Blog

Unleash SAP: A Guide for Asset Management

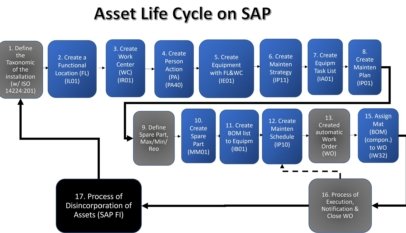

Get to grips with asset management using SAP, an essential tool for maintenance departments. This guide offers a step-by-step approach to streamline your asset lifecycle, from creating a functional location to decommissioning assets. Learn how to effectively coordinate maintenance plans, manage spare parts, and more, leveraging SAP's capabilities to optimize…

Read More »Nine blind spots project managers should avoid

Navigating the complexities of project management successfully often involves avoiding common "blind spots". These can range from ignoring stakeholder input to mismanaging project scope. This article shines a light on nine such blind spots, providing valuable insights into how project managers can recognize and proactively address these pitfalls to ensure…

Read More »Empowering Management with Training Within Industry: A Deep Dive into Second-Line Supervisor Job Instructions

The guide outlines four key steps for initiating this process: creating a timetable for training needs, developing job breakdowns, encouraging a clean and well-arranged workplace, and following the four steps of the original job instruction card for supervisors. To maintain the use of job instructions, managers should regularly review time…

Read More »Crafting a professional email

Discover the art of professional emailing with our comprehensive guide. From crafting compelling subject lines to choosing the right greetings and closures, we delve into every aspect that contributes to a successful professional email. Learn how to articulate your thoughts clearly, attach files effectively, and use the CC and BCC…

Read More »