Production

Essential Product Performance Metrics for Business Growth

Learn how to leverage key product performance metrics to drive business success. From conversion rates to customer lifetime value, discover practical examples and insights to measure and improve your product's performance effectively.

Read More »Achieving Manufacturing Excellence: The Right First Time Approach

Discover how Right First Time (RFT) principles can revolutionize your manufacturing process by reducing defects and improving quality from the outset. Learn key strategies to enhance your RFT score and boost efficiency.

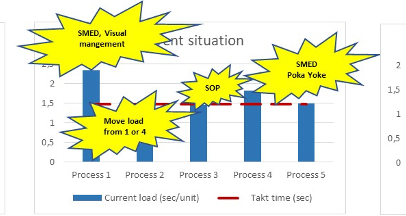

Read More »Workload balancing and a case in manual assembly

In this article, I will briefly run through the process of workload balancing; what is it, what does it do, and how do you do it? I will follow up that description with an actual case in a manual assembly process of a shutter used in an internet connector. It…

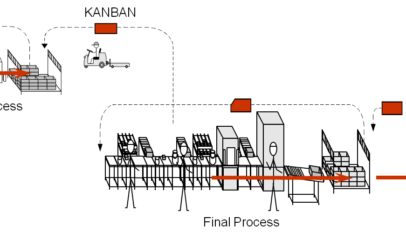

Read More »Production Systems: 10 things to consider when implementing a Pull System

Discover the key principles, pros, and cons of push and pull systems in supply chain management. Learn how to balance these approaches to optimize production, reduce waste, and meet customer demand effectively.

Read More »