Lean Six Sigma

Lean Six Sigma Black Belt Project

Discover how our comprehensive Lean Six Sigma project led to significant improvements in efficiency, quality, and business performance by leveraging the DMAIC approach and a suite of innovative tools. Learn how our expertise and proven methodologies can drive sustainable results and operational excellence in your organization.

Read More »A Comparative Analysis of Popular Continuous Improvement Methodologies: PDCA, DMAIC, A3, QRQC and 8D

Explore the differences between four popular continuous improvement methodologies - PDCA, DMAIC, A3, and 8D. This blog post offers a comprehensive comparison, examining their unique steps and applications, to help you choose the most suitable approach for your organization's improvement journey.

Read More »A Comprehensive Study of A3 DMAIC: Integrating Lean and Six Sigma for Continuous Improvement

We present a comprehensive study of A3 DMAIC, an integrated approach combining Lean and Six Sigma methodologies for continuous improvement. The post delves into the framework's five key phases: Define, Measure, Analyze, Improve, and Control. It also highlights the benefits of A3 DMAIC, including enhanced problem-solving, improved communication and collaboration,…

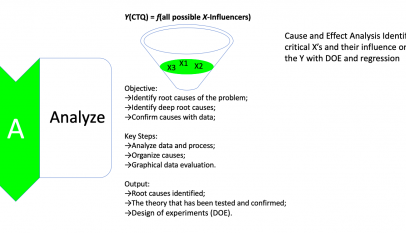

Read More »Analyze Phase of DMAIC in Lean Six Sigma

Dive into the Analyze phase of the DMAIC process in Lean Six Sigma, where teams identify the root causes of problems and develop a deeper understanding of the issues at hand. Discover the objectives, tools, and techniques used in this critical phase, such as Fishbone Diagrams, Five Whys, and Pareto…

Read More »