Autonomous Maintenance

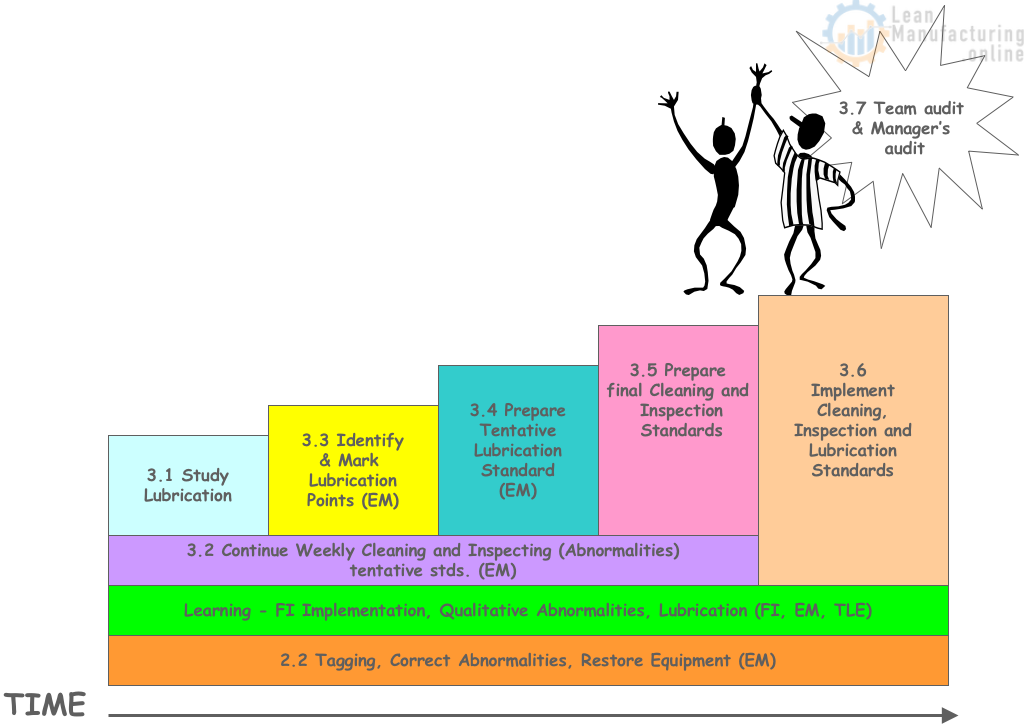

Autonomous Maintenance Step 3

Objectives What is Autonomous Maintenance Step 3? What are some of the main activities? Prerequisites AM Introduction AM Preparation for F-Tags and OPL’s AM Step 0 (5S and Zero Energy State) AM Step 1 and AM Step 2 Step 1: Learning Defect ID, Basic 5W-1H Clean F-tag Abnormalities 80%…

