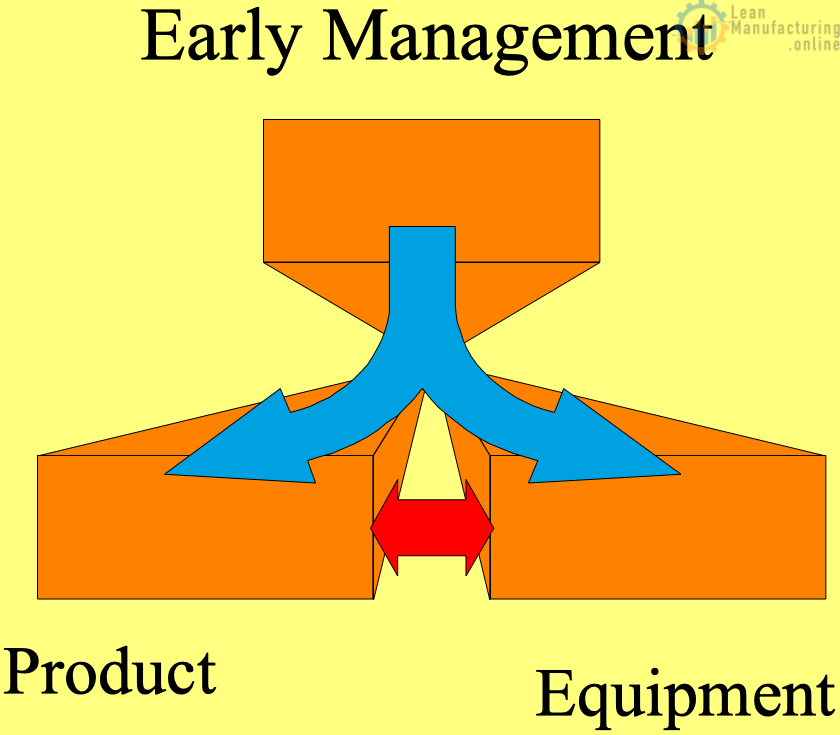

Early Equipment Management

Early Equipment Management – Launching Costs

The effect of the major losses during a start up Launching Costs = Category “A” + Category “B” Launching Costs: Operating Losses-Category “A” Components of Category “A”: Costs per shift Depreciation cost per shift; Labor cost per shift; Utility cost per shift; Maintenance cost per shift. Calculation of Category “A”…

