Blog

Mastering Problem-Solving and Decision-Making Skills with Toyota Kata

Toyota Kata is a powerful tool for any organization seeking continuous improvement. By following the four-step process of understanding the direction, grasping the current condition, establishing the target condition, and conducting experiments, individuals and teams can develop the problem-solving and decision-making skills they need to succeed.

Read More »Seven Ways to Create a Continuous Improvement Culture

Creating a continuous improvement culture is crucial to any organization's success. In this article, we explore seven ways to build a continuous improvement culture in your workplace, including developing a shared vision, empowering employees, fostering collaboration, providing training and coaching, recognizing and rewarding improvement efforts, using data and metrics to…

Read More »Continuous Improvement

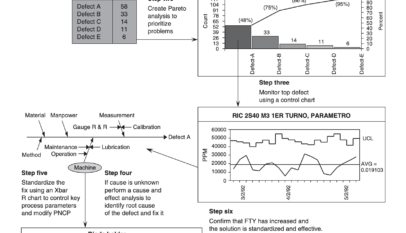

Continuous improvement is critical in manufacturing to maintain quality, increase productivity, and reduce costs. We will focus on collecting data for the process, prioritizing problems, monitoring defects, identifying the root cause of defects, standardizing the fix, and confirming the solution's effectiveness. By following these steps, companies can continuously improve their…

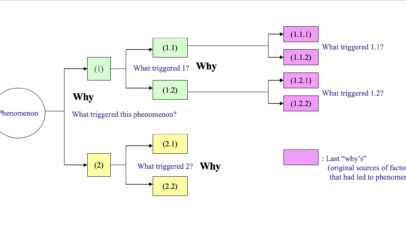

Read More »Quality Improvement. Root Cause Analysis

Root cause analysis (RCA) is a technique that is used to identify the reason for the underlying issues. Instead of only addressing the symptoms of a problem, it is a systematic procedure for locating and addressing its underlying causes. By addressing the core causes of the issue, RCA seeks to…

Read More »