SECTION 1

WHY DO WE NEED SCM?

- SCM is now the accepted and ordinary business model, but …

- Making more the supply chain visible enables naturally us to reduce both lead times and costs

SCM – THE ACCEPTED BUSINESS MODEL

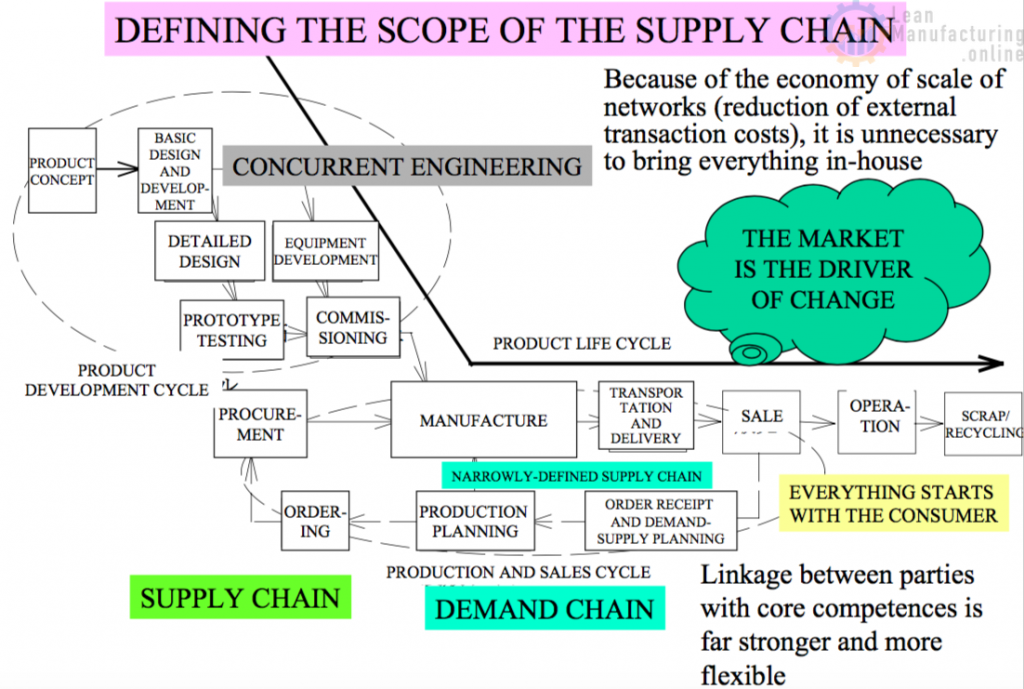

- Since the late 70s, we have been in an era of time competition as well as price and quality competition – using information technology (IT) as an enabler, we must increase the visibility of the entire supply chain and broaden the scope of information sharing

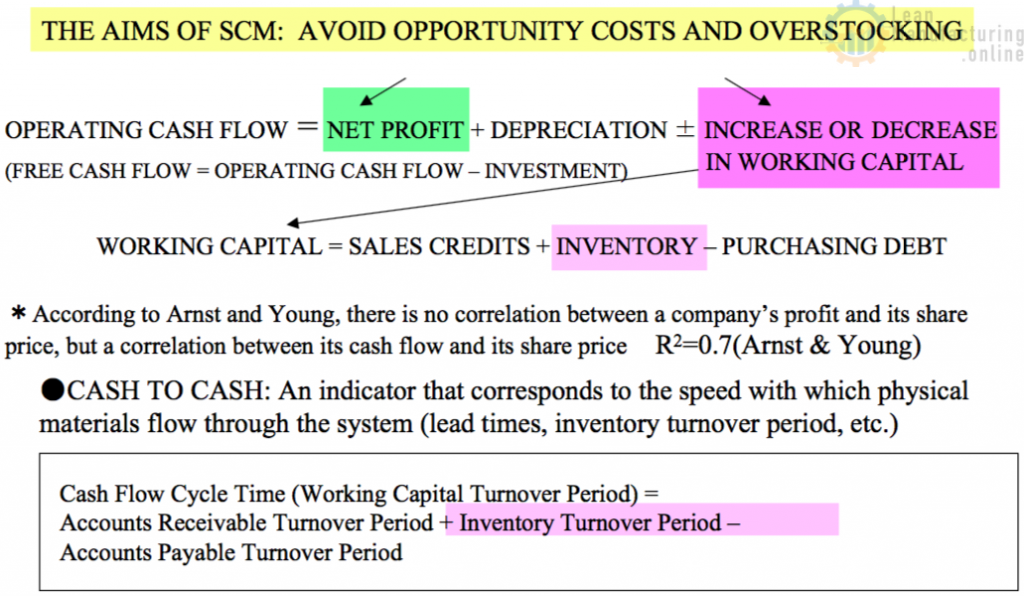

- Rapid responsiveness (instant awareness of market changes enabling us to brake or accelerate immediately while keeping efficiency) is the way to avoid high levels of dead stock and opportunity costs and is the key to improving cash flow

