Training Objectives:

- Identify basic hand tools used for routine maintenance activities.

- Provide examples of tool abnormalities to support inspection activities.

- Demonstrate proper and safe use of hand tools.

Hand Tools

- Held in the “hand” and powered by the person using them

- Important to be able to identify them

- Know the uses and misuses

Hand Tool Safety

According to Accident Facts, hand tools are involved in 6% of all compensated work injuries. This figure increases to 14% for non-compensated injuries.

The average cost of a hand tool injury is listed as US$1250.

This is only counting the direct costs and not the indirect injury costs (i.e. lost production).

The primary hazards encountered when using hand tools include:

- striking or contacting part of the body with the tool

- striking the body with the work piece

- projectiles flying off the tool or workpiece

The most common injuries from the use of hand tools are:

- Laceration or cut from a knife blade, saw, or other tool with a sharp surface or jagged edge.

- Contusions, or bruises from striking the fingers with the tool.

- Foreign objects in eyes.

Common Causes of Injuries:

- Not wearing appropriate PPE.

- Using the wrong tool for the work to be performed.

- Using the tool improperly.

- Using defective tools.

- Failure to inspect the tool before use.

- Improper storage or transportation of the tool.

Tool Defects:

All tools should be inspected for hazardous defects before each use.

Immediately remove from service any tools that are not in proper working condition.

Most common hazardous tool defects include:

- Mushroomed heads on chisels or punches

- Dull knives

- Loose handles

- Sprung wrench heads

- Bent screwdriver bits

- Worn screwdriver tips

Always keep your tools clean.

- Oil can cause the tool to slip off an object or out of your hands.

- Dirt and grime can impair the tool’s work, requiring more pressure.

Keep tools where they belong

- Carry tools in a toolbox or tool belt, especially those with sharp points or edges.

Pass a tool to another person by the handle;

- never toss it to them

Check for secure footing.

Handle a tool in such a way that, if a slip occurs, the direction of force will be away from your body.

Have plenty of finger clearance.

Never hold the workpiece in your hand, if the tool slips it will stab the palm of your hand.

Screwdrivers:

Used for one purpose only:

tightening and removing threaded fasteners.

- Robertson (square)

- Philips (cross)

- Flat

Proper Use:

- Select the right screwdriver

- Select the correct size of screwdriver

- Check screwdrivers for worn or bent tips

- Check screwdriver for handle damage & bent shafts

The screwdriver width and

thickness should match the

fastener width and thickness.

Use Guidelines:

Use Guidelines:

- Hold the screwdriver parallel with the screw

- Use one hand to apply force

- Use the other hand to help guide the screwdriver and keep it straight

Common Misuses:

- Do not use as a pry bar, scraper, chisel or punch

- Do not use a flat-tipped screwdriver on a Phillips-head screw

- Do not use a damaged screwdriver on any fastener

Nut Drivers:

- Safer to use than a screwdriver

- Used for small diameter fasteners where torque is not a factor

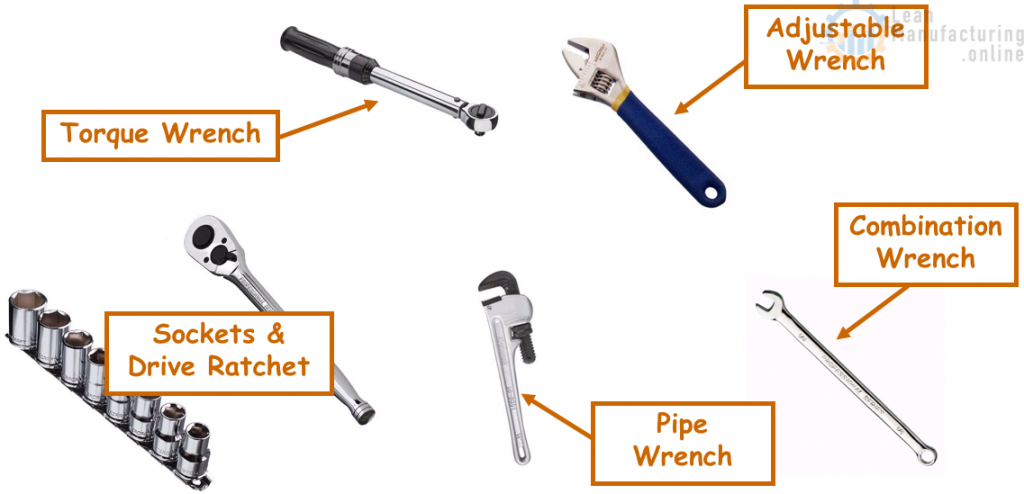

Wrenches:

Due to the wide variety of threaded fasteners and applications, you have an assortment of different styles:

Using Wrenches:

Verify correct size of wrench needed by fitting it onto the fastener head – Is it SAE or Metric ?

Check all wrench areas that contact fastener for damage and worn sides.

Ensure wrench is flush with fastener.

Where ever possible, use a socket or box-end wrench instead of an adjustable or open-ended wrench:

- they are generally easier to control, are more convenient;

- they completely encircle the nut, bolt or fitting and grip it at all corners as opposed to two corners gripped by an open end wrench;

- thus, they are less likely to damage a bolt or nut;

- they give great flexibility in hard-to-reach places;

- they will not slip off laterally;

- they eliminate the dangers of sprung jaws.

Wrenches should always be pulled and not pushed

- Pushing a wrench can cause a loss of control if there is a sudden release of pressure;

- If it slips, your hand may hit whatever is ahead of it;

- When possible, use both hands to hold and guide the wrench.

A short, steady pull should be used rather than quick, jerky motions.

Never hammer or strike a wrench!

A piece of pipe or “cheater” slipped over the wrench handle must not be used to give added leverage

This can strain a wrench to the breaking point.

The handle of every wrench is designed to be long enough for the maximum allowable safe pressure.

Combination Wrench:

- Most common type

- Versatile for “all-around” work

- Use box end to break fastener free or to snug it up tight

- Use open end to remove or tighten faster

Hex Head Wrenches:

Used to tighten and loosen recessed heads on set screws and cap screws.