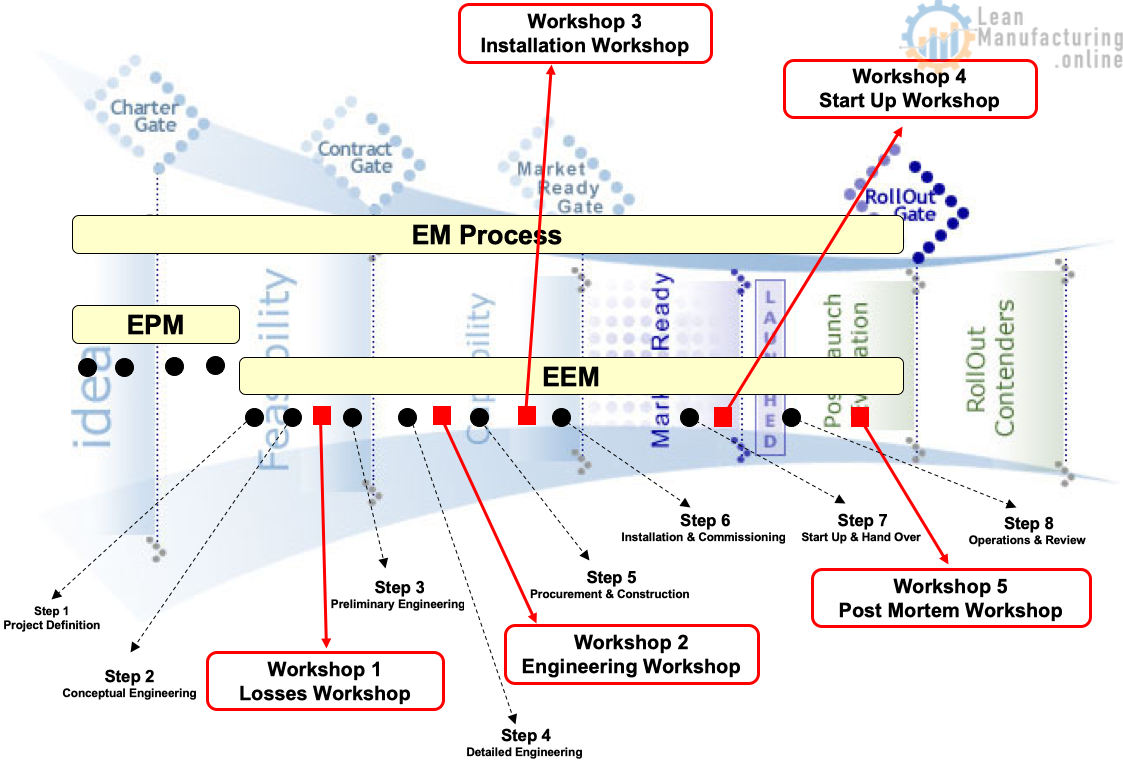

Early Equipment Management

Main Elements Guide for the 8 Key Steps of EEM

MAIN STEP ELEMENTS FOR YOUR PROJECT Step 1: EEM Project Definition Write and sign SCOPE Project kick-off with project TEAM Define KPI’s and Targets based on the project charter Ensure stakeholder expectations are clear. Conduct a DESIGN REVIEW with a checklist to include added parameters to the conceptual design. Required…

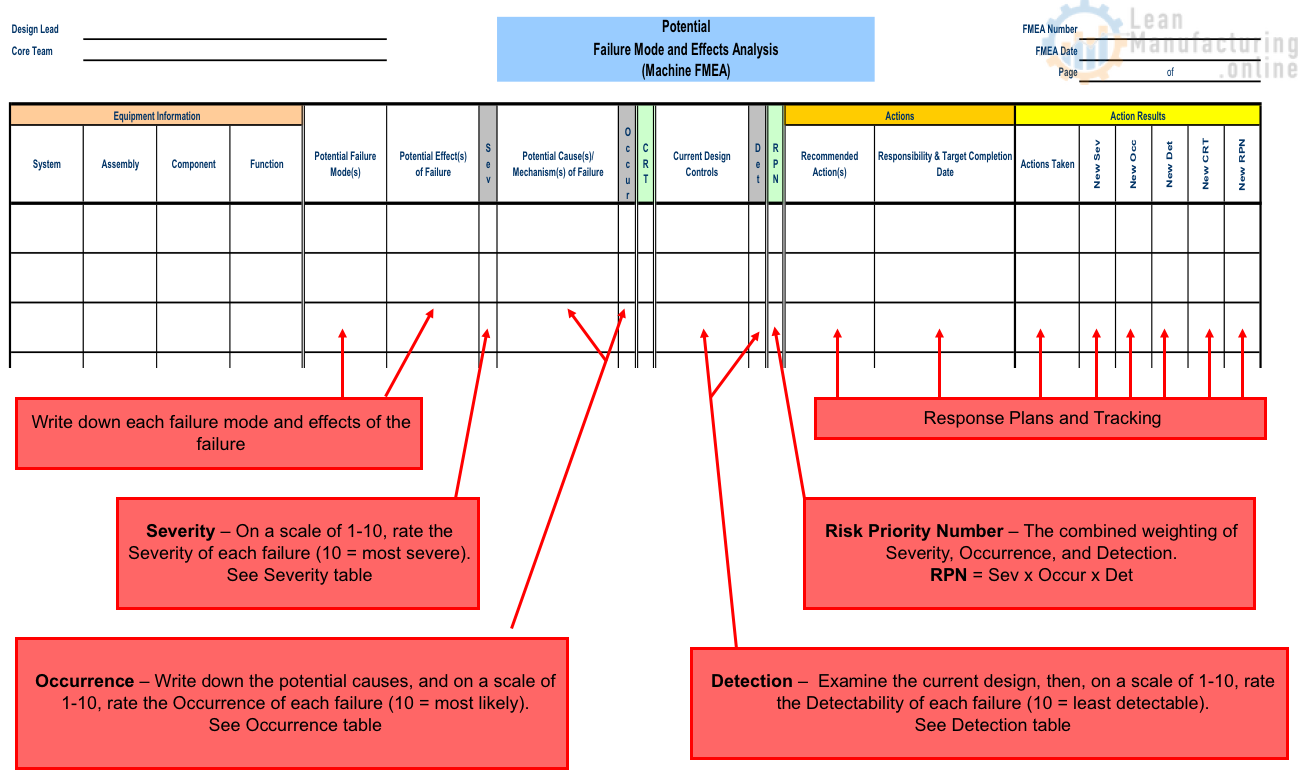

Read More »Failure Mode and Effects Analysis

We should be able to determine whether we need to put detection in place in certain areas and determine how to recover from certain fault conditions.

Read More »Early Equipment Management Procedures Manual

Learner Objectives The main objective of this manual is to be a guideline for training on the principles of Early Equipment Management (EEM). After you have completed your training you should be able to complete the following activities that make up the EEM process. Understand the “Idea Phase” of the…

Read More »Classification of Assets by Criticality

Classifying the Equipment by how critical they are to the process, allows the maintenance planners to better plan & schedule the work required. They can prioritize the work and attend to the most important equipment first, maximizing the available resources and increasing the effectiveness of the maintenance department. This classification…

Read More »