- 25% of a product’s sales price (omitting channel costs) comes from undiscovered interface costs within the supply chain

- The competence required for bringing in new added value is to make the entire supply chain visible through information sharing and tracking ability and optimize based on this

DEFINING THE SCOPE OF THE SUPPLY CHAIN

SCM AND CASH FLOW

CHANNEL COST ANALYSIS

THE MANUFACTURING SUPPLY CHAIN

SECTION 2

WHERE TO FOCUS IN SCM, AND WHERE TO STEER MANUFACTURING

- VARIOUS STYLES OF SCM

- THE ESSENCE OF SCM, AND WHERE TO FOCUS

- THE BULLWHIP EFFECT, THE RISK POOLING EFFECT, AND DESIGN FOR LOGISTICS (DFL)

- 3 DIRECTIONS FOR MANUFACTURING

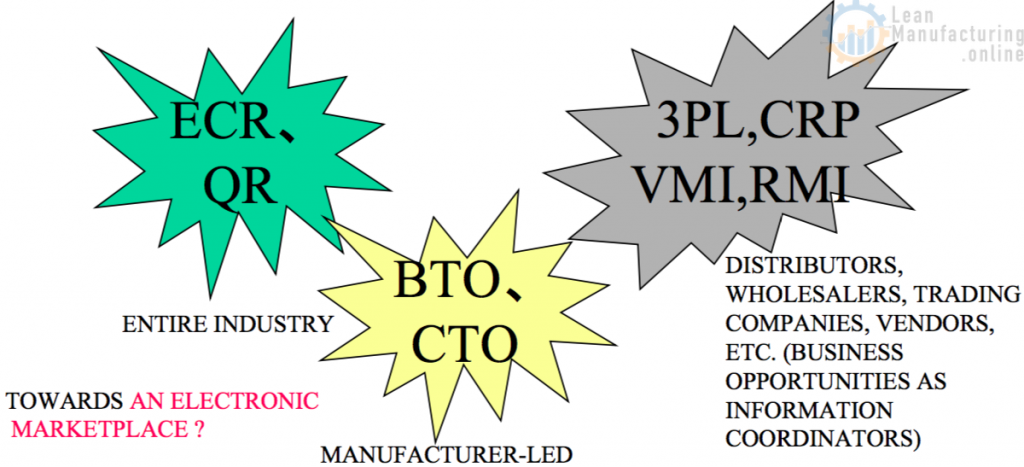

DIVERSIFIED PLAYERS OF SCM AND TERMINOLOGY SUPPORTING SCM

- ECR (Efficient Consumer Response)

- QR (Quick Response)

