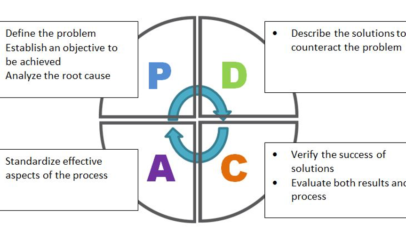

PDCA

Harnessing Business Excellence in Manufacturing Through the PDCA Approach

Explore the transformative power of the PDCA approach in driving business excellence within the manufacturing sector. Discover key performance indicators and strategies that promote a robust company culture, enhancing employee satisfaction and competitive advantage.

Read More »Top 100 Reasons for Failure

When things go awry, it's tempting to chalk it up to 'human error,' but that's rarely the whole story. In a complex world where outcomes are influenced by a multitude of factors, understanding the real reasons behind failures can be enlightening and transformative. From the missteps in methods to material…

Read More »How to use PDCA to improve your Production Efficiency

The improvement cycle is a continuous process of identifying problems or opportunities, developing a plan to address them, implementing the plan, and evaluating the results. It involves repeating this process to make ongoing improvements.

Read More »Embracing Kaizen: The Path to Continuous Improvement and Organizational Success

Discover the power of Kaizen, a Japanese philosophy of continuous improvement, in fostering organizational success. Learn about its origins, historical context, and the crucial roles of the Standardize-Do-Check-Act (SDCA) and Plan-Do-Check-Act (PDCA) cycles in driving process improvement and innovation. Embrace Kaizen to create a culture of adaptability and excellence in…

Read More »