OPL

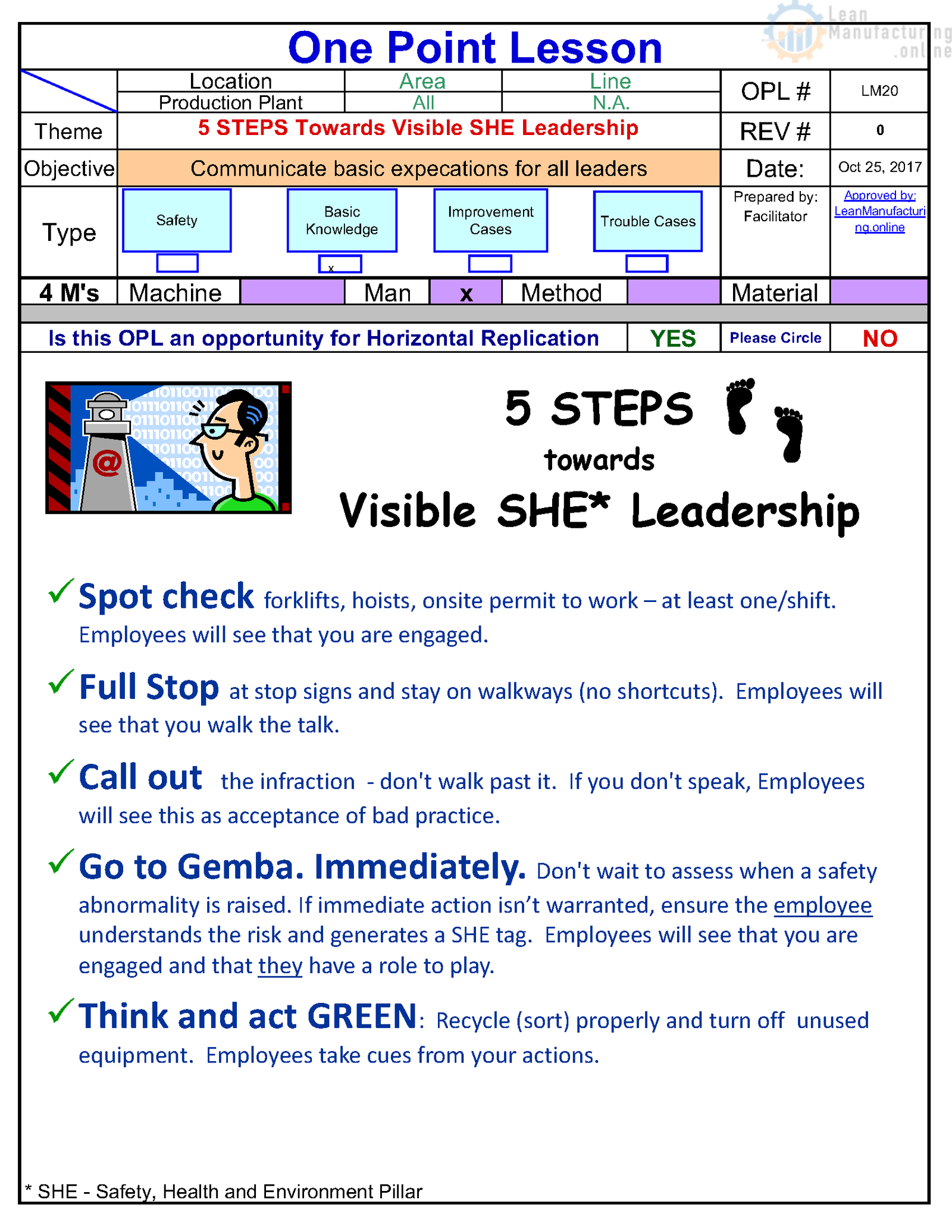

The five steps towards visible Health and Safety Leadership

One Point Lessons are short visual presentations on a single point that sharpen job-related knowledge, easily share important information just-in-time Improve skills by communicating information about specific problems and improvements Spot check forklifts, hoists, and onsite permit to work – at least one/shift. Employees will see that you are engaged.…

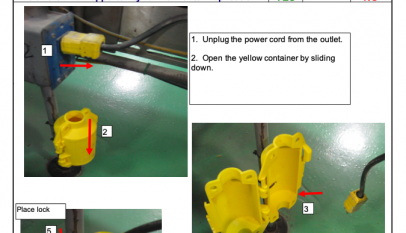

Read More »OPL – Safely locking out the tape machine or any other equipment with plug

Have a mobile piece of equipment on production floor that is not hardwired? Usually these types of equipment don’t have lockable switch but power source need to LOTO to work safely. Simply attach Electrical Plug Cover Lockout to frame of the equipment, so it would be there when LOTO will…

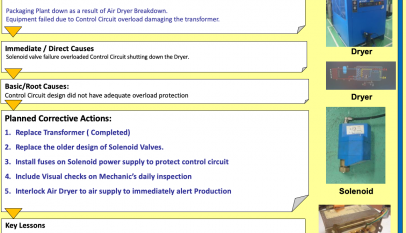

Read More »Lessons Learnt as a communication tool

Another great tool to create short but meaningful communication is Lessons Learnt. It can be used to communicate Safety, Quality or Productivity issues to all Team Members. Goal is to explain what happened and how to avoid it from happening in the future. Lessons Learnt Principles applied are to: Take…

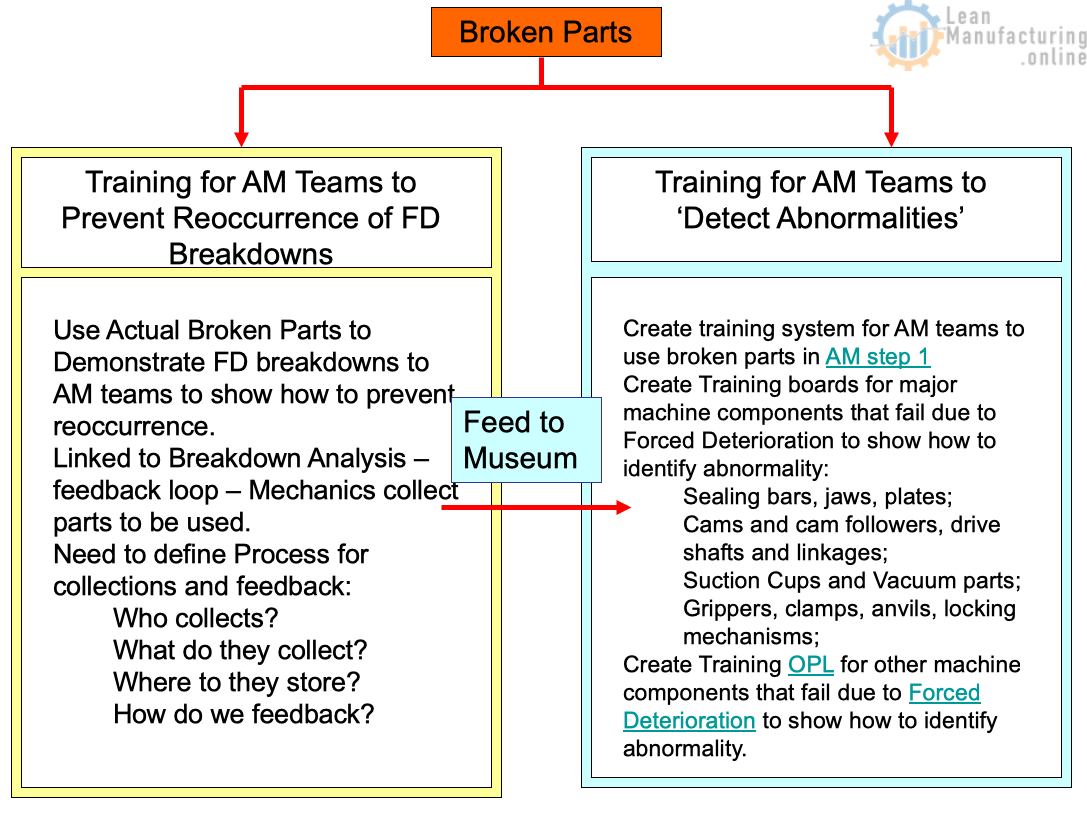

Read More »Broken Parts Museum – Analyzing and Preventing Breakdowns due to Forced Deterioration

5 Why Analysis Autonomous Maintenance Blog OPL Root Cause Analysis Training World Class Manufacturing

Collecting broken or worn machine parts for later analysis will help to understand root cause of failures, as well as can assist with training AM team members. Training for AM Teams to Prevent Reoccurrence of Forced Deterioration Breakdowns Use Actual Broken Parts to Demonstrate FD breakdowns to AM teams to…

Read More »