Safety

Understanding Unsafe Acts: Definitions, Dangers, and Prevention Measures

In this blog post, we will cover the fundamental aspects of safety, which include identifying unsafe conditions, unsafe actions, near misses, and accidents. It emphasizes the significance of acknowledging and managing potential hazards while emphasizing the importance of following safety protocols, using personal protective equipment, and adopting a safety-conscious culture.…

Read More »Safety, Health and Environment Investigation Report and Analysis

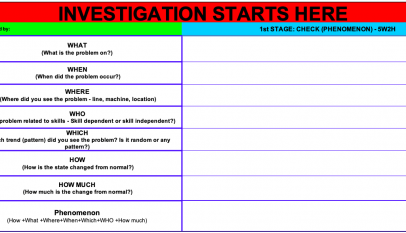

5 Why Analysis Blog Cap-Do Lean Six Sigma PM-analysis Root Cause Analysis Safety Safety, Health and Environment TPM

All modern manufacturing facilities use principles that “all accidents are preventable,” but sometimes incidents or accidents can still happen. Gathering as much data as possible and analyzing it to prevent a recurrence is essential. Investigation Report Let’s review the first part – [ Incident Reporting ] A. To be completed…

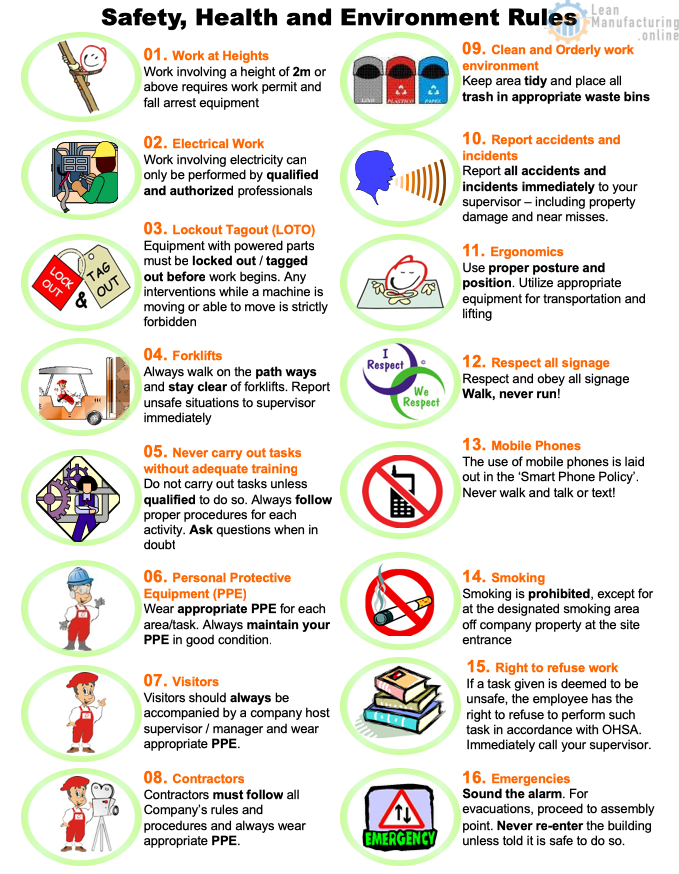

Read More »Safety, Health and Environment Rules – SHE Pillar

Every manufacturing facility should have a set of SHE rules for workers and visitors/contractors. Rules must be designed per company policies as well as local legislation. Please see below examples of Safety, Health, and Environment Rules: Work at Heights Work involving a height of 2m or above requires a work…

Read More »Safety, Health, and Environment TPM pillar

SHE pillar vision is to cultivate a Continuous Improvement culture that achieves a sustained record of Safety, Health, & Environmental excellence & realizes our vision: ZERO accidents, ZERO incidents, ZERO losses. The SHE Pillar is the cornerstone TPM Pillar that supports and lends stability to the overall continuous improvement process…

Read More »