Just in Time

Embracing The Toyota Way: A Practical Problem-Solving Framework for Improved Efficiency

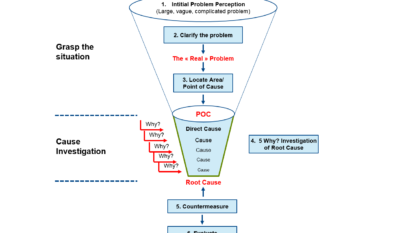

This framework was inspired by The Toyota Way, a management philosophy emphasizing continuous improvement and respect for people. The framework consists of five distinct stages: defining the problem, breaking down the problem, setting targets, analyzing root causes, and implementing countermeasures. By following this systematic approach, organizations can effectively address challenges,…

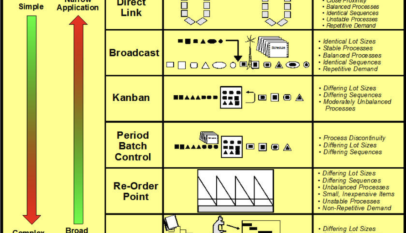

Read More »Types of material replenishment systems

Material replenishment is a critical component of effective supply chain management. There are several types of material replenishment systems available, each with its own strengths and weaknesses. In this post, we will explore the different types of material replenishment systems including the Kanban System, Just-In-Time (JIT) System, Material Requirements Planning…

Read More »Kanban: Introduction

Kanban aims to minimize WIP (Work-In-Process), or inventory, between processes by ensuring that the upstream process produces parts only if its downstream process needs them. “Pull” means that the downstream workers withdraw or “pull” the parts they need from their upstream processes. What is it: Kanban is a Japanese term…

Read More »Steps to create Value Stream Mapping

A Value Stream Map is… A tool that helps visualize and understand the flow of material and information as a product or service makes its way through the value stream: A high-level map that visually presents the flow of a product or service from supplier to customer can be used…

Read More »