Supply Chain

Supply Chain Management (SCM) and its relationship to TPM. Part 1

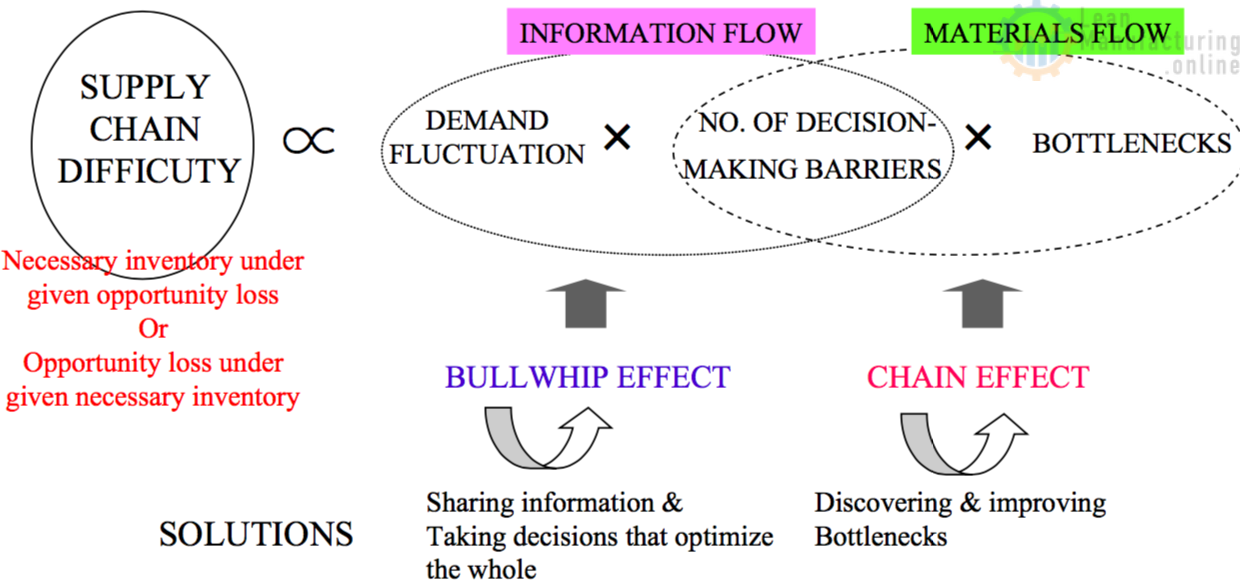

SECTION 1 WHY DO WE NEED SCM? SCM is now the accepted and ordinary business model, but … Making more the supply chain visible enables naturally us to reduce both lead times and costs SCM – THE ACCEPTED BUSINESS MODEL Since the late 70s, we have been in an era…

Read More »The 16 Big Losses and Related Costs

How does working patiently and persistently to eliminate the 16 Big Losses not only have the benefit of driving up OEEs, but also help greatly to drive down costs? If a plant has been working flat-out to meet demand, for example, with its operators doing overtime and holiday work, increasing…

Read More »Working on or near live electrical equipment parts

This Guidance Document describes rules and procedures for safe working with high voltage electrical equipment. It details operating procedures, Permit to Work and other safety documents, provisions for entry into High Voltage enclosures, safety precautions prior to working on conductors and tests required on equipment. SCOPE It is recommended that…

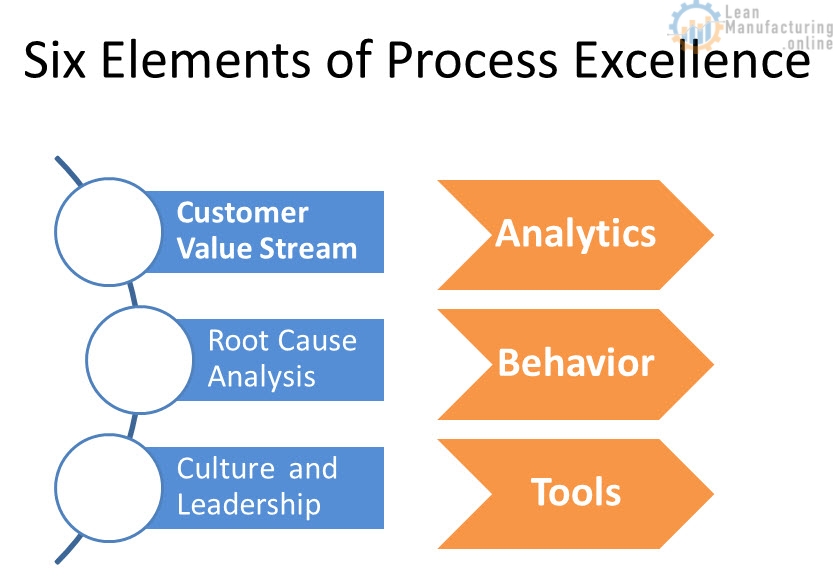

Read More »6 Elements of Process Excellence

First let’s review “what” is Process Excellence, or first three elements of the process: Customer Value Stream (CVS) processes that run flawlessly from one end to another; delivering value to the customer when they want to where they wanted to how they wanted with little or no waste. Root Cause…

Read More »