Manufacturing Support

Chapter 10. TPM in Administrative and Support Departments. Part 1

1. The Need for TPM in Administrative and Support Departments 1.1 Why TPM is Needed – the Background Modern advances in computer and communications technology have created a world in which all kinds of information can be exchanged in real-time all over the globe. This has given added impetus to…

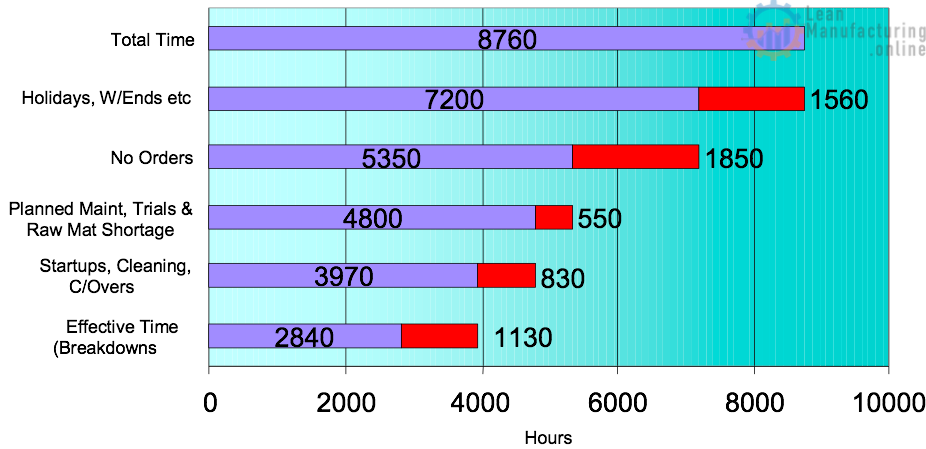

Read More »Loss Trees and Loss Deployment

What are Loss Trees? In general, Loss Trees are simply a listing of the losses (inefficiencies) which may exist in a factory production process. Loss Deployment is a cascade process that looks initially at the overall factory losses than increasingly at a more detailed level down to a packing line…

