The Strategic Importance of Maintenance in Modern Manufacturing

In today’s competitive manufacturing landscape, maintenance strategies play a pivotal role in ensuring operational efficiency, reliability, and sustainability. Aligning with the principles of World-Class Manufacturing (WCM), these strategies are not merely about fixing what’s broken but are integral to an organization’s overall performance and growth. They are tailored to a system’s specific needs, risks, and objectives, reflecting a deep understanding of both the equipment and the broader organizational goals. From predicting failures before they occur to responding to emergency breakdowns, these strategies encompass a holistic approach to maintenance grounded in both technology and organizational insight.

Comprehensive Maintenance Strategies for Operational Excellence

- Preventive Maintenance (PM): Through scheduled checks and servicing, this method avoids unexpected breakdowns and ensures reliability. It embodies the principle of foreseeing and preventing problems before they occur, enhancing overall productivity.

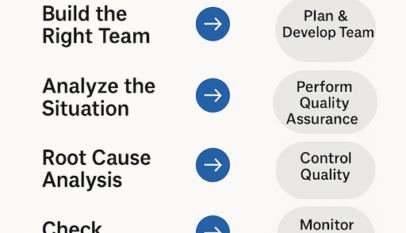

- Corrective Maintenance (CM): After a failure, this approach identifies root causes and implements corrective actions. It encourages learning from mistakes and refining processes, fostering a culture that consistently strives for betterment.

- Time-based Maintenance (TBM): With its focus on timely and regular interventions, TBM ensures that machinery functions at optimal levels. This systematic method mirrors the precision and coordination found in top-tier manufacturing systems.

- Failure Finding Maintenance (FFM): Targeting detection and foresight, FFM uncovers hidden failures before they lead to functional failure. It aligns with the pursuit of operational excellence, seeking to discover and rectify inefficiencies.

- Risk-based Maintenance (RBM): This strategy prioritizes activities based on potential risks, reflecting strategic resource allocation. Efforts are focused where they can have the greatest impact, mirroring the practices of the best in the industry.

- Condition-based Maintenance (CBM): Focusing on real-time monitoring and responsiveness, CBM maintains machinery based on its current condition. It exhibits the principle of flexibility, adapting to changes to maintain peak performance.

- Predictive Maintenance (PDM): Utilizing advanced technology to anticipate failures, this forward-thinking approach minimizes downtime. It embodies the philosophy of preparing for challenges in advance and crafting precise solutions.

- Deferred Corrective Maintenance: By strategically delaying corrective actions for non-critical issues, this approach balances immediate needs with long-term goals. It exemplifies wisdom in prioritizing actions and maintaining equilibrium in operations.

- Emergency Maintenance (EM): This approach requires quick response and agility to deal with unexpected failures. Reflecting practices that emphasize rapid decision-making and execution, it ensures resilience when facing unforeseen challenges.

Towards a Lean, Agile, and Competitive Manufacturing Environment

The spectrum of maintenance strategies described above transcends the traditional view of repair and upkeep, reflecting a sophisticated understanding of manufacturing processes and organizational needs. Whether it’s the preemptive intelligence of Preventive Maintenance, the adaptability of Condition-based Maintenance, or the rapid responsiveness of Emergency Maintenance, each approach serves a unique purpose in the manufacturing ecosystem. By adopting and integrating these strategies, organizations can foster a culture of continuous improvement, maximize the life cycle of their assets, reduce downtime, and drive toward operational excellence. These practices, rooted in the principles of World-Class Manufacturing, contribute to a lean, agile, and competitive manufacturing environment that meets the demands of the modern global economy.