Early Equipment Management

Equipment Suppliers Approach

Objective and Importance Understand different methodologies to manage our equipment suppliers Understand how can we put our equipment suppliers in our current management program Quick overview about Materials Suppliers Avoid delays and “surprises” related to suppliers Closer relationships with our suppliers How to put our suppliers in the innovation funnel?…

Read More »Early Equipment Management Project Checklist

Every successful project must have a checklist of activities. Please review our version off EEM checklist: EEM Step: EEM ACTIVITY 1 EEM Project Planning & Definition 1a Project Brief/Charter Evaluation Fully accepted Project Brief or Contract Set-up first EEM time-table 1b Project Type Recognition Fully Understanding and documentation of the…

Read More »Harmonized methodology of Early Product Management and Early Equipment Management

Considerations Steps act as guidelines for the activities to be done; They are located in the correct moment of the project; However, you don’t need to reshape all your Early Management in place; The idea is to: Add good ideas to your Early Management process; Review some activities importance; Review…

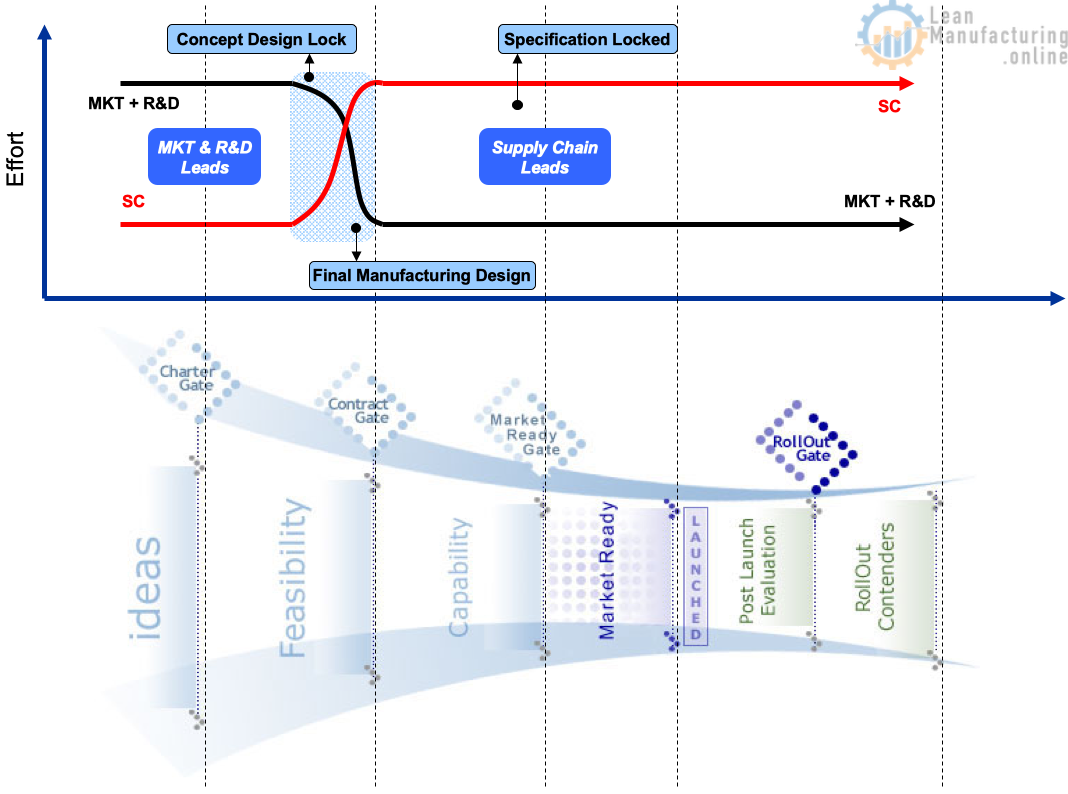

Read More »Innovation Project Management Funnel

Ideas All product developments start with IDEAS! First Ideas & Concepts Consumer Researches Consumer Benefits Consumer & Customer Complaints Inputs Opportunities Technology Scan First Impacts – all Company Financial Benefits Feasibility Marketing (MKT): Just one concept – finalize concept All areas start to develop their work Research & Development (R&D): Develop:…

Read More »