Early Equipment Management

Early Equipment Management – Attaining business objectives by using equipment efficiently

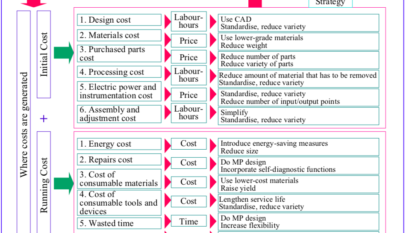

The ability to respond nimbly to fluctuations in production requirements – in other words, high flexibility – is the key to maximizing LCP.

Read More »Making use of information on problems arising during Early Product Management

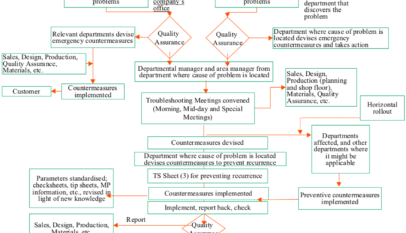

Despite all efforts made to build in quality and factory-friendliness at the design stage, problems may well arise, inside or outside the company, from any point from prototyping through volume production. When this happens, it is important to establish the facts, investigate the causes, send prompt feedback to the preceding…

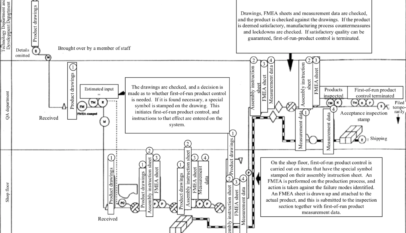

Read More »Building in quality through control of first-of-run products

The system ensures that quality is built into the product by making it impossible for any product to be shipped until the production department has carried out a process FMEA, implemented and checked countermeasures, and locked them down.

Read More »Early Product Management – Objective and Basic Approach

The ultimate aim of an Early Product Management system is to ensure that all problems are detected and dealt with early in the product development process, totally eliminating the need for changes from the prototyping stage onwards.

Read More »