Blog

One-piece flow

One-piece flow, Lean manufacturing, Just-in-time, JIT, production, manufacturing, process flow, process improvement, work cell, value stream, pull system, continuous flow, bottlenecks, efficiency, productivity, work balance, work measurement, Kanban, standard work, flow manufacturing, flow production, takt time, cycle time, work sequencing, work simplification, work standardization, work design

Read More »Pneumatic Cylinder Principles of Operation

Pneumatic cylinders are the unsung heroes in industrial automation, seamlessly converting compressed air into kinetic energy to drive operations. Dive deep into their principles of operation, from the basic piston movement to their various types and advantages, as we explore the mechanics behind these powerhouses of automation.

Read More »What is Systematic Maintenance?

Definition: Preventive maintenance is carried out according to a schedule and established according to the time or the number of units of use (produced). Even if time is the most common unit, other units can be used, such as the number of products manufactured, the length of products manufactured, the distance…

Read More »Kanban: Introduction

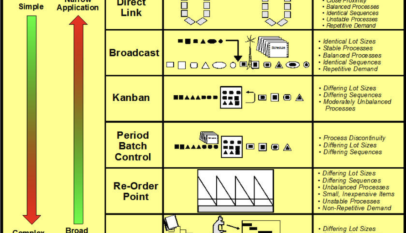

Kanban aims to minimize WIP (Work-In-Process), or inventory, between processes by ensuring that the upstream process produces parts only if its downstream process needs them. “Pull” means that the downstream workers withdraw or “pull” the parts they need from their upstream processes. What is it: Kanban is a Japanese term…

Read More »