In today’s challenging economic climate, cutting maintenance costs has become imperative for many asset-intensive industries. Maintenance budgets often account for 20% to 40% of the total annual budget, making them prime targets for cost reduction. Here’s how you can strategically reduce maintenance costs without compromising on quality and efficiency.

Understanding Maintenance Costs

Maintenance costs are a consequence of various factors:

- The amount of preventive maintenance performed

- The frequency of equipment failures

- The workforce size, including employees and contractors

To effectively lower these costs, focus on increasing productivity, using fewer materials, and reducing the services purchased.

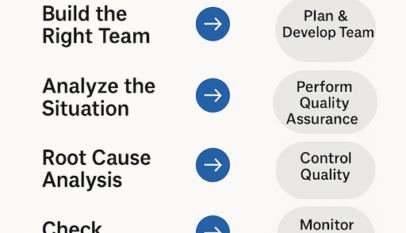

Step 1: Tackle Low Maintenance Productivity

A typical maintenance day is filled with inefficiencies, such as waiting for tools, permits, and instructions. To improve productivity:

- Implement a structured planning and scheduling process

- Increase wrench time from 30% to 45%

- Aim for a 35% increase in workforce productivity without additional hiring

Step 2: Improve Your Preventive Maintenance (PM) Program

A significant portion of PM tasks may be ineffective. To enhance your PM program:

- Analyze your current PM tasks to identify high-labor and high-cost areas

- Use the Pareto principle to prioritize failure modes

- Ensure that revised PM tasks align with fundamental maintenance principles

Step 3: Eliminate Repeat Equipment Failures

Recurring equipment failures can drain resources and increase costs. To address this:

- Analyze corrective maintenance history

- Create Pareto charts for high-cost and frequent failures

- Conduct root-cause analyses to identify and eliminate the causes of these failures

Step 4: Improve Contracts and Rates

High-cost structures often result from poorly negotiated contracts. To optimize your contracts:

- Focus on essential requirements to avoid unnecessary costs

- Incentivize contracts to promote ownership and eliminate waste

- Engage your procurement team to negotiate better rates

A well-optimized preventive maintenance (PM) program is crucial to this process. By thoroughly analyzing your PM tasks, you can eliminate those that are ineffective, duplicative, or overly frequent, thus ensuring that your maintenance efforts are focused on preventing the most critical failures. This targeted approach reduces unnecessary labour and material costs and improves overall equipment reliability. Integrating this improved PM program with enhanced productivity measures, addressing root causes of repeat failures, and negotiating better contracts will create a comprehensive strategy for lowering maintenance expenses while maintaining high standards of reliability and performance.