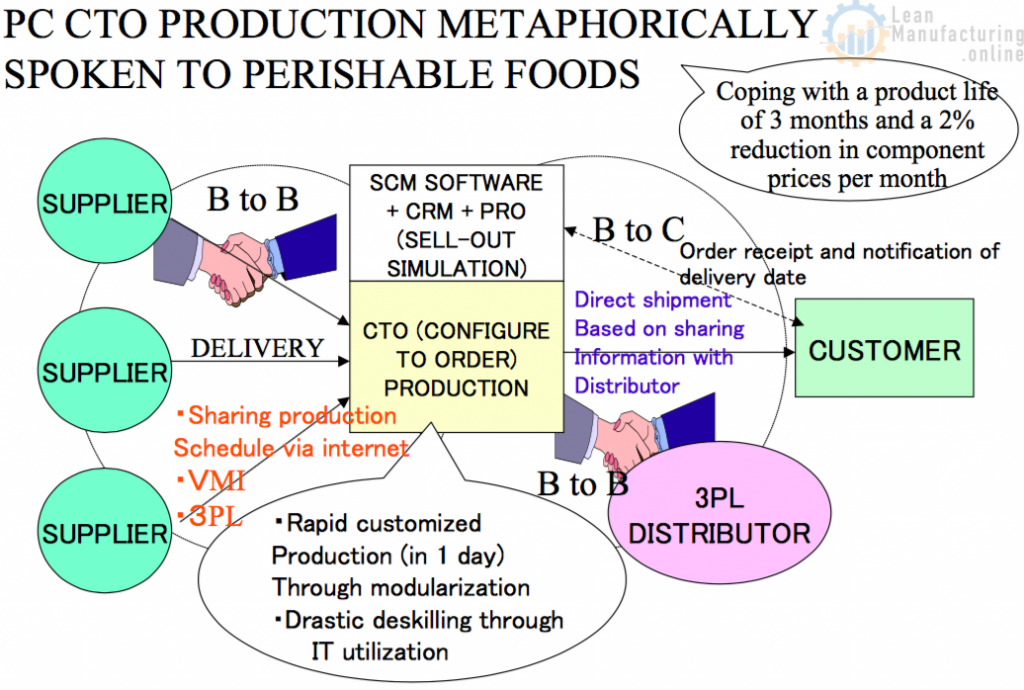

- BTO (Build To Order)

- CTO (Configure To Order)

- 3PL (3rd Party Logistics)

- CRP (Continuous Replenishment Program)

- VMI (Vendor Managed Inventory)

- RMI (Retailer -)

- CPFR (Collaborative Planning Forecast & Replenishment)