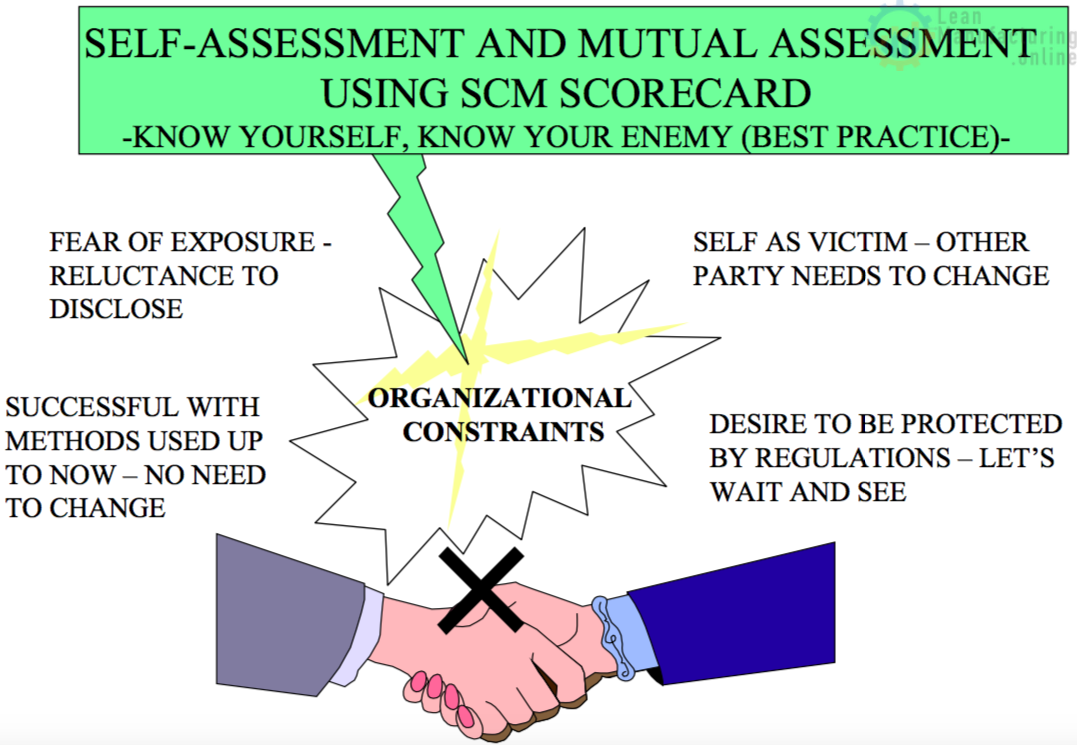

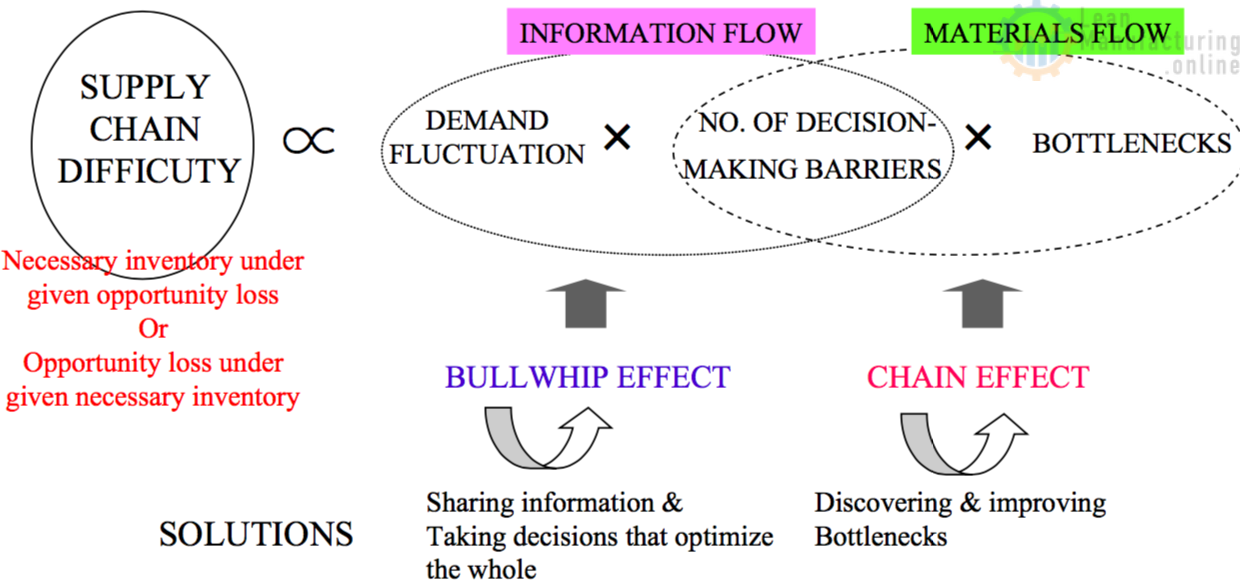

Read More »Supply Chain Management (SCM) and its relationship to TPM. Part 2

SECTION 3 SCM AS TPM LEVELS 2 AND 3 LEVEL 2 AND 3 GENRES AS SEEN IN THE TPM AWARDS THE STRENGTHS AND LIMITATIONS OF TPM AN EXAMPLE OF THE INTRODUCTION OF SCM AS A NATURAL EXTENSION OF TPM (FROM SOURCING UNIT THROUGH DISTRIBUTION TO RETAIL OUTLET) THE DIRECTION OF…

Read More »Supply Chain Management (SCM) and its relationship to TPM. Part 1

SECTION 1 WHY DO WE NEED SCM? SCM is now the accepted and ordinary business model, but … Making more the supply chain visible enables naturally us to reduce both lead times and costs SCM – THE ACCEPTED BUSINESS MODEL Since the late 70s, we have been in an era…

Read More »