concepts in each of the three phases of the methodology.

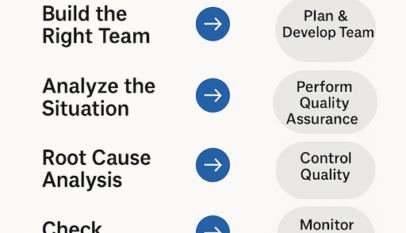

The Strategic KAIZEN Methodology: 3 Stages and 7 Steps

Stage 1 – Continuous Measurement and Interpretation:

Process 1: Studying the Potential for Strategic Systematic Improvement Points

Process 2: Calculating Ideal Takt Profit & Setting Stratified KAIZENshiro

Stage 2: Annual Development:

Process 3: Annual Financial Reconciliation (financial catchball)

Process 4: Annual Operational Reconciliation (operational catchball)

Process 5: Organizing, Planning and Learning for Strategic Kaizen

Stage 3 – Implementation and Management:

Process 6: Implementing Annual Feasible Strategic Kaizen Projects

Process 7: Results, Standardization, Horizontal Extensions and Future Plans

The 7 Strategic KAIZEN Principles

What makes Strategic KAIZEN different! The thinking and action processes of Strategic Kaizen for guiding strategic systematic improvement implementations can be summarized as: (1) flow, ( 2) pull, and (3) synchronization at Takt Profit (and implicitly at takt time to achieve the ideal flow state namely Synchronous Profitable Operations).

For the continuous and consistent direction of the flow towards the state of Synchronous Profitable Operations, the implementation of the Strategic Kaizen methodology considers the following seven basic principles:

Drive Synchronization and Profitability with Strategic KAIZEN!

Thank you for dedicating your valuable time and attention.

Lead the way to a brighter future! Alin Posteucă