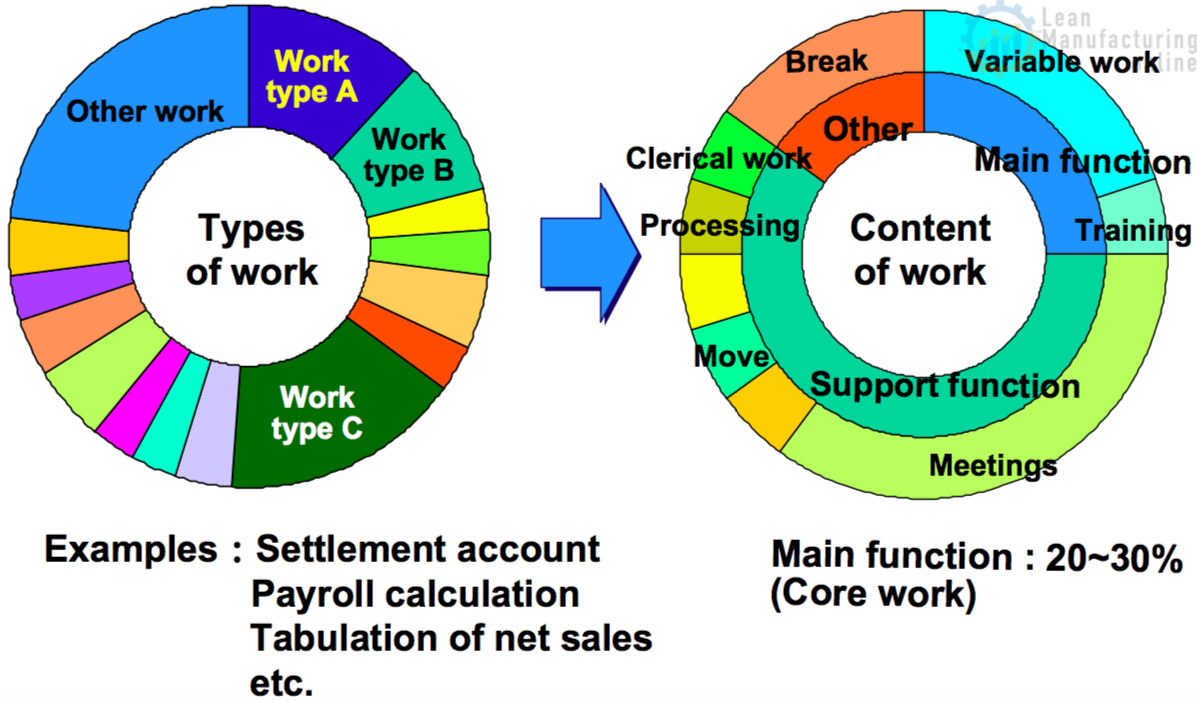

IMPROVING WORK QUALITY, SPEED AND EFFICIENCY, AND THE AIMS OF SCM

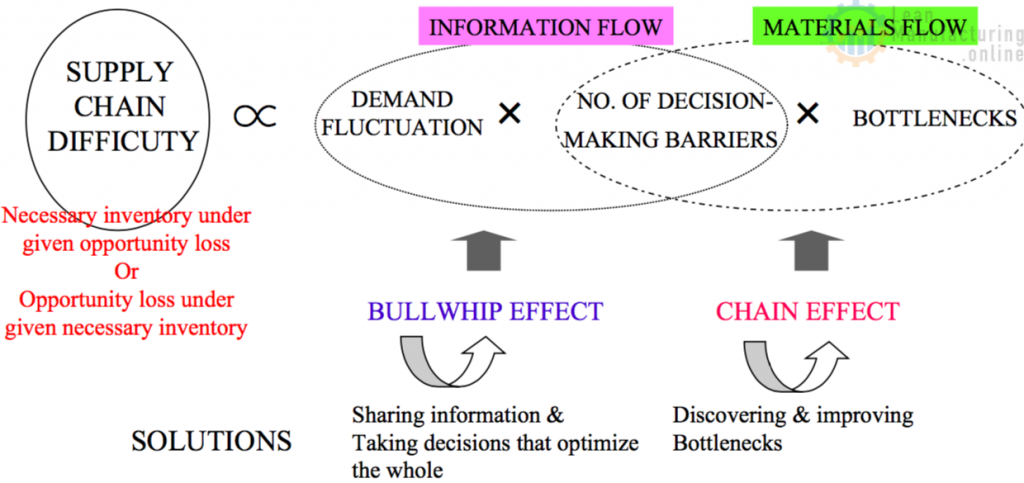

- Information-sharing – not just grasping actual demand accurately, but also eliminating the bullwhip effect through effective 2-way communication

- Improving the accuracy of demand forecasting and reducing safety stocks through the risk-pooling effect

- Enjoying the benefits of DFL (design for logistics) strategies

- Reduce costs by designing for transportability

- Shorten lead times by making the replenishment processes concurrent

- Respond to the need for mass customization by postponement strategy (re-sequencing, parts standardization, modularization, etc.)

- New styles of distribution partnerships

THE EFFECT OF DECOUPLING DEMAND DEPENDENCE (THE AMPLIFICATION EFFECT OF DEMAND VARIATION)

The 3 factors that increase the difficulty of SCM, with their effects and solutions: Strengthening the supply chain and eliminating the bullwhip and chain effects