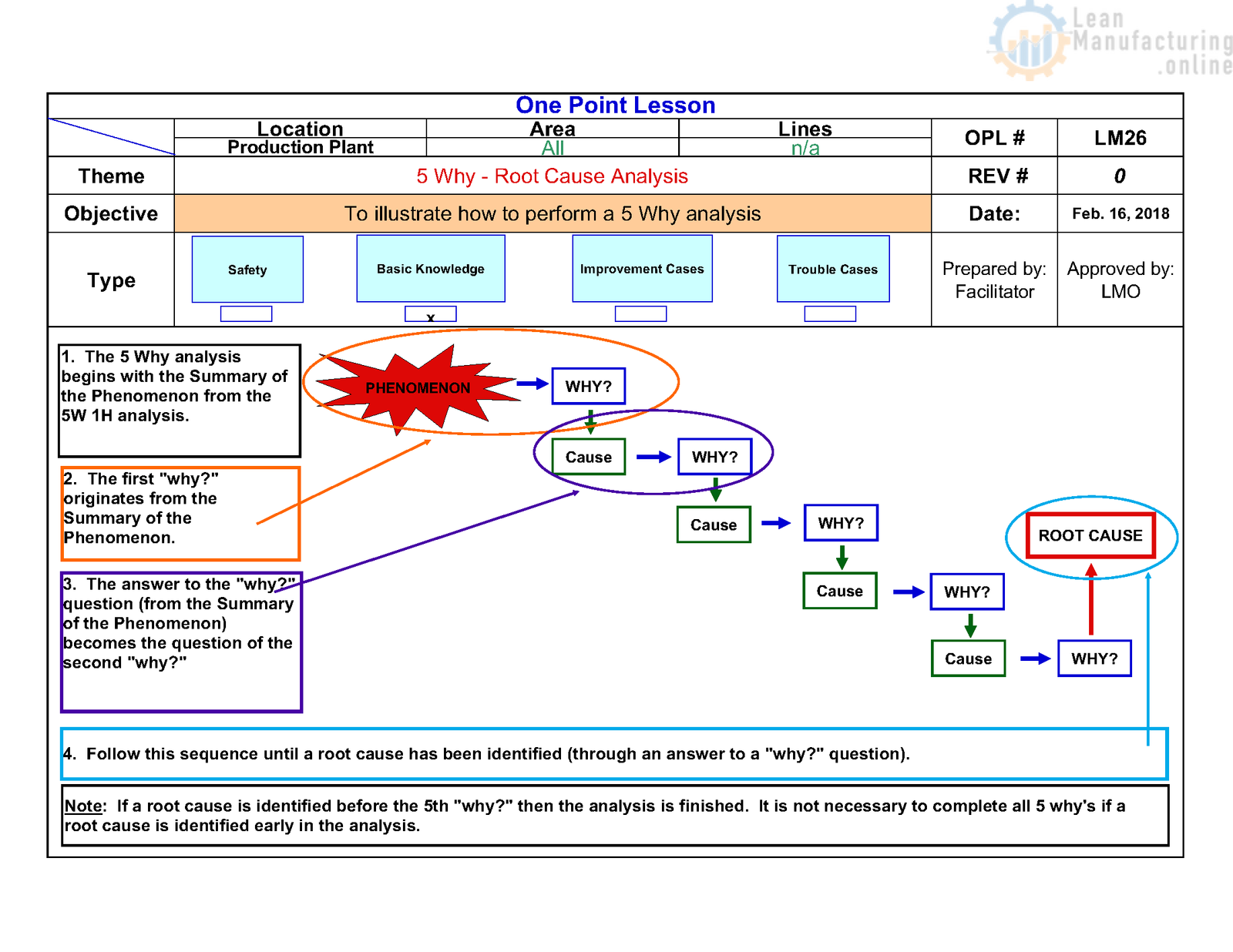

Read More »5 Why Root Cause Analysis (RCA) – One Point Lesson (OPL)

5 WHY Analysis is the key tool used to determine ROOT CAUSES for the Phenomenon identified in theCHECK Phase of CAP-Do. The 5 Why analysis begins with the Summary of the Phenomenon from the 5W 1H analysis. The first “why?” originates from the Summary of the Phenomenon. The answer to…

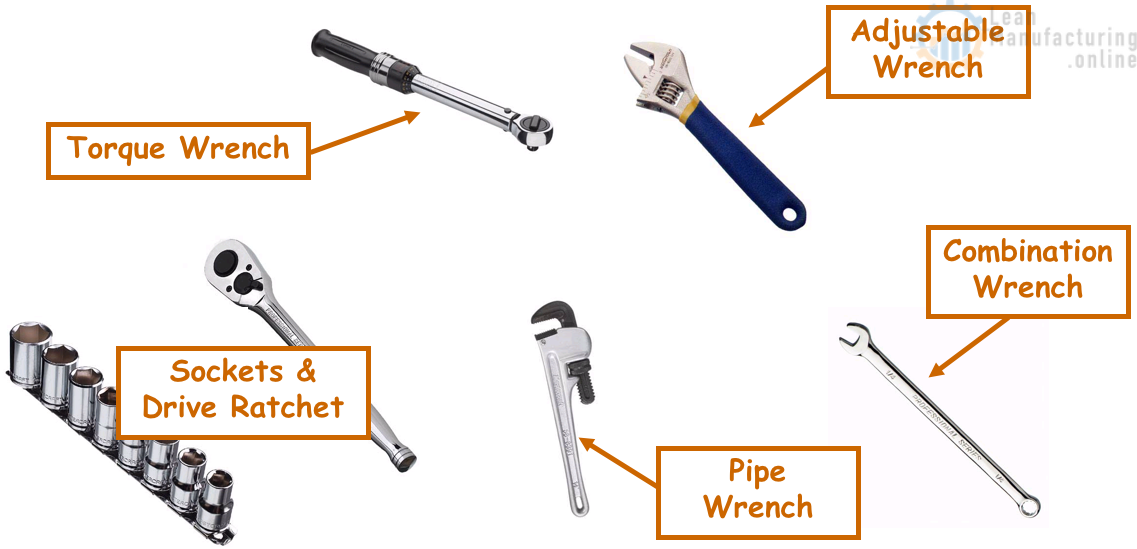

Read More »Basic Hand Tools Safety Module

Training Objectives: Identify basic hand tools used for routine maintenance activities. Provide examples of tool abnormalities to support inspection activities. Demonstrate proper and safe use of hand tools. Hand Tools Held in the “hand” and powered by the person using them Important to be able to identify them Know the…

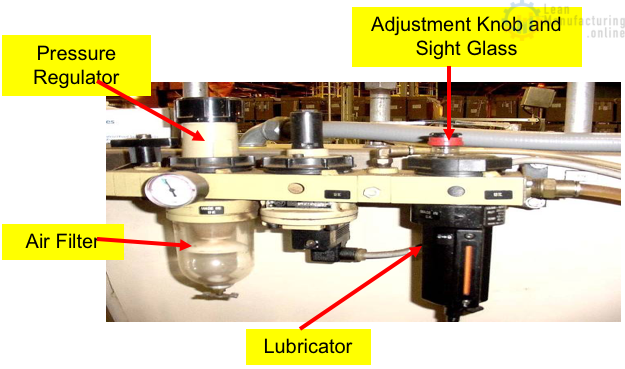

Read More »Autonomous Maintenance. Pneumatics training module for operators

Basic Pneumatic – Introduction Introduction Overview: Pneumatics is about using compressed air “to make something happen.” The word Pneu is Greek meaning wind, breath or air. Pneumatic equipment refers to those items that use or are driven by air. Air has no definite shape or volume; it takes on the…

Read More »