Blog

The 1-10-100 Rule

The 1:10:100 rule is a principle that suggests it is more cost-effective to invest in preventative measures to avoid problems rather than waiting until problems occur and trying to fix them later. The rule states that for every $1 spent on prevention, $10 can be saved on corrective measures, and…

Read More »How can Shadow boards improve the efficiency of your process?

Shadow boards are tools which help organize workstations, setup carts, tool cribs and practically anything that needs organizing! Let me take you through an example of how a company increased their productivity by 35% just by installing a simple shadow board. Shadow boards help find a home for every object;…

Read More »Create, issue and implement maintenance work order

To create and issue a maintenance work order, follow these steps: Identify the problem or issue that needs to be addressed. This could be something that a building tenant has reported or something that you have noticed during a routine inspection. Determine the scope of the work that needs to…

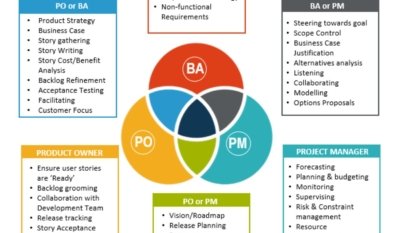

Read More »Project Manager vs. Business Analyst vs. Product Owner

A project manager is responsible for the overall planning, execution, and delivery of a project. They work with a team of people to ensure that the project is completed on time, within budget, and to the required quality standards. Some specific duties of a project manager might include the following:…

Read More »