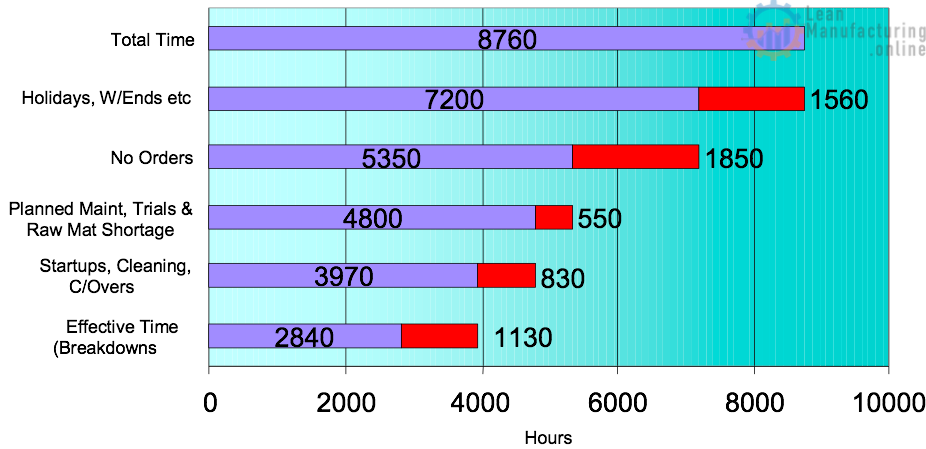

ONLY A TINY PART OF CUSTOMER LEAD TIMES ACTUALLY ADD VALUE – MOST IS WAITING OR STOPPING OR LOST AWAY

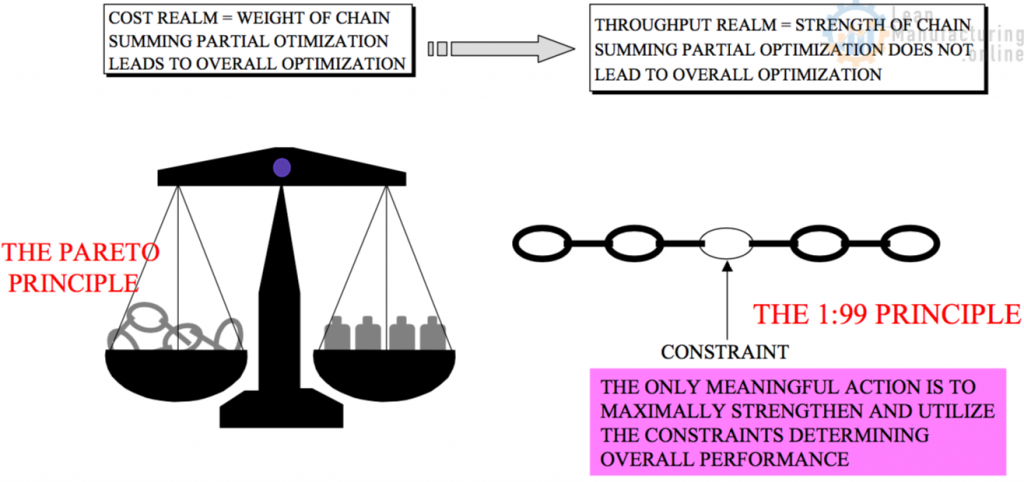

THE COST REALM AND THE THROUGHPUT REALM: OVERALL OPTIMIZATION BY MEANS OF THE CHAIN ANALOGY (LESSON BY TOC)

TOWARDS CPFR TYPE

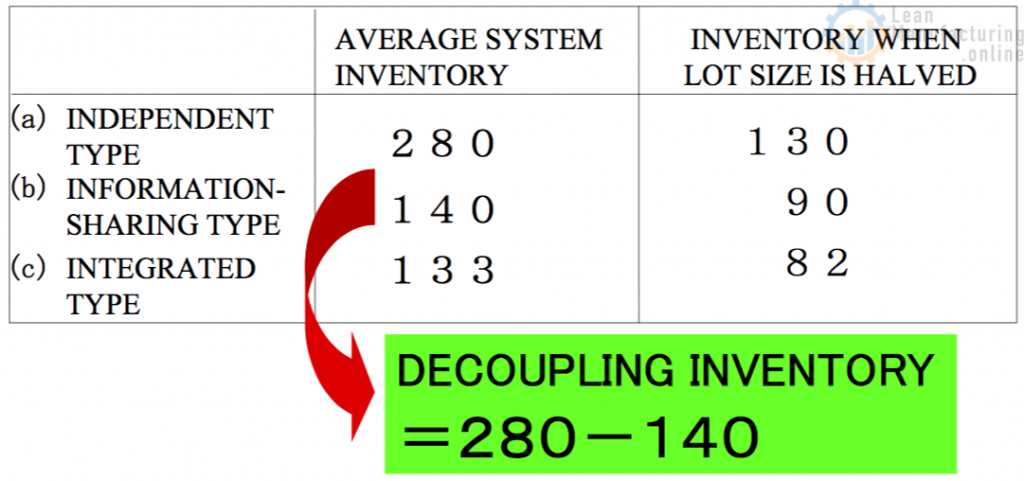

2 STEP-MODEL ON THE DIFFERENCE OF SHARING INFORMATION

- THE BENEFITS OF SHARING INFORMATION (FLOW OF INFORMATION)

- WHAT ARE THE BOTTLENECKS THAT DETERMINE OVERALL SPEED? (FLOW OF MATERIALS: LEAD TIMES AND CYCLE TIMES)

