Tools

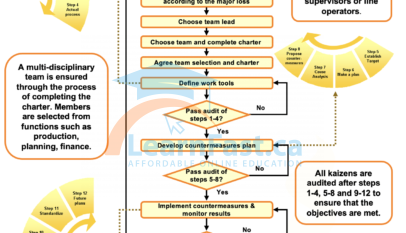

12-Step Kaizen Story

The Key Tool for Executing Continuous Improvement 12-Step Kaizen is a Better Defined CAP-Do Check Identify where the losses are Justify the subject selection by stratifying the data Understand the process and equipment Grasp the actual situation (Identify the Phenomenon) Establish the objective Establish a Work Plan Analyze Determine Root…

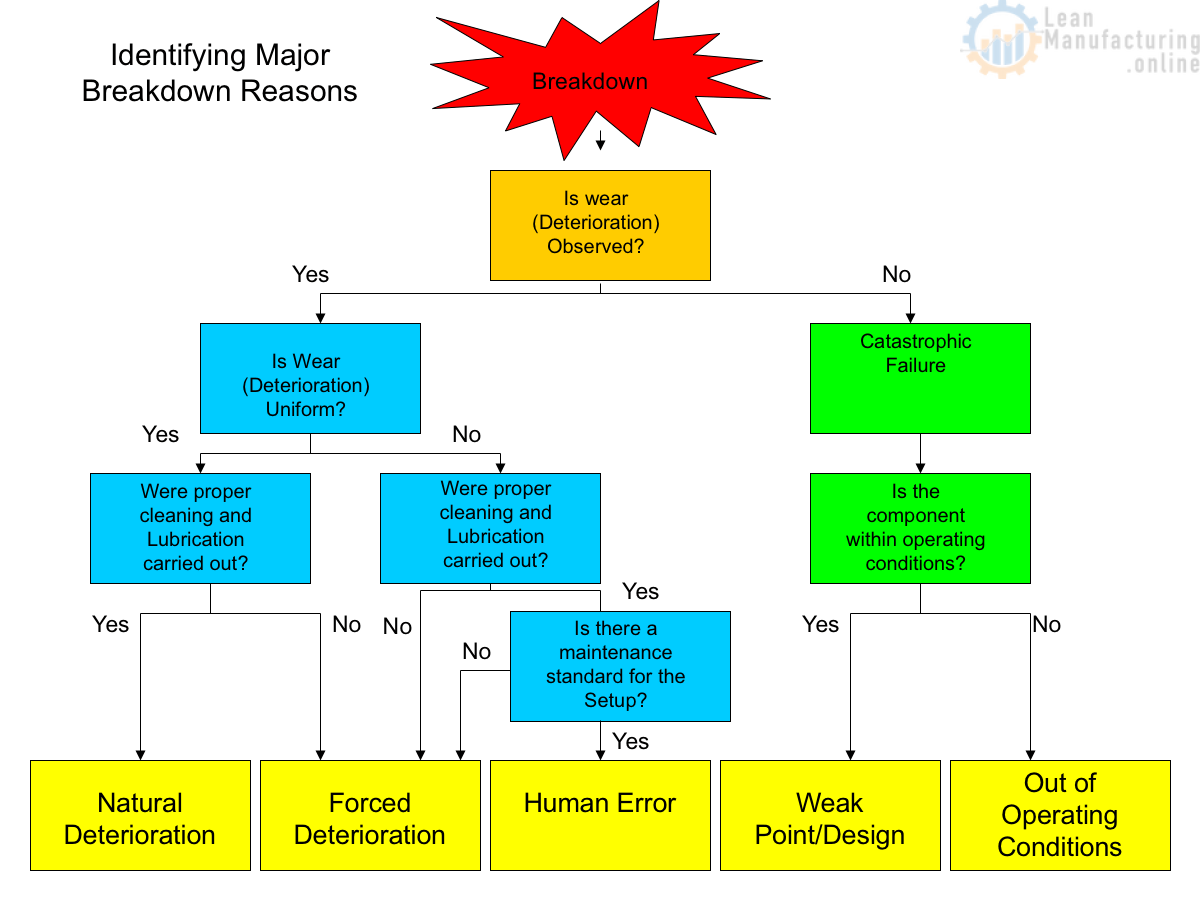

Read More »Breakdown analysis. Case Study

Let’s review an example of Breakdown Analysis of the failure that occurred in real life in the material handling department of a manufacturing factory: Step 1. 5W+1H and Phenomenon Summary Start your Breakdown analysis by answering six simple questions: 5 whys and 1 how Phenomenon Summary Use all answers from…

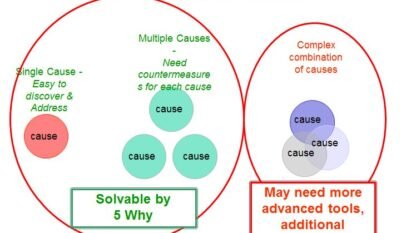

Read More »5 WHY Analysis, a TPM Tool for Root Cause Analysis (RCA)

Section 1 5 WHY Process Causes of Losses are Often Complicated: Common Failure scenario: 1. Management system breakdown2. Failure to implement countermeasures3. Premature equipment failure4. Employees fail to follow the procedure5. Failure to ID & Respond6. Large Loss Results 5 Why Analysis is Proactive Addresses the Underlying Causes of Losses:…

Read More »Poka-Yoke

What is Poka-Yoke? Developed by Toyota Motors as a tool to achieve Zero Defects Originally called Baka Yoke (idiot proof) but recognized that this label could offend workers so changed to Poka-Yoke (Mistake Proofing) One serious obstacle to extending equipment life is the unexpected failure that occurs as a result…

Read More »