Lean

The 16 Big Losses and Related Costs

How does working patiently and persistently to eliminate the 16 Big Losses not only have the benefit of driving up OEEs, but also help greatly to drive down costs? If a plant has been working flat-out to meet demand, for example, with its operators doing overtime and holiday work, increasing…

Read More »How many wastes are in Lean?

The lean methodology defines 8 forms of waste: Transportation Inventory Over-processing Overproduction Waiting Motion Defects Underutilized skills Transportation waste Movement of material, paper, etc. that adds unnecessary time to the flow, increasing the risk of being lost, placed in the wrong location during transportation. Inventory waste Packaging or finished goods…

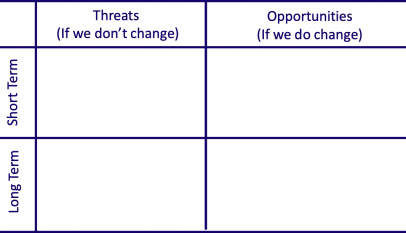

Read More »Threats and Opportunities Matrix

A tool to help understand the set of reasons why a project is necessary. List of “consequences if the problem is not fixed” and ‘benefits of making the change”. People are motivated by threats and opportunities; Identify the stakeholder group who needs to understand why the project is needed; Brainstorm…

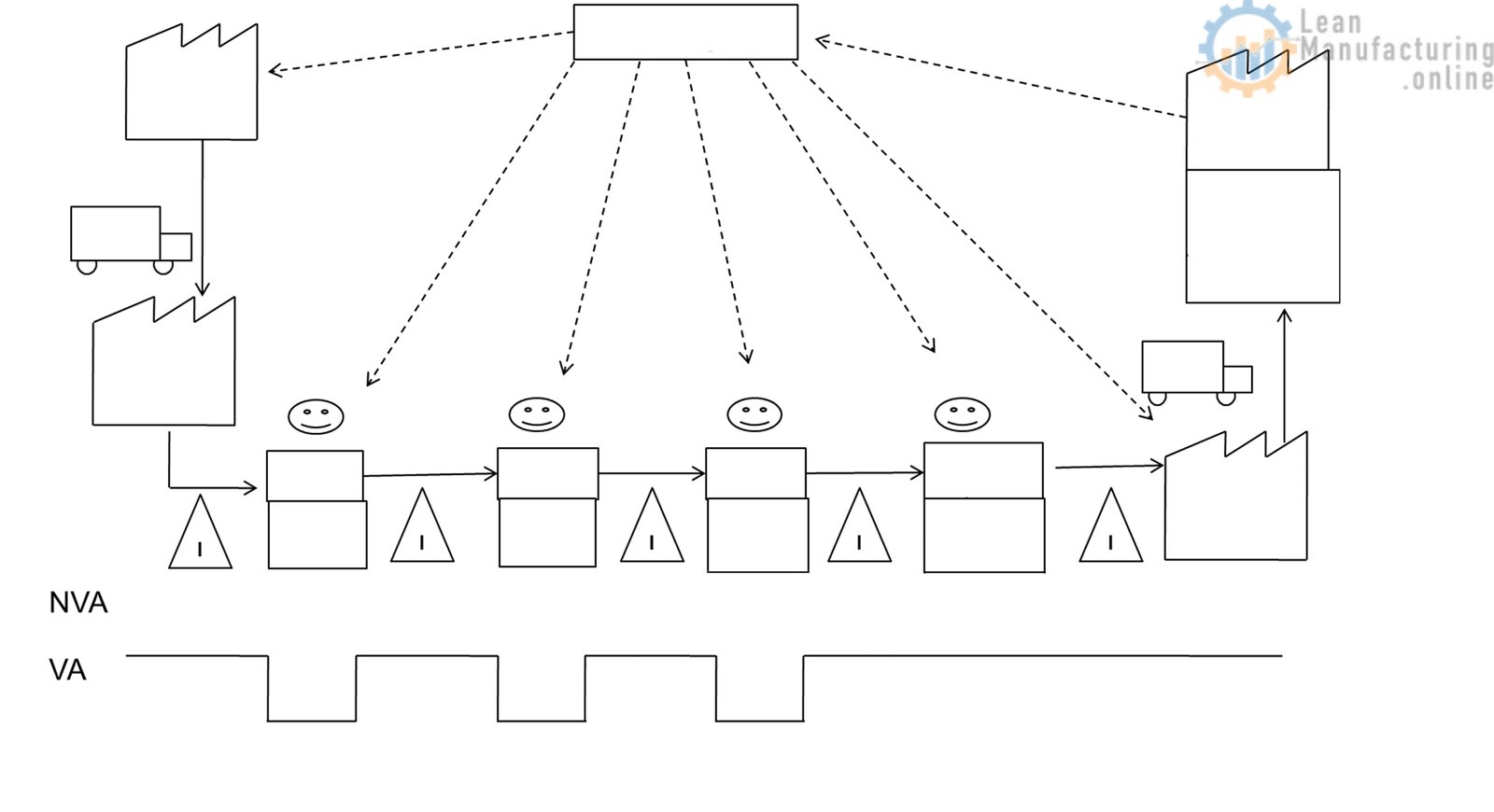

Read More »Value Stream Map

Tool that provides visualization and understanding of the flow of material and information as a product or service makes its way through the value stream and can be used to present both current state as well as future state vision. Current State It is a visual tool that shows all the…

Read More »