COMPARISON OF NECESSARY STOCKS FOR the SAME LEVEL OF SERVICE

PC CTO PRODUCTION METAPHORICALLY SPOKEN TO PERISHABLE FOODS

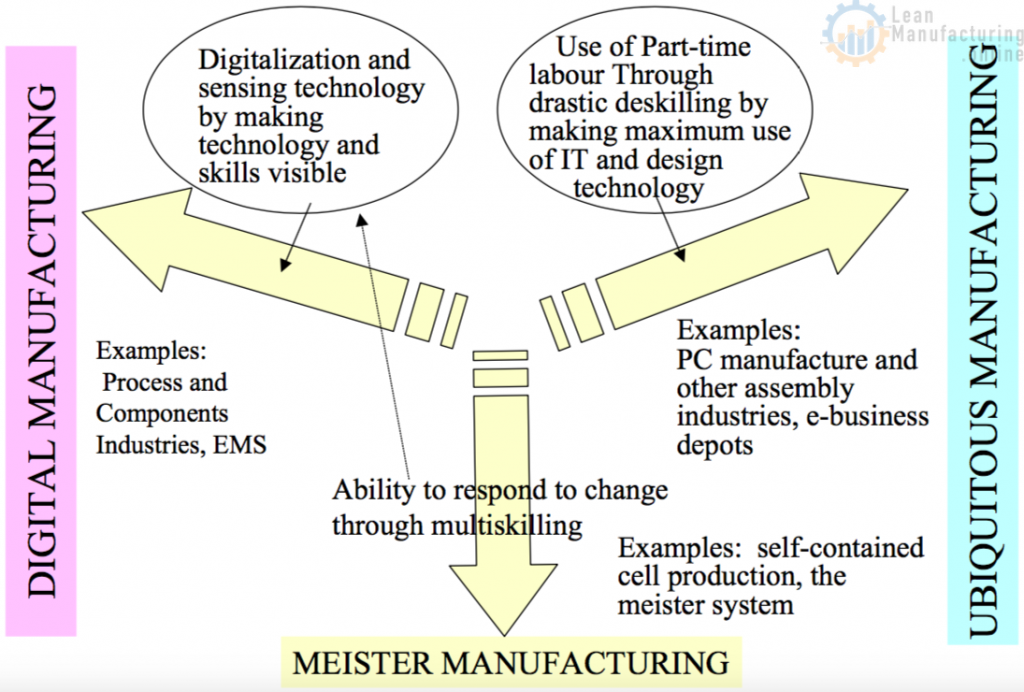

THE TRIPOLAR EVOLUTION OF MANUFACTURING THROUGH THE USE OF IT AND VALUE CHAINS

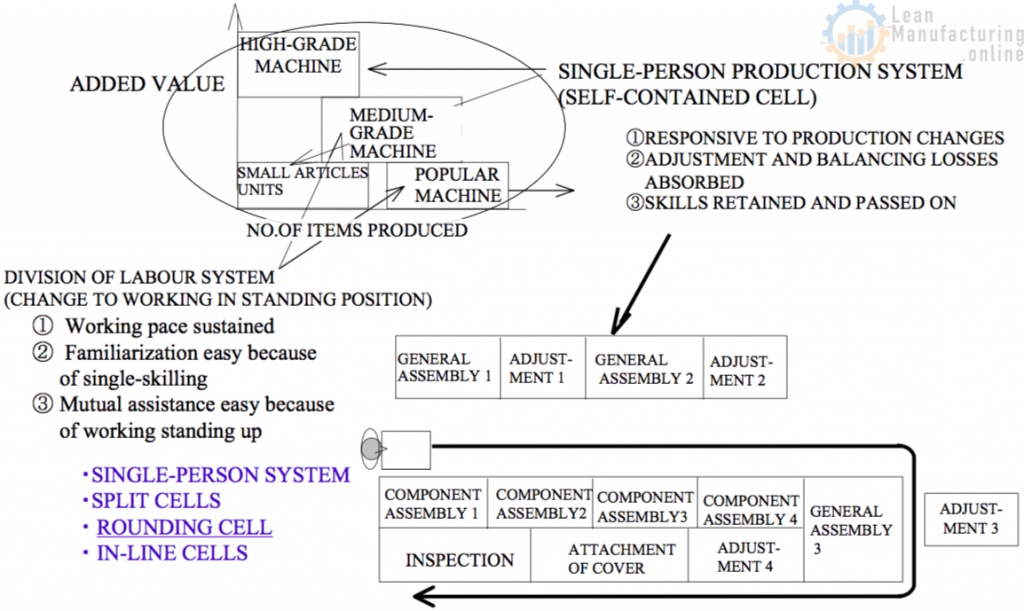

THE SELF-CONTAINED CELL MANUFACTURING SYSTEM

DFL (DESIGN FOR LOGISTICS)

THE DFX CONCEPT, Which includes redesign of the business model as well as product design: mass customization, speed, greater efficiency and environmental response.

- Product design that takes the entire product life cycle into account

- Design that takes packing into account, size standardization, and source marking

- Lead-time reduction through synchronization of the replenishment process

- Simultaneous, parallel component production

- Responding to the need for mass customization using the Postponement strategy

- Re-sequencing (making customization a later process), parts commoditization, modularization, deskilling of processing through f countermeasures like foolproof by IT utilization

- New types of distribution partnerships

- Moving from TC and cross-docking to area joint distribution centres; joint distribution systems with information-sharing as a prerequisite; elimination of incoming inspection