Read More »Industrial Engineering – Continuous Improvement

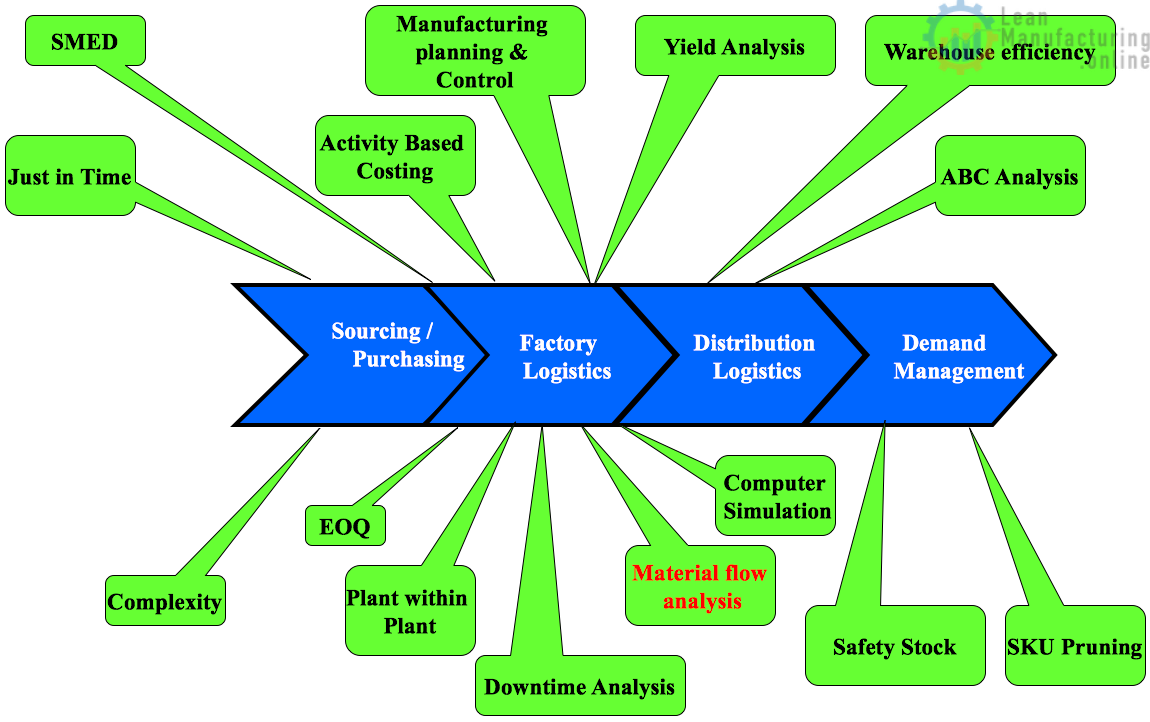

Engineering management is a discipline that combines technical expertise with business acumen. Engineering managers are responsible for overseeing projects, managing teams, and ensuring that projects are completed on time, within budget, and to the required quality standards.

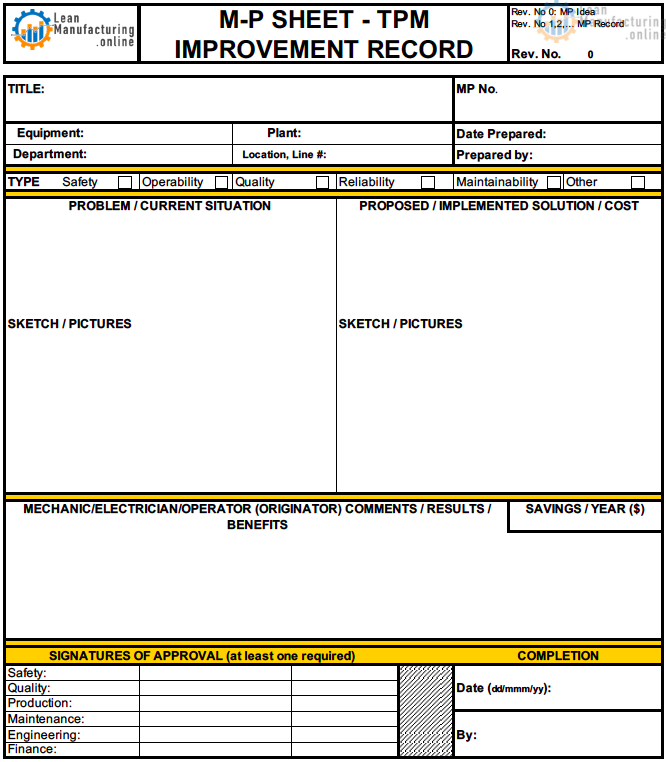

Read More »M-P sheet (EEM) free template download

The use of the latest maintenance data and technology when planning or building new equipment to promote greater reliability, maintainability, economy, operability and safety while minimizing maintenance costs and deterioration related loss. We offer free downloadable template in pdf format, to download, please click here Some of Early Equipment Management…

Read More »Best Practice Dosing for Savoury Dehydrated Products. Part 3

4. Dosing Accuracy This chapter covers required and actual dosing performance. Dosing accuracy needs to meet quality requirements, legal requirements and factory costs. 4.1. Quality and Quantity guarantee The target weight distribution should meet quality and legal requirements in the most economic fashion (no systematic overfill, no packages to re-empty…

Read More »