Tools

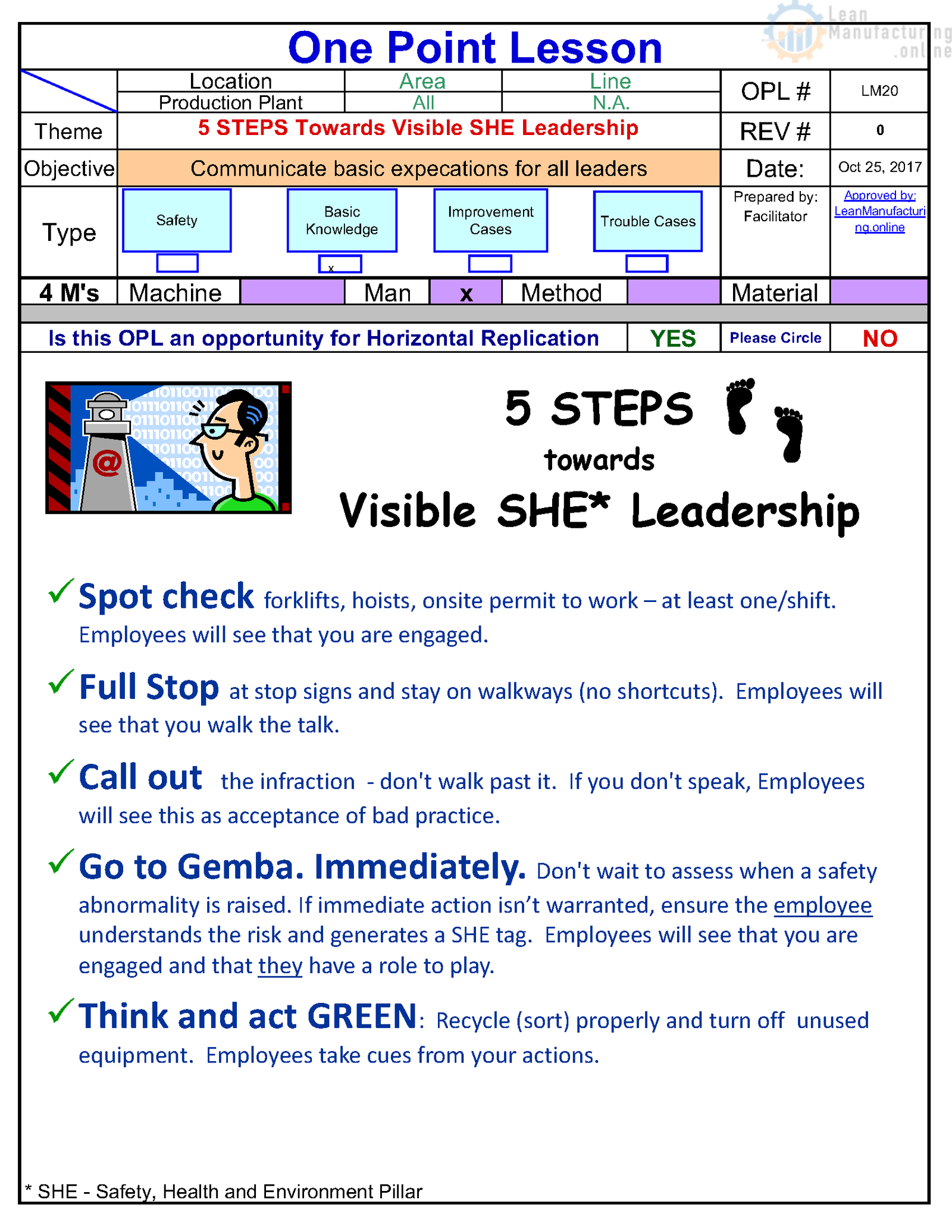

The five steps towards visible Health and Safety Leadership

One Point Lessons are short visual presentations on a single point that sharpen job-related knowledge, easily share important information just-in-time Improve skills by communicating information about specific problems and improvements Spot check forklifts, hoists, and onsite permit to work – at least one/shift. Employees will see that you are engaged.…

Read More »Steps to create Value Stream Mapping

A Value Stream Map is… A tool that helps visualize and understand the flow of material and information as a product or service makes its way through the value stream: A high-level map that visually presents the flow of a product or service from supplier to customer can be used…

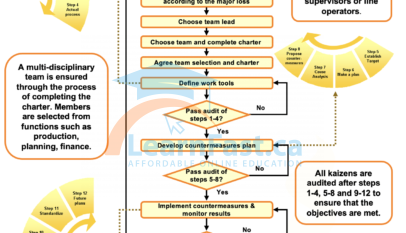

Read More »Kaizen Process

Kaizen is the critical tool for executing Continuous Improvement.

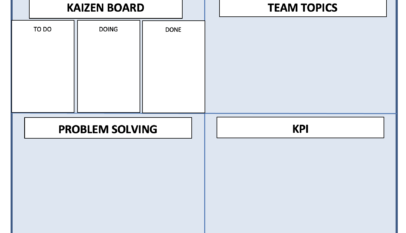

Read More »Kaizen Boards

Kaizen is not about spending more money: we have the current resource and we find a way how to use them more efficiently.

Read More »