Blog

How Real-Time Condition Monitoring Can Predict and Prevent Equipment Failures

Real-time condition monitoring is a powerful tool that can help maintenance and reliability professionals predict failures and mitigate production downtime seamlessly. By identifying critical equipment, defining key performance indicators (KPIs), installing sensors, using predictive analytics, implementing automated alerts, and taking corrective action when necessary, professionals can reduce downtime, increase productivity,…

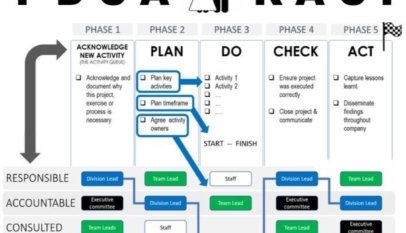

Read More »Streamlining Problem-Solving with the PDCA-RACI Framework

Combining the PDCA and RACI methodologies can create a symbiotic problem-solving methodology that emphasizes clear communication, defined roles and responsibilities, and continuous improvement. In the planning stage, the RACI framework is used to define the roles and responsibilities of team members involved in the problem-solving process. In the doing stage,…

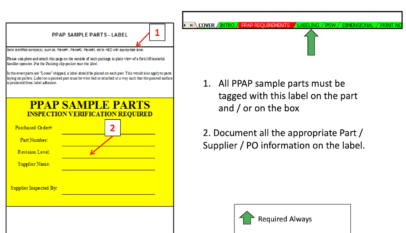

Read More »Ensuring Quality in the Automotive Industry with PPAP

The Production Part Approval Process (PPAP) is a critical tool used in the automotive industry to ensure that parts and components used in vehicles meet the highest quality standards. Developed by the Automotive Industry Action Group (AIAG), the PPAP process has become the de facto standard for automotive suppliers. However,…

Read More »Capital Expenditure (CapEx) vs. Operational Expenditure (OpEx)

CapEx and OpEx are both essential for running a business, but they have different impacts on a company's financial position.

Read More »