Education and Training

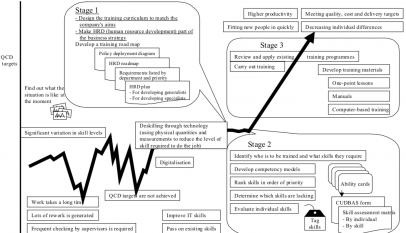

A 6-Step Training and Development Program

The basic policy for training and development in our factory is that improving everyone’s individual abilities helps to improve the company’s business results, as well as giving people a sense of pride and achievement in their work and daily lives.

Read More »The Need for Training and Development

Companies progress by developing their employees’ capabilities and maximizing their ability to work effectively. The object of a TPM program is to build a corporate organization and culture that continuously evolves in response to changes in the economic environment, technical innovations, the introduction of more advanced equipment, and the development…

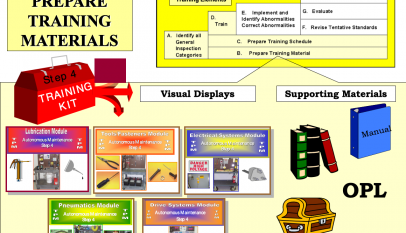

Read More »Autonomous Maintenance Step 4 Case Study

Autonomous Maintenance Blog Education and Training Manufacturing Support Planned Maintenance Training World Class Manufacturing

Implementation Team Values: IntegrityDemand diversity of thought!Responsibility and accountabilityDefine & communicate roles, responsibilities, and actions plans for teams and individuals! 5W & 1H WHAT: Major Stoppages/BreakdownsWHEN: DailyWHERE: Packaging LinesWHO: MechanicWHICH: N/AHOW: Not Enough time to Eliminate SUMMARY OF PROBLEM:Mechanics do not have enough time to Eliminate Major Stoppages/Breakdowns that occur…

Read More »Standards of Leadership – Quick Reference

Growth Mindset This is competitive leadership. Taking the lead in the marketplace versus following. It’s a positive attitude about the company’s future – glass half-full – but it’s realistic. It’s passion for winning. Winning defined as gaining market share. It’s placing a fresh emphasis on innovation – challenging the status